,

|

| This is the check valve that allows the line to stay pressurized so the system can respond faster. The newest AEM systems have this valve built into the nozzle. |

Because of these issues, we quit using water injection, or at least not tuning with it to improve performance because we did not trust the reliability of the systems available at the time and the fact that it was difficult to determine how consistently the systems were actually working.

|

| This is the system controller. Set up is easy, just turn the screws to control flow onset and maximum point. The system arming switch is the red rocker switch. All of this is tucked neatly away in the center console. |

Move forward a few years and AEM Electronics enters the market. The AEM water/methanol injection system was more robust with built in check valves and cleanable nozzles with built in filters less sensitive to clogging. An electronic controller with self diagnostic capability made it easy to control water onset with boost pressure and volume of water injected. The AEM system also featured a constantly running recirculating water pump for very fast response. The system also featured big large element cleanable filters in line and the ability to detect an empty water tank.

To see MotoIQ’s test of the AEM Water/Methanol injection system click here!

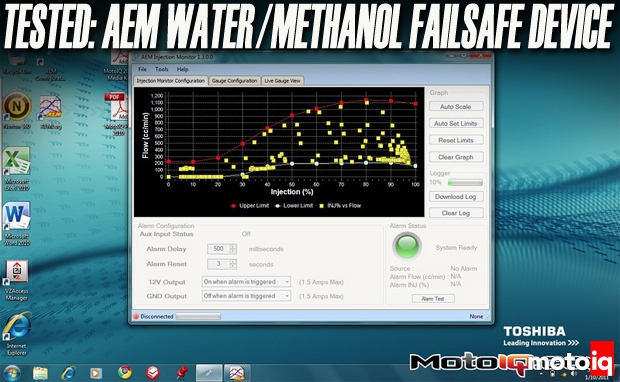

Perhaps the best thing about the AEM water/methanol injection system was the feature of the optional flow meter and water flow gauge. The meter did more than measure system pressure as it could actually measure flow. This way it was easy to confirm that the engine was actually receiving water and that water was not flowing when it was not supposed to be. This was great and we finally had a system we could trust. The meter was compact, accurate even at low volumes and easy to install.

|

| The basic AEM water methanol injection systems are shown here! |

2 comments

Hello! I want to buy this device!! Do you have it in stock! AEM 52mm Water/Methanol Flow Gauge 0-1000cc

We don’t sell parts but many dealers do, google is your friend