An engine works best when the right things happen at the right time. Say your spark fires before your pistons are in their right spots—you might embarrass yourself on the dyno. You might even end up with a scenic view of your bottom end. The relationship between an engine’s crank and its cams is no different. The rise and fall of its pistons has to sync with the opening and closing of its valves, which happen to be controlled by its cams. This is even more important to pay attention to once aftermarket cams, adjustable cam gears or other mismatched components—each with their own tolerances—are introduced as well as once an engine’s block or cylinder head have been resurfaced. Small tolerance changes or amounts of material removed will change the distance between the cams and the crank, which will alter their relationship with one another and affect cam timing. Even a new timing belt, timing chain, or tensioner can affect cam timing. All of this should be enough to make you want to degree your cams.

Cam degreeing—or “zeroing in” cam timing—is a good way to make sure that your cams are performing the way they ought to and that your piston-to-valve clearances are what you think they are. It’s also a good way to make sure that your valves open and close at precisely the right time. The process positions a cam’s centerline—in crankshaft degrees—exactly where the cam manufacturer says it should be. It’s a process that should be done whenever aftermarket cams are swapped into place or any time the distance between the valves and pistons has changed—like when using a thicker or thinner headgasket or when a head’s been milled—before firing it up. The consequences of not doing so are piston-to-valve contact or, at best, lost power.

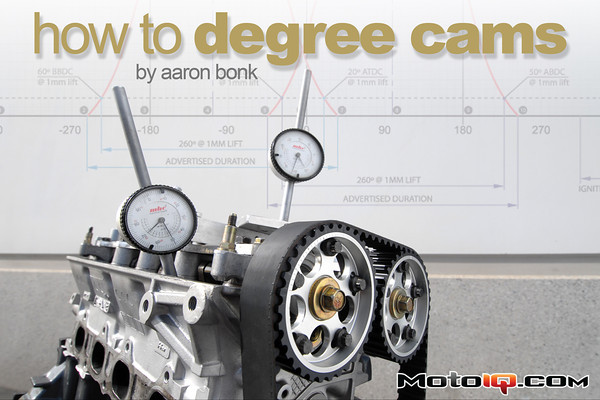

You’ll need adjustable cam gears to do all of this as well as a degree wheel, a dial indicator, and some basic hand tools. But don’t think that cam degreeing has anything to do with dialing in your adjustable cam gears to some magical, predetermined setting. Your cam gear manufacturer has no idea how many times your block’s been surfaced, how much your head’s been milled, or whose cams you’ve got. Neither does the kid on the innerwebs whose got “the same setup” and assures you that a couple of degrees of advance on your intake cam is exactly what you need. To be sure, cam degreeing is more than simply the twist of a couple of adjustable cam gears based off of where the cam gear maker says “0” is. Cam degreeing ensures that the cams are in their correct position. For your engine. Nobody else’s. The guesswork’s eliminated.

|

| Cam degreeing is more than a twist of a couple of adjustable cam gears based off of where the cam gear maker says “0” is. The process ensures that a cam’s centerline is in its correct position for your particular engine. If you’ve got aftermarket cams, cam degreeing is essential for optimum performance. |

Before degreeing cams, though, you’ve got to understand some cam fundamentals to help better see why all of this needs to be done. A good grasp on the four-stroke process won’t hurt either.

THE FOUR-STROKE PROCESS — The four-stroke cycle gets its name from its four piston stages: intake, compression, power, and exhaust. For every 720 degrees that the crank spins, each of the engine’s pistons travels up and down twice. Meanwhile, the valves, carefully controlled by the cams, introduce air and fuel into the cylinders and let exhaust gases out. In the real world, the precise beginning and end of each cycle is pretty foggy because of cam profiles and all sorts of complicated physical and chemical constraints. Instead of 180-degree increments, an engine’s valves typically remain open far longer in order to introduce enough air and release enough gas. Proper valve timing is critical to how well the four-stroke process works, and proper valve timing begins with cam degreeing.

|

| Degreeing cams can be pretty confusing if you don’t have a grasp of the four-stroke engine cycle. Proper valve timing is critical to how well the four-stroke process works, and proper valve timing begins with cam degreeing. |

CAMSHAFTS — They look simple, but cams are some of the most complex parts of an engine. In simple terms, cams are long, cylindrical-shaped shafts containing several irregular-shaped lobes that convert rotary motion into reciprocating motion. They’re driven by a belt or a chain, which links directly to the crank by a pulley. When spun (rotary motion), their lobes impart their eccentric shapes onto their corresponding rocker arm pads. Rocker arms actuate the cylinder head’s valves (reciprocating motion) in an orchestrated fashion, relative to engine speed, and synchronize with the engine’s piston movement at precisely the right time. Although, an engine’s valvetrain is made up of all sorts of components, only the cams determine when the valves open, for how long, and when they’ll close. As a result, an engine’s cams dictate its power curve and at what point in the RPM range the engine will produce maximum horsepower and torque. If a cam isn’t degreed, and therefore not positioned exactly where it needs to be, it’ll never perform the way it should.

|

| Cams may seem complicated, but their job is quite simple: to convert rotary motion into reciprocating motion. When spun (rotary motion), a cam’s lobes impart their irregular, eccentric shapes onto their corresponding rocker arm pads, which actuate the cylinder head’s valves (reciprocating motion). All of this has to synchronize with the engine’s piston movement at precisely the right time, which makes cam degreeing even more important. |

6 comments

Hi there, got a couple of kelford 166852 sr20ve cams, just wondering when you degree sr20ve cams is the spec sheet go off the smaller outer lobes or the larger centre lobes. If its the larger lobe (which i believe so) how do you degree them on the bench with that centre part of the rocker spungy(no oil pressure to firm it).

I would contact Kelford and ask which lobe they degree off of. Personally I would do the low rpm lobe off of the sheet.

Great explanation.

I degreed my cams according to this procedure in my B18CR. Cams are Skunk Tuner Two’s.

My question is, if the cams are removed and reinstalled without disturbing the sprockets, is it necessary to redegree?

No

Hi. If a Head/cam has been degreed on one particular engine, and you put that same head on another engine with different headgasket etc, is it then nessecary to degree the cams again ?

Yes