,

The JE piston rings are still in amazingly good shape. Note how blow-by staining on the piston skirt is non-existent, and the second compression ring has almost no wear. With a long stroke and high revs, non-WPC treated ring wear is usually severe, and it is very difficult to get a ring to hold compression for this long. Like I mentioned before, the engine had excellent compression and leakdown numbers when pulled. The piston wrist pins and piston pin boss were WPC treated and showed no visible wear at all.

The Crower mechanical roller cam has essentially no wear at all. The WPC treated areas show some light burnishing, but no measurable change in dimensions. The cam could easily be stuck right back in for another year of use. This is pretty amazing because it is a pretty radical cam with fast lobes and a high installed seat pressure. These sort of cams wear faster than mild streetable cams.

A close-up view of the cam lobes. We are just going to re-WPC treat it and stick it right back in!

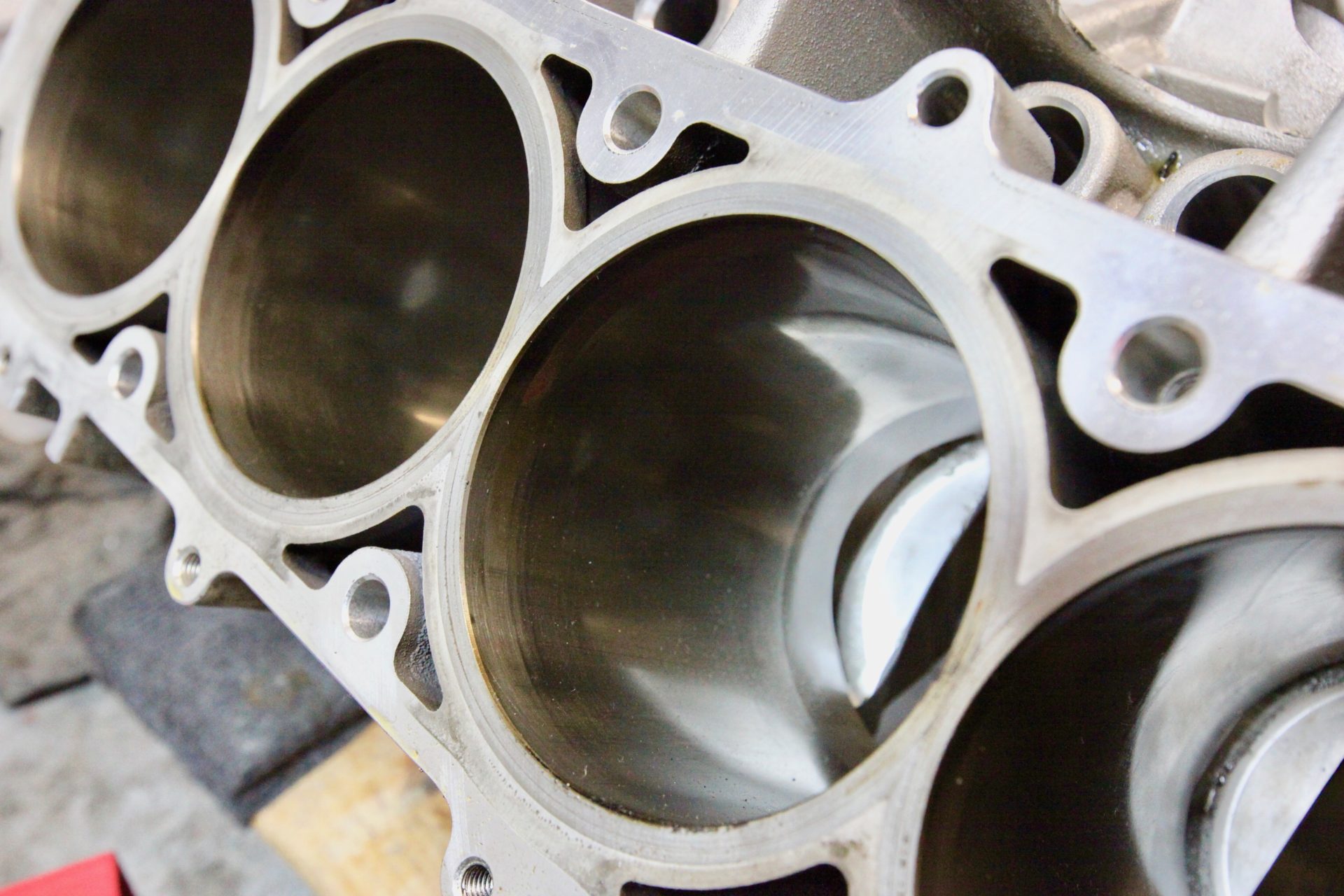

We WPC treated the cylinder bores with good results. You can still see the honing marks on the block cylinders’ heavily loaded thrust side! This is amazingly low wear for a long stroke engine that sees up to 7700 rpm.

The bores could be honed and reused but we are choosing to rebore by 0.005″ for a complete bore cleanup. At this rate, we will get many years of service out of this block.

The wear of the bore and pistons is very low considering that the engine is run on ethanol. Ethanol has very low lubricity compared to gasoline and a strong solvent effect that removes oil from cylinder walls, reducing lubrication between the piston and cylinder. Most ethanol or methanol engines exhibit shorter service life for these reasons. Thanks to WPC, we still have an excellent life for these areas!

OHV engines put a lot of side load on valve stems which accelerate both stem and valve guide wear. A fast-acting roller cam makes this much worse. Ethanol fuel does as well.

Our engine’s valves have been WPC treated and have little wear on the stems. The valves are still plenty good, but we change them for preventative maintenance reasons. Our super expensive engines built by the other guys had frequent valvetrain failures, but we have not.

We also WPC treated the valve springs to help improve the fatigue life. Previously, we would have to change the valve springs every 4-5 events or suffer from breakage and risk dropping a valve. Now we can run 10 plus events without an issue.

Related

2 comments

I would like to know more about WPC.

This is wonderful technology.

How Can I get benefit of WPC Technique and what will be your terms & Condition.

The link to WPC and articles explaining about WPC in detail are in this article.