|

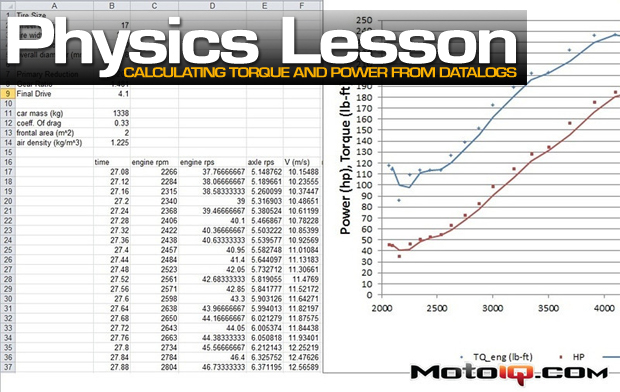

Physics Lesson – Calculating Torque and Power From Datalogs

By Khiem Dinh

Khiem Dinh is an engineer for Honeywell Turbo Technologies at the time of this writing. All statements and opinions expressed by Khiem Dinh are solely those of Khiem Dinh and not reflective of Honeywell Turbo Technologies.

The motion of cars is ruled by physics, so using some basic physics and data enables us to calculate cool things. Everyone likes cool things right? The modern automobile has electronics that gives us the ability to gather useful data letting us calculate useful things. In this case, we’re going to calculate torque and horsepower making ourselves a virtual dyno.

I recently had a Hondata KPro installed allowing me to get the necessary data. To calculate torque and horsepower, only engine speed and time need to be datalogged. With just those two parameters, we can apply good ole F=ma (Force = mass x acceleration). We do need to know other parameters specific to the car in order to perform the calculations: tire size, vehicle weight, gear ratios, final drive, coefficient of drag, frontal area, and air density.

|

First, we need to look at the forces acting on the car. We have the force at the wheels pushing the car forward and the force of aerodynamic drag pushing on the car in the opposite direction. The difference between the two is the remaining force providing acceleration. Terminal velocity is the situation where the drag force equals the force at the wheels resulting in zero force for acceleration. I called the force at the tire a net force as there are also frictional losses; there’s not really a good way to decouple the frictional losses from the force put down at the tires (which I called the gross force), so I lumped them together into a net force. This is the equivalent of measuring torque at the wheels on a chassis dyno where the car is strapped down to rollers.

|

The basic equation we need to calculate torque and power is F=ma. We know the mass of the car, so we need to calculate the acceleration of the car which gives us the force. Remember the engine speed and time we datalogged? We’re going to use that information to calculate velocity giving us acceleration and drag force. Knowing those two things gives us the net force at the tires.

|

|

To get velocity, we need to know how fast the tire is spinning and also the tire’s circumference. Calculating the circumference of the tire is a simple matter of plugging and chugging the tire width, aspect ratio, and wheel diameter. The rotational speed of the tire is calculated by dividing the engine speed by the gearing. In the case of the S2000, it has a primary gear reduction in addition to each individual gear ratio and the final drive.

Now that we know velocity, it’s a simple matter of calculating acceleration. From acceleration, we get the net force at the tire. Using the value of the net force and the radius of the tire, we can calculate the torque at the tire. To convert to torque at the engine (as measured at the wheels/tires such as most chassis dynos), the value of the torque at the tire is divided by the gearing. Once you know the engine torque, horsepower is just an equation away.

|

5 comments

You have a wrong formula

Torque = force x radius

You are absolutely correct, thanks for catching that! Should have been: Force = Torque / Radius

Can you please put an example with a given sample data ?

Here’s a link to my spreadsheet. It has my S2k, my old Evo, and someone’s 991.2 Porsche 911 data I analyzed. https://docs.google.com/spreadsheets/d/1hlYetvuYS-86bg_TnIAUULvfg5nBapltaagVwJTBM8w/edit?usp=sharing

Thanks for sharing! I’d love to take some inspiration from you for EV lessons I am making. Do you have any EV dyno data to share? Also, I am having trouble opening your github links, like the one that mentions Brad Barnhill or the one to download Virtual Dyno. Can you repost active links for me, please?