Many times I've struggled with stubborn bolts, cursing car manufacturers wth a number of expletives in languages I didn't know I could speak. Stripped, rusted, or fused, these bolts can make any breaker bar retire early and hit happy hour. Unfortunately if I ever wanted to mod any of my cars, my only other option was blowing off some steam… well, hot air really. My air compressor is not only convenient, but necessary.

Compressors come in many shapes and sizes. Most of the larger compressors can run longer, more efficiently, and have tanks to store the compressed air for maximum use. Compact air compressors don't usually have storage tanks and must run continuously to provide an adequate air supply. They are good for small jobs, anything from refilling tires to blowing up inflatable dolls, right Kojima? 😉

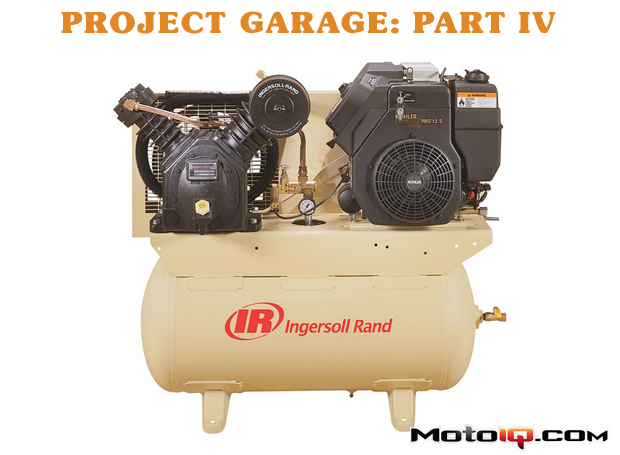

|

| This is like the grand daddy of air compressors. It's a two stage, two cylinder splash lubricated belt-driven (dirty talk, I know!) air compressor with 14 horsepower and pushes 25cfm at 175psi (seriously!). You'll have to cough up a few g's to own this baby. |

Air compressors convert electric energy into kinetic energy. Some use rotating impellers to generate air pressure. Most use a reciprocating piston to increase air pressure by reducing the size of the space where the air is contained. A conventional piston compressor uses a crankshaft driven by an electric motor or gas engine as well as a connecting rod, piston, cylinder and valve head. The valve head contains the inlet and discharge valves. Air enters the inlet valve and fills the space above the piston. When the piston moves up, it compresses the air, which exits through the discharge valve into the tank or an air hose.

1 comment