Project Low Buck SR20DE Part 2

Completing the bottom end

In our last edition of Project Low Buck SR20DE, we stated our goals to obtain a decent amount of naturally aspirated horsepower and good track day drivable reliability from an underdog plain jane SR20DE without breaking the bank. Fulfilling these goals would also create an engine with excellent street driving characteristics as well. All of our engine work will be done on the cheap with a tight budget in mind but with plenty of attention paid to minor details that can really help an engine live under the stress of track day pounding, perhaps the most abusive environment that a grass roots enthusiast will subject his engine to. Unlike drag racing, a car driven on a road course is pounded to the redline for 20-40 minutes at a time; this sort of use requires attention to detail if an engine is to live.

In our first installment we selected Eagle Rods and SR16VE pistons for our build. We modified the pistons for more piston to valve clearance and applied optional thermo barrier and anti wear and friction skirt coating. For the budget minded, drag racers or for pure street use, the stock rods will also work pretty well being rock solid safe to 8000 rpm. You can live without the coatings and piston machining as well to save a few bucks and still obtain respectable results.

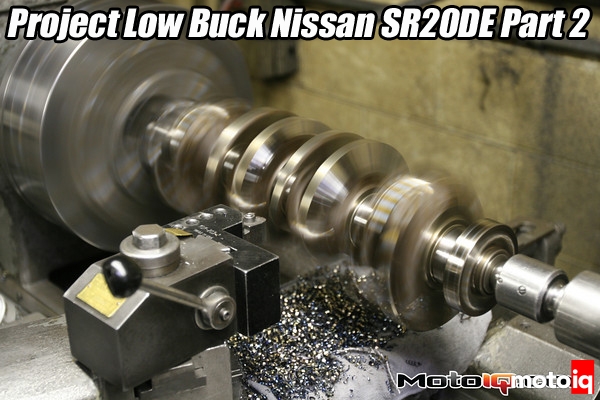

Since we are retaining the standard bore with the SR16VE pistons, we avoided the expensive task of boring the SR block oversize. The SR20 block suffers from severe bore distortion when the head and transmission are bolted in place. The bore can distort as much as 0.0015”, an amount that can really affect ring seal or even contribute to piston scuffing. Thus it is important to use a deck torque plate and to bolt a transmission bellhousing to an SR block when it is being bored and honed to keep the bores roundness accurate in as used conditions. Not too many shops in this country can do this sort of work on an SR and packing and shipping your block to places like Jim Wolf Technology in California or Mazworks in Florida can be very expensive.

|

| Our SR20DE block had very little bore wear so we just ball honed the bore to deglaze it and took a little off the deck to clean it up for good gasket seal |

Fortunately in most cases, a stock SR exhibits very little bore wear, even in 100,000+ mile motors. In our case our free core engine was pulled from a friends NASA SE-R Cup car in which it had been raced for two seasons and was replaced because it was getting a little tired. Although the rings were worn, the bore was in excellent shape. We simply used a ball hone to clean the bore up so new rings could seat easily and we were done. The Swain coating we applied to our piston actually brought our piston to wall clearance in on the middle-tight side of stock, perfect. Finally, Technosquare then lightly decked the block, removing about 0.003” of material to assure a flat surface for the head gasket for optimal sealing using very fine cuts for a smooth surface that would be compatible with a MLS type head gasket.

|

| JWT machined this groove on the main saddle to feed the rod bearing for more oil flow for more degrees of crankshaft rotation. SR20VE and GTI-R main bearings have more oil feed holes to take advantage of this groove. The block is also spot faced and tapped for the piston cooler nozzles shown here. They are the things with the nozzle pointing toward the bore |

SR’s are known to be hard on Rod Bearings. If the engines oil is constantly monitored and maintained right at the full mark on the dipstick, no more and no less, usually the bearings are trouble free even under hard use. However, later versions of the SR20, like the SR20VE and some turbo SR20DET engines have improved oiling for the rod bearings. This is done by adding a groove to the main bearing saddle in the block that intercepts the oil feed hole coupled with the use of SR20DET main bearings which have additional oil feed holes in the upper bearing shell. This assures that the rod bearing feed holes in the crank receive a good supply of oil for a full 180 degrees of crank rotation.

Jim Wolf Technology performs this modification to SR20 blocks that don’t have the groove from the factory using a cutoff wheel and a simple guide jig. This could be duplicated by anyone with a little skill and patience. This mod is not absolutely needed and many a fast SR has been built without it but it is a good detail to help engine life under hard use.

|

| Our block with the rod bearing oiling groove and piston cooler squirter |

Next piston coolers from an SR20DET were installed. Piston coolers are nozzles that shoot oil from the main galley up to the bottom of the piston to help keep them cool under hard use. Aluminum looses much of its strength past 350 degrees and piston coolers help a high compression engine stay cool under extended wide open throttle use. Keeping the piston cool can also reduce the chances of an engine experiencing detonation under hard use. The piston coolers have a spring loaded check valve to make sure that oil pressure isn’t lost under low rpm and idle, but open at higher rpm when the oil pumps bypass circuit is activated. The SR20 block has bosses for the piston coolers already cast in place stock. The bosses must be drilled, tapped and spot faced so the coolers can be installed.

|

| When adding piston coolers be very aware of this notch at the bottom of the piston skirt. This is there to clear the piston cooler nozzle. Put the piston in backwards and the skirt will shear off the nozzle and you will loose oil pressure. Ouch |

Jim Wolf Technology routinely does this operation and it is pretty simple for any machine shop to do. Care must be taken to spot face the bosses enough so the coolers body clears the crank and the nozzle clears the piston skirt. SR16VE pistons have a notch in the skirt to clear the coolers but if you use some other piston, be careful and check this clearance when assembling the engine. Quite a few people have made this mistake and later wonder why their engines suffer from low oil pressure when the piston skits shear off the nozzles! Like some of the other mods discussed here, piston coolers are not absolutely needed for street or drag use but are a nice low buck touch to help reliability under extreme conditions. The Nissan factory also uses piston coolers in its high compression NA motors so perhaps there is a good reason for this.

5 comments

who ever wrote this sucks

Hahaha got any better ideas?

What ever happened to this Mike?

I have some spare parts and was thinking of making an NA SR20 setup and was curious how this turned out.

I have some old SCC articles about your B14, but it’s bits and pieces here and there and not comprehensive.

It ran for years and that car is long gone.

Great Project that you have going on here. Love the detail and the photos they are a class act. Keep up the great work!

300zx Nut. – Alan.