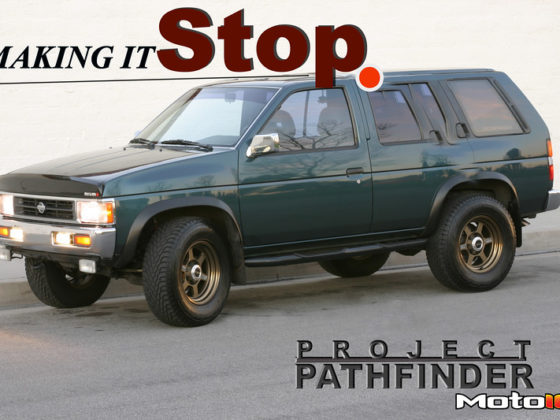

,

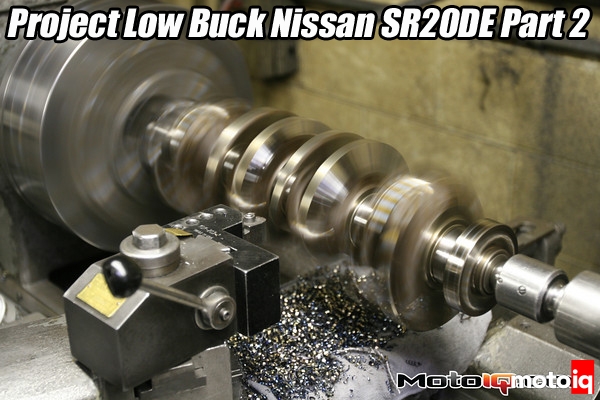

Next we focused on the crank. Fortunately the stock forged steel, fully counterweighted SR20DE crank is one of the stoutest units in the business and really doesn’t require much work at all to sustain the highest power and revs. Usually an SR20 crank has very little journal wear and does not require much work for reuse. In most really low buck applications, it can simply be inspected and reused! However since we anticipate some hard use, we sent out crank to Joe Castillo of Castillo’s Crankshafts to have the journals polished, be balanced and to have the counterweights lightened and profiled for less windage drag. The last step is especially not really necessary.

|

| Castillo’s Cranks lightened our cranks counterweights to equal the lighter weight of our pistons and rods. This profiling also reduces windage drag |

After magnaflux checking our crank for cracks, then inspecting it for other possible damage and straightness, Castillo’s put our crank on a lathe and profiled the counterweights. This removed one pound of weight and gave the counterweight a more aerodynamic contour. This should help reduce windage power losses in the crankcase as the crankshaft has to spin in a dense cloud of turbulent air and oil. Since we anticipate a lot of high rpm long term use, we did not go crazy with lightening the crank; we simply removed from the counterweights about what was reduced on the pistons and rods. After machining, Castillo’s shotpeened the crank to improve fatigue strength.

|

| Our crank after the Castillo’s treatment. Balanced, lightened, oil holes chamfered, passages cleaned and plugged, mircropolished, shot peened and WPC treated |

Castillo then drilled out the oil passage plugs in the crank to facilitate cleaning and tapped the holes so screw in hex plugs could be used. This is much safer and more secure than the stock pressed in plugs. The journal oil holes were chamfered and teardropped to create a reservoir for oil from the main bearing feed to improve oil flow to the rod bearings. The bob weights of the same weight as our rods and pistons were bolted to the crank and the whole assembly was dynamically balanced. As a final step all of the cranks journals were micro polished to reduce friction and help improve bearing life. Although all of these steps are not needed in a low buck engine, they are not particularly expensive either.

|

|

| Our piston rings and oil pump gears were WPC treated for long life, less friction and low wear. We also used the WPC process on our crank and block bores |

Prior to assembly we send our crank, rings, oil pump gears, camshafts, cam followers, valve springs and block off to be WPC treated. WPC treatment is a Japanese born process where metal surfaces are bombarded with very tiny ceramic shot at extremely high velocities. Special antifriction additives like tin or zinc powder and molybdenum disulphide are added to the mix and are embedded into the surface. The result is an extremely smooth friction free surface with self lubrication properties. The shot also compresses the metal on a molecular level near the surface, refining the grain, creating a zone where it is very difficult for micro fatigue cracks to propagate. In this way WPC works very much like shotpeening for increasing fatigue strength of parts but on a finer scale. When applied to the crank, WPC improves upon the surface finishing of the journals and toughens the fillets of the crank where most failures occur. On the cylinder walls, WPC reduces friction and the micro dimpled surface helps the rings seat instantly. The dimples hold oil which helps ring and bore life and reduces friction as well.

WPC is a little known secret that sees a lot of use in Champ Car, NASCAR, JGTC and F1 where it is highly effective in reducing friction and improving the life of parts. A drawback is that the process is somewhat expensive and costs around $800 dollars to apply to all of the engines rubbing parts. This is not needed for a budget motor but we have heard very favorable reviews of the process increasing both power and component life from our friends at XS Engineering, Cosworth and in the professional racing world. When we received our parts back from WPC we were amazed by the silky smoothness that they exhibited. We can hardly wait to see how this process works.

We used Calico coated Clevite bearings for the rod and main bearings, using SR20DET bearings for the mains to make use of the extra oiling holes and regular SR20 bearings for the connecting rods. Our friends in the world of professional racing had good things to say about the calico bearings so we decided to give them a try. Clevite bearings are the tri metal type, meaning that lead, copper and zinc are alloyed in various ratios and applied in layers to the steel bearing shell to create a bearing with a wide range of characteristics, a hard bearing for superior load bearing that still has some embedabilty like a soft bearing to make the bearing a little more forgiving for dirt and contaminates. The bearings then have Calicos CT-1 coating applied in a 0.0004″ thick layer to provide some additional protection and friction reduction. The CT-1 dry film lubricant coating is technically engineered to withstand extreme performance pressure. CT-1 coated engine bearings are claimed to increase horsepower and efficiency while extending bearing life.

Strangely enough, most Nissan engine bearings were Clevite but in an effort to become a more green company by eliminating the use of lead, Nissan discontinued their use in the early 90’s. The new bearings with less potential for pollution are vastly inferior for performance, especially in regards to temperature resistance. The eco friendly Nissan bearings begin to deteriorate with oil temperatures as low as in the 280 degree range. It is common for an SR when driven on the track during a hot day to see sump temps in the 300 degree range!

|

| We used Calico coated clevite bearings for a SR20DET so we could get the upped main bearing to have the extra oiling holes for our grooved block. The Calico bearings are much tougher than stock |

With the Calico coated bearings our bearing clearances worked out to be slightly to the tight side of the middle for factory spec, perfect and actually pretty normal for a typical slow wearing used SR motor.

5 comments

who ever wrote this sucks

Hahaha got any better ideas?

What ever happened to this Mike?

I have some spare parts and was thinking of making an NA SR20 setup and was curious how this turned out.

I have some old SCC articles about your B14, but it’s bits and pieces here and there and not comprehensive.

It ran for years and that car is long gone.

Great Project that you have going on here. Love the detail and the photos they are a class act. Keep up the great work!

300zx Nut. – Alan.