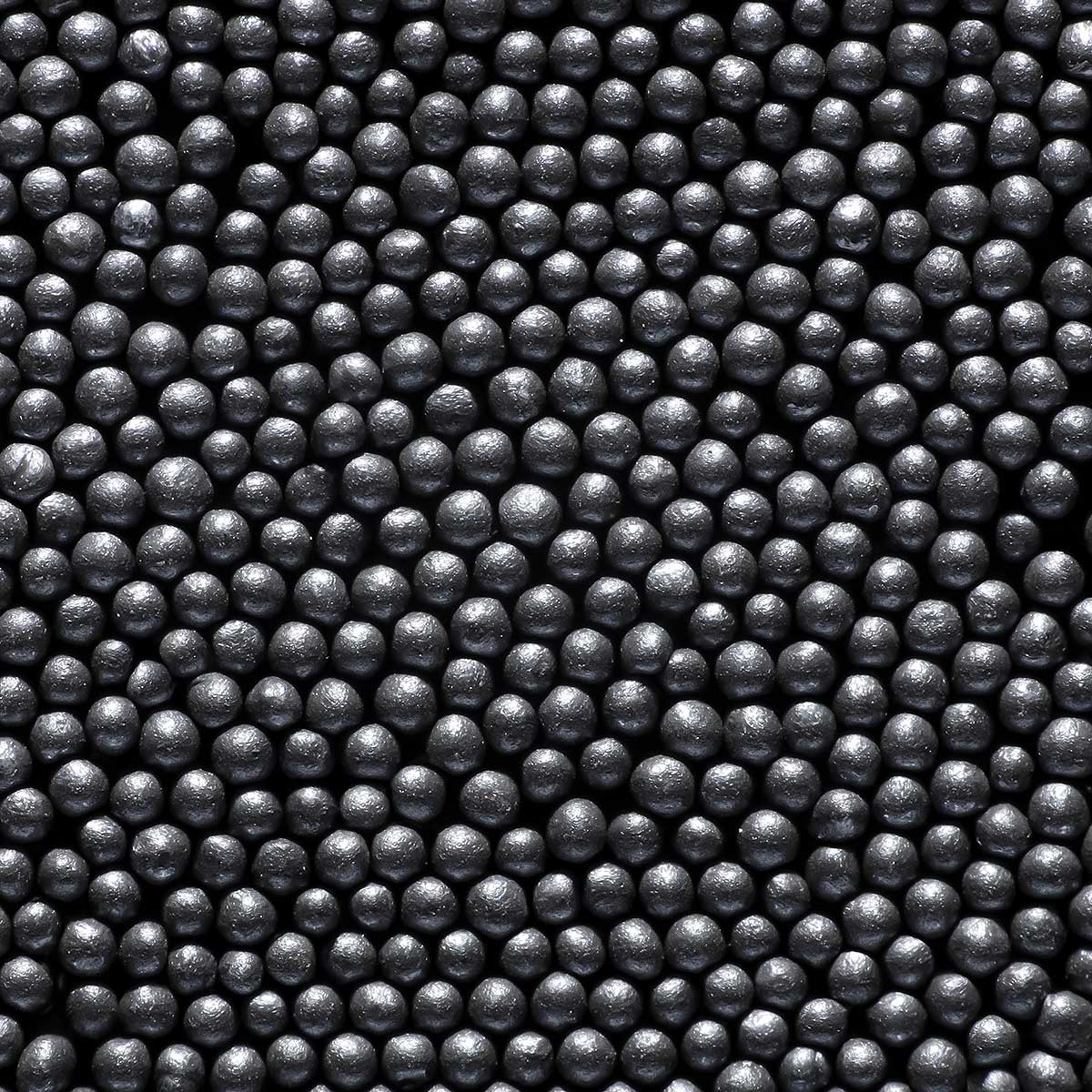

We also do crankshafts and rods. Cranks are done after Magnaflux testing, Jornal polishing, and balancing. Rods are done after Magnaflux. Rods are done after Magnaflux and balancing. Generally, we polish the forging parting line that causes stress risers off the rod before balancing. After shot peening the rods should be resized before WPC treatment. Since the cost for really good racing rods has come down so much over the years, we hardly ever do this anymore but if we had to run stock rods for some reason, this is how we would do it.

Ring and pinions are a part that we treat with shot peening very often. Like transmission gears, you polish the tops and sides of the gear teeth before starting the process.

Racing rods usually come shot peened from the manufacturer nowadays but if they are not, they can be sent out to have shot peening done. When shot peening is done to a rod, it should always be checked to see if the rod needs resizing afterward. Unlike stock rods, it probably will not but it should be checked.

Shot peening is an inexpensive process that can be used to greatly improve the service life of any metal part. There are not any drawbacks to doing it other than cost and possible distortion of delicate parts. These are the reasons why we use it so much nowadays!

Sources

Abrasive Finishing Corporation (AFCO)

CTP Cryogenics

WPC Treatment

4 comments

For ring and pinion prep, would there be any advantage of prepping used parts that have had the surfaces worn in but not abused or would it just be better to start from zero?

New parts that haven’t had any fatigue cycle are the best!

As a certified mecanical engineering consultant specializing in failure analysis for a few wonderful decades, I specified shotpeening for many applications with fatigue failures completely eliminated in many cases. Elimination means an “infinite fatigue life”.

I actualy tried to do what you are asking, shot peen an industrial part that had already seen millions of cycles. And unlike a new part, the peening did not prevent an early fatigue failure.

For those more interested in the subject, this link shows graphically what fatigue life is all about, copy & paste:

https://www.google.com/search?q=material+science+%22fatigue+strength%22&tbm=isch&source=iu&ictx=1&vet=1&fir=DN2333AcH5rVhM%252CEdydFIG2oJms5M%252C_%253BsKz8goNsxDUKdM%252CfIFqo5KR2MpdeM%252C_%253B6lgWtseZC8cxsM%252Cx8BcYZ44k9-XRM%252C_%253BR5GA6Skq-oIV0M%252CqJ3IIISFS-eu3M%252C_%253BY2VREyjF6iPxkM%252CEdydFIG2oJms5M%252C_%253ByUyI_w4Q_oKwIM%252CM4eXXAI42Xx-nM%252C_&usg=AI4_-kSSMLA0mncBSHoAfLI2U6MK0YZ0Lg&sa=X&ved=2ahUKEwinr9jNjPH5AhX7rIkEHel6BCIQ_h16BAhfEAE#imgrc=sKz8goNsxDUKdM

Do you have a more specific link? This is just a general one.