,

Back in 1977, Renault started to enter F1 races with a single turbo V6 engine. It didn't really shine in terms of performance, but in 1978 the car finished in the top 10 and scored its first points. Then in 1979 the turbo Renault got its first pole and its first win. Needless to say, other engine designers saw the light and Ferrari and BMW soon followed suit in 1981 with turbo engines of their own.

At the time Cosworth was still dominating F1 with the normally aspirated 3.0L DFV so Cosworth did not feel the urgency to develop a turbo engine immediately. It wasn't until their diminishing wins started to become apparent that Cosworth started to get off their high horse and start on a turbo engine. The rules at the time stated that an engine could have a maximum capacity of 3.0L if normally aspirated and 1.5L if supercharged. These displacement rules were written in 1966 when turbocharging automotive engines wasn't really even considered. Keith Duckworth (the “worth” in Cosworth) pretty much was against the entire idea of turbocharging in F1 because he believed it was technically against the rules. What Duckworth said was that a turbocharger was actually a second motor that shared the combustion chamber inside of the engine and of course two motors were not allowed in F1. To further his point, Ferrari was injecting fuel directly into the turbine section of the turbo (anti-lag) effectively converting a turbocharger into a gas turbine and turbine engines were not allowed in F1 either. While Duckworth's points are probably valid (you gotta remember that a turbocharger on a gasoline engine was a relatively new idea at the time) to some degree, the rulemakers in Paris still allowed turbochargers.

Cosworth's first attempt at a turbo F1 engine in 1983/84 was actually based on the Cosworth BD alloy 4 cylinder engine block. Duckworth decided the BD's alloy block would be ample for the original power goal of 650bhp. It was an elaborate setup with an exhaust driven turbo and a second turbo driven by a Ford CVT transmission via the crankshaft. The turbos were staged for big boost (5+ bar absolute). All of it was controlled via ECU which was super state of the art back in those days. It must have been a pretty damn big piece of hardware based on 1987 sized electronics to control all of those devices. The standard BD cylinder head had to be redesigned for boost and flow, but in the end the engine wasn't able to deliver since the horsepower targets kept increasing. Originally the turbo F1 engines from Renault, Ferrari, and BMW were running gasoline, but the rulemakers allowed “rocket fuel” which was actually gelled toluene.You know for damn sure it burnt super slow if it was gelled so it must have had some crazy high octane equivalent. With the new rocket fuel, the other engine manufacturers were already surpassing 800bhp in 1985. This 1.5L BD based 4 cylinder engine with staged turbos was bending crankshafts at 3.0 bar (absolute) boost @ 11,000rpm. Even with a redesigned crank and flywheel the complexity of the turbo setup and transmission was probably a complete clusterfcuk. I'm sure the engine only having 4 cylinders was probably another limitation for increasing power beyond 650bhp reliably. You have to remember that this was 1987 before the time of 3D modeling, FEA, simulations, etc. While Duckworth did redesign the clutch and flywheel to live at that power output, it was clear that it was going to be an uphill battle with a 4 banger. The good old boys in NASCAR back then probably weren't making 650bhp out of their 5.7L small blocks yet and here was the F1 crowd playing with 1.5L engines.

After securing financial support from Ford USA, Duckworth, Mike Costin (the “Cos” in Cosworth), and designer Geoff Goddard went back to the drawing board. What they whipped up was a 120 degree 1.5L V-6 with alloy block and heads with Ford badging. Duckworth was spending more time at home having cashed out by selling the company to UEI so Goddrd took the reins and designed the bulk of the GBA with weekly visits to Duckworth at home. The first component drawings were started in December 1984. By August 1985 the Cosworth GBA was first tested in a car. That's pretty damn fast for a clean sheet engine design isn't it? Initially there were some engine block issues, but after some revisions the engine became very reliable at 1000bhp and was run at more than 1200bhp in qualifying. How's 800+bhp/liter for strength? According to Cosworth lore, the engine ended up being more reliable than the Honda VTECs.

If you are an internal combustion engine nerd like myself, then you'll probably dig “Cosworth: the Search for Power” by Graham Robson. I believe the 5th edition is the latest. You probably don't want to read the 6th edition (it doesn't actually exist) because then you would just be reading about Cosworth's downsizing and diversification (read doing business outside of motor sport) and the decreasing size of the motorsports as a whole which blows big time. Anyhow it really is an excellent book filled with stories, interviews, famous quotes from Duckworth, and behind the scenes stories of many of Cosworth's historic race and production engines. Most of what I wrote above I got from Robson's book, mixed with some question asking at Cosworth and some of my own opinions. Chances are you won't find books like this on any of the other race engine manufacturers because…well because their histories probably just aren't that interesting. Their stories would all just read “…left Cosworth in 1988” or maybe “…left Cosworth in 1994”, etc.

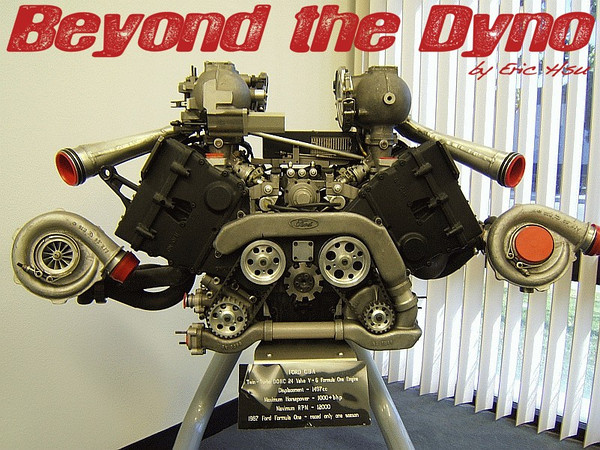

We have an actual GBA show engine in our conference room. Check it out:

The two upper pulleys are probably crank driven by gears inside of the alloy front cover. The lower left pulley is the multi-stage oil pump and the lower right hand pulley is the water pump and alternator which are driven by a common shaft. Check out the old school 9 tooth crank position sensor.

At the back of the engine you can see the distributor, coil in the center of the valley, and the 7.25″ clutch. I'm guessing that Magneti Marelli igntion coil is super heavy duty judging by its size and the fact that it has to ignite the cylinder pressures of a 800bhp/liter engine with extremely short dwell times at 12,000rpm through igntion wires, distributor cap, and rotor. I'm not sure if they are using a 7.25″ clutch because it made too much power for a 4.5″ racing clutch or if 4.5″ racing clutches and modern friction materials did not exist yet.

Here's the LH exhaust cam position trigger. Or at least that's what I think it is. The pickup sensor isn't present, but it looks like that thing could lop off your finger if you weren't careful.

The turbos are Air Reseach units. For you young guys, we call them Garretts today. The compressor housing looks like it is just cast aluminum and pretty closely resembles a T04B in size. Perhaps they weren't casting magnesium yet for compressor housings. Khiem, why don't you look up that compressor cover part number? It's 444852-5. This is just a display engine so this turbo may not have been the final 1200+bhp qualifying spec turbo. For show engines, just about any version of a part or engine can be thrown together.