,

|

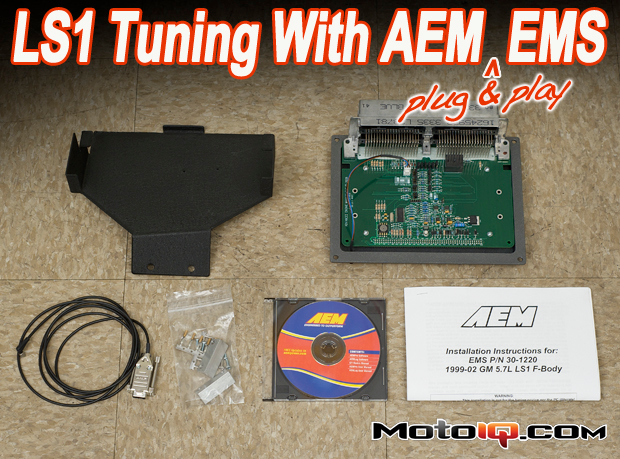

| In GM cars and our RX-7 the ECU installs in the engine compartment. Here we drop the ECU in place on Technosquare’s dyno. The operation literally only takes minutes, even including the wiring of our wideband O2 sensor. |

Now we were ready for tuning. Since the supplied base map should be relatively close for a stock engine we did not make many drastic changes. Since we were going to be doing some tuning on the dyno (we used Technosquare’s Superflow load based dyno, a good dyno for tuning) we initially took 15 degrees of timing off of the entire ignition map to be conservative as we will work back up to minimum best torque timing values on the dyno. We set all 8 injectors to trim off of the single wide band sensor and slightly modified the target AFR table based on experience of what air fuel ratio is appropriate for the rpm and load, the supplied table is close but we did do some initial tweaks to it. We also modified the main fuel map accordingly as well.

We cranked the engine and adjusted the start fuel until the engine started and adjusted the main fuel map once the engine was running to reach the appropriate air fuel ratio of 14.7:1 with the 02 sensor correction being less than 10%. We also adjusted the idle correction percentage vs target idle table by setting idle targets to every value between 800 to 2000 rpm in 200 rpm increments to set the base idle % so the base idle correction would be less than 5-10 with no load such as AC, alternator, power steering, etc. Finally we set the target idle speed vs coolant temperature curve and waited until the engine was fully warmed up.

|

| Tuning was done on a laptop via the serial port. With the initial calibration we were easily able to start the car for fine tuning. We did have to select a different MAP sensor on the menu to get the car to idle well but it was a piece of cake. |

We started our load dyno tuning by filling in the lower load cells, doing dyno pulls at low throttle angles, holding a constant throttle angle right at the TPS break point in the map until the engine would hit a constant speed or the rev limiter. We watched the AFR to make sure that the engine would not drift lean or rich in the O2 sensor correction percentage. We also listened for detonation starting at 12.5% load. To aid this we data logged RPM, TPS, MAP, AFR, 02 correction, O2 feedback %, O2 target, coolant temp, air temp and battery voltage.

If we needed to adjust the fuel map we used this handy equation;

% change to fuel map=((O2#1 AFR- 02 target AFR)*10)+ O2#1 feedback value.

You can write a macro in AEM log to make this really easy. This equation will get your fuel map at each break point to plus or minus 5% AFR or closer even if your O2 correction is as high as 50%. This equation works with any fuel management system as long as you are using AFR for gasoline. If using Lambda or equivalence ratios you will have to do some units correction.

We continued this process across the map. You can skip every other break point and interpolate across to save time. You can also do this for points in the map that you don’t reach in normal driving. Once you get all the way across the map, its time to do ignition timing.

|

| Technosquare’s Superflow Dyno is a mixed load plus inertial type, making it good for tuning. |

1 comment

Hi I am looking for a pcm (ecu ) that will run my ls1 motor ,,,it’s in a gt40 kit car…the motor is approximately year 2001 asa ls1 fitted with speedmaster eight stack throttle bodies…has a delphi pcm…however I am have very low vacuum so will require a pcm that can overcome the low vac imput perhaps a alpha n type may work….regards Ken