Are Burns' Bends Really Better?

“It takes less time to do it right, than it does to explain why you did it wrong.” – Henry W. Longfellow

We are often times asked why our stainless mandrel bends and tubing is expensive compared with our competition. There are several reasons including the fact that we use US-sourced ASTM certified tubing (in some rare cases we may use a Canadian or Japanese sourced product based on availability) and that we use the utmost care in the mandrel bending process. As you know, mandrel bending is a process where metal tubing is bent around a die on a hydraulic or electric machine using a “mandrel” that is pulled through the inside of the tube in order to keep the tube cross-section round through the bend. There are many variables in the bending process that must be carefully balanced and monitored in order to attain a bend that has a round cross-section and no wrinkles, especially when bending thin-walled stainless tubing. These include mandrel tool material and condition, placement of the mandrel at initiation of the bend, machine pressure settings and wiper-die rake to name a few.

To assure that these parameters do not drift out of tolerance requires an alert operator on sophisticated benders, both of which are costly for us – but more importantly, saves you time and money in the long run.

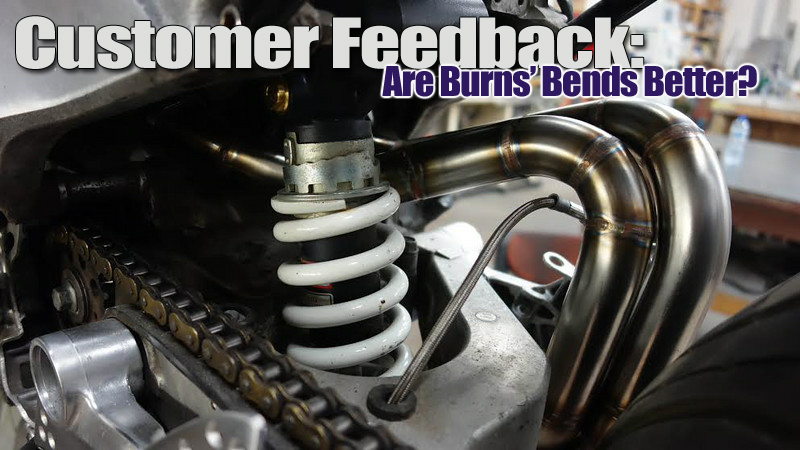

Below is an experience from a customer named Dan Yoder who was building an exhaust for his Honda V4:

“So I started on a bike exhaust and got some bends from Company X because a friend of mine is good buddies with them. After spending about $500 and oh I'd say 25hrs of my time I got the first bank of parts mocked up…wasn’t paying too much attention to the fit of each section, more about mocking the path of the exhaust. Then I get closer to tack welding and notice how “ovaled” the bends are.

This is a V4 bike so the exhaust snakes all over hell and there are several sections where I took a 180 bend and quartered it because that's really the only way to make it work. Needless to say I was not happy with how the fit was when you turn the cut around on itself. There are actual air gaps on either side. I heard from a good friend and chopper builder that he only uses you guys and that I likely bought sh!%%y bends.

Below are some pics that show each opposing side of the fit up (couldn't get an accurate shot from one pic). If I were to re order my material from you guys can I expect a better fit up at the peaks of the bends? What I’m working with now will not only look sub-par when it is done but it will take forever to get each section formed right for welding….and lets not even talk about how much of a PITA welding those parts would be.”

What Dan is describing is a bend that is ovalized through the bend section. Even though a mandrel has been pulled through the tube during the Honda V4 Side bending process, one of the bending variables was not properly adjusted and the bend ended up with an oval cross section. Not only does the bend lose cross sectional area (i.e. less flow capacity) but when the bends are cut and mated, the ovals do not match up, creating large air gaps which are evil in the world of stainless steel welding. The fabricator is left with a couple of options: 1. He can get a hammer and vise out and spend hours trying to form each bend to round again, or 2. He can quit while he is ahead and get some decent bends. Dan wisely chose the latter.

Recommended by a buddy of his, Dan contacted Burns Stainless to discuss his predicament.

“I asked if anyone was available to talk to about the tolerances of your bends and before Jack got on the phone he had already pulled my order and measured my parts….that’s great service right there!” What Dan learned then surprised him, “We found the worst bend from Burns was out of round by .01”, whereas the competitors was .1”…yes .1”, that's damn near an 1/8″!!”

Remember the adage “It takes less time to do it right, than it does to explain why you did it wrong.” We are fabricators too, and understand that in order to build a top quality product, one must start with top-quality products and skill. Not all customers and fabricators will appreciate the subtle qualities of our mandrel bends and tubing, and honestly, our products are not for them. But for customers like Dan who do appreciate quality, Burns Stainless is committed to provide them with the best stainless steel and aluminum products possible. We will not cut corners if it means compromising the quality of our products.

Now you sure couldn’t tell from the pictures that this was Dan’s first time to build an exhaust and weld stainless steel. See what you can do if you have the right stuff! Are you committed to doing the best job possible?

“I will be using Burns in the future for sure.” – Dan Yoder