Ask Sarah: What's Your Intake?

By Sarah Forst

Got a difficult tech question? Email Sarah at asksarah@motoiq.com

I'm debating going carbs or ITB's with EFI. What is the advantage to using carbs over EFI? How do ITB's perform over a single TB?

J.T.

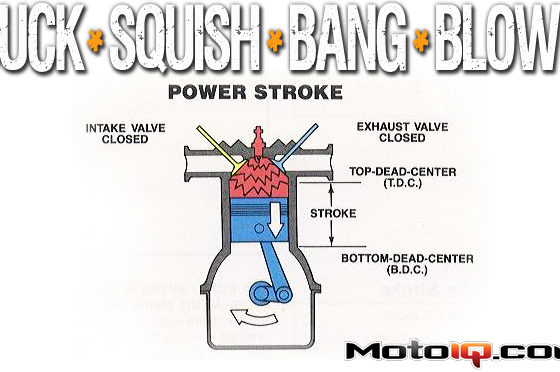

I love it- a question (and name) full of initials. Thanks for getting right to the point! Simply put, carbs are simple. Modern fuel injected cars use a throttle body and fuel injectors to control the proper air/fuel ratio. A throttle body uses a butterfly valve to regulate airflow into the intake manifold and combustion chamber. There can be a single throttle body or individual throttle bodies (ITB), which is a system using one throttle body per cylinder. A manifold absolute pressure (MAP) sensor or mass air flow (MAF) sensor is located in the intake to let the computer know how much air is flowing into the engine. Other sensors help the computer measure engine load, engine temperature, and calculate the required air/fuel ratio to control how much fuel- and when- is delivered by the injectors.

|

| Bisi Ezerioha discovered that carbs can make more power than EFI under certain conditions and are particularly well sorted for all motor drag racing. Bisi uses sidedraft Weber DCOE carburetors on his Drag Honda Insight. |

Carbs handle the job of both the throttle body and fuel injectors by delivering both air and fuel. The carb directs air through a venturi. The air pressure differential creates a suction which emulsifies the air with the fuel. An increase in air mass creates a greater pressure differential and supplies more fuel. Since it's an all in one package, it's usually a cheaper and more simplistic system to employ- no fancy electronics or sensors. This primitiveness is also its downfall.

Modifications to carbureted systems were necessary in order for the engines to comply with the stricter exhaust emission regulations passed in the 1970's and 1980's. Manufacturers started moving to fuel injection systems because it was easier to pass these regulations. Early fuel injection systems may have been less reliable than carbs because they are more complex systems and rely on many other components to function properly. There are fewer failure points on a carb system. But nowadays, OBDII monitoring basically spoon feeds a diagnosing tech feedback from all the sensors in order to pinpoint any issues. With modern reliable electronics, a wideband O2 sensor and proper fuel management system, EFI is now more reliable and adaptable than carbs ever were.

|

| A suck through carbed turbo system, the carb can function normally but the fuel distribution is pretty poor and it is difficult to eliminate bog on tip in. It is also hard to get a carb to fuel properly over such a wide operational range. Boosted operation requires a very large fuel flow, big needle and seat, big main jets. It is difficult to calibrate the low speed jetting on many domestic type carburetors. |

Carbs are a constant fuel situation. They can be dialed in for a small rpm and air density range and run less optimally at other engine speeds. This means if they're tuned for lots of power (more top end), they can be boggy and lose some low end torque. Though they are easier to tune (basically trial and error just changing the jet sizes and emulsion tubes), they require more tuning adjustments for changes in altitude or temperature or for different power goals.

|

| A blow through turbo system, this works for low boost levels and has better distribution, however if boost pressure is very high at all, the fuel won't flow into the engine as carbs work at low pressures. It is important to make sure the carbs float bowls are pressurized to boost pressure. The carb will still have some problems carburating cleanly across such a wide operating range. |

Modern day electronic fuel injection systems are able to quickly adapt to varying conditions automatically. When tuned properly, they can provide the right amount of fuel for the entire rpm range. This also helps with fuel efficiency and they'll idle more smoothly. Carbs on the other hand, require a sufficient supply of fuel for all conditions, meaning some cylinders may get too much fuel at some times (in order to supply enough fuel for all times), but fuel injection can adjust to provide proper air/fuel ratios in all conditions. It's like having somebody change the jetting and emulsion tubes continuously. Carbs can offer a lot of peak power but at the expense of the rest of the powerband. EFI systems are capable of high horsepower applications without sacrificing low to mid range torque or driveability.

|

| The 150 horsepower Chevy Corvair Spyder was one of the first production turbocharged cars. It used a draw through turbo setup and was known for its high operating temperatures leading to small oil leaks from failing o-rings. The oil would burn on the hot exhaust manifolds or occasionally generate a lot of smoke or a putrid oil smell. |

Carbs aren't exactly ideal in turbocharged applications either. On a blow through system, the turbo delivers the pressurized air to the carb and the carb goes “WTF?” because it doesn't know what to do with the pressure. Remember that a carb functions (provides fuel) due to a pressure drop across the venturi and will supply the fuel for that pressure drop regardless of the boost pressure. Without additional fuel enrichment, there could be a lean condition at higher boost pressures and issues with fuel flow. When blowing through carbs, you also don't want to leak the pressurized air/fuel mix so you should seal off the carb and pressurize the fuel bowls to equalize the boost pressure in order for the jets to deliver the proper amount of fuel.

|

| A pressurized box for a a carburetor with a blow though system, This works at higher boost pressures. |

On a draw through system (the simplest way to turbo a carbureted engine), the fuel and air are mixed together first before passing through the turbo. But you can't employ intercooling because if you draw this air/fuel mixture through, the fuel vapors (which are denser than air) can separate and become concentrated, possibly igniting if the engine backfires; flambé anyone? Water injection is the only option for cooling. Since the turbo also has to pump this heavier mixture, it won't be as efficient trying to increase pressure in an area where the carb has already created a pressure drop. Lower turbo efficiency translates to a hotter air/fuel mix- not helpful for making power.

Basically, carbs are cheaper and simpler to tune but fuel injection is more adaptable, more fuel efficient (depending on your driving habits and what driving conditions the carb is tuned for), better for forced induction, and provides more driveability throughout the entire powerband.