This power chart should obviously only be used as a guideline for turbo selection. Check back on BorgWarner's EFR site in the near future for an extremely in depth turbo sizing app. You forum nerds are going to have plenty to argue about when that's released.

Did you know that BorgWarner is currently the largest OEM turbocharger supplier in the world? The BW turbo brands also include BorgWarner, KKK (Kuhnle, Kopp & Kausch, not the cone heads), and Schwitzer. Despite being as big as they are, BW is planning the release of the Series EFR turbos designed specifically for the performance aftermarket and racing. For the past year, Brock (aka Brockstar) and his team of engineers and techs have been hard at work developing the EFR product line. This is extremely fast for a company the size of BW with very stringent design and manufacturing standards. BW isn't a 5 person shop that copies a Garrett compressor wheel, rescales it in CAM software so there's an infinite amount of trims available, hogs one out of aluminum bar stock on a CNC machine and then proceeds to stuff it into virtually any compressor housing without compressor or turbine mapping (let's not forget about giving these hogged out turbos nonsensical names while they were at it). BW products must go through extremely stringent OEM style durability testing and multiple validations before product release. So a complete line of turbochargers released in about a year is actually light speed for a company the size of BW.

Here's an EFR on a high temperature gas rig that constantly increases gases to 950 degrees C and then cools the gases to 200 degrees C. This is one of the tests performed for 175 hours to validate the turbine section's durability.

Here's a BW EFR being tested with a Cosworth 2.6L stroker EJ257B engine.

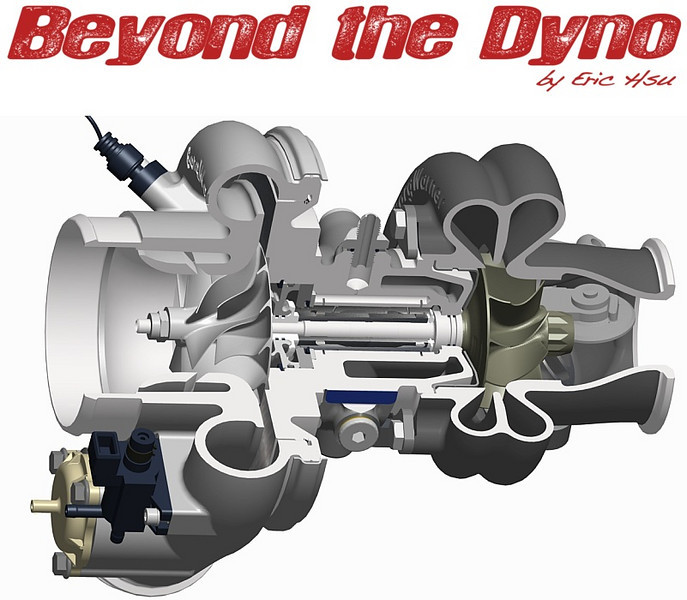

Cosworth was selected by BW as one of their pre-release testing partners to supply additional feedback, expanded real world application testing, and in the case of the Sierra Sierra EVO, a real world application in torturous conditions. With our ultra repeatable engine dyno test cells, small displacement high performance gasoline engine knowledge, and involvement with the Sierra Sierra EVO, the partnership just made sense. Perhaps Cosworth's involvement in high level motorsports and a potential Global Racing Engine release had something to do with it? Regardless, it was perfect timing for the Peformance Parts division of Cosworth since we were already starting to plan a line of high end turbo hardware and setup kits for the serious customer base. Whether on the engine dyno, in CAD, plugged into an engine simulation, or in the workshop physically test fitting the turbos on engines/cars, these past couple months at Cosworth in Torrance, the product development team has been working a lot with various prototype EFR turbos. As a result, Cosworth will be including BW EFR turbos in future “set up kits” and bolt on turbos. The set up kits will be targeted toward the medium/high power customer having his car built at a shop that can add the finishing touches such as fuel system, tuning, etc. The bolt ons will be using EFR centers, but with Cosworth designed turbine housings for direct fit applications. So far I'm very impressed with the hardware and the feature set. You'll be able to read a list of features anywhere, but I'm going to break down the features to you Beyond the Dyno style.

Here's a prototype EFR 7670 adapted to the factory EVO X exhaust manifold via adapter that maintains the advantage of twin scrolls. The adapter is also a prototype that we made at Cosworth in an attempt to test a potentially “reasonable” cost turbo upgrade. Optimizing gas flow is tricky with adapters, but the dyno tells all and the engine is scheduled to go back on the engine dyno in late December. If the adapter sucks then we will not be offering the adapter. In fact, it is unlikely that we will because we (as in Tyler and I) don't believe it will perform to our satisfaction. But I've been fooled by perception many times: THE DYNO TELLS ALL. The Cosworth engine dynos that is…

BTW, the EFR turbos are at the higher end of the aftermarket turbocharger price spectrum. The reason why is because they are so feature rich. The idea is that by using an EFR turbo, you'll end up saving some money at the end of the day by not having to purchase external items such as blow off valves, wastegate solenoids, wastegates, and paying for labor using difficult to work with turbochargers. As I wrote before, the EFR turbos are a clean sheet design specifically designed for flexibility during installation which is worth a bunch to the DIY enthusiast, tuning shop, or engine builder in itself. If you're a low buck turbo guy, you'll probably want to stop reading here. If you look for quality and don't mind spending a premium then keep reading.