,

Here's an EFR turbo on an NVH test rig to measure noise, vibration, and harshness (aka NVH).

Gamma-Ti Turbine Wheels

The heart of Series EFR's impressive feature set is the titanium-aluminide turbine wheels. BW claims that the EFR turbine wheels are nearly 50% lighter than the same sized wheel made from Inconel. What this means to you is superior transient response from the ultra low inertia and lower stress on the turbine shaft and bearing section which will result in longer turbo life. Have you ever revved an engine with an ultra light clutch and flywheel (e.g. Tilton carbon 7.5” twin plate) and noticed how it sounds almost like an F1 car? It's a similar deal here except when the turbo accelerates faster, air is compressed faster, and your turbo lag will be reduced. With such a low inertia, the turbine wheel will accelerate much quicker even with less exhaust gas energy. The downside to titanium-aluminide turbine wheels is that they are more brittle. Where an inconel or GMR turbine wheel will bend, the titanium-aluminide turbine wheel will probably chip. During BW's destructive testing it was discovered that there was zero loss in turbine wheel efficiency even when a couple of blades were missing.

Difficult and expensive to cast, but well worth the effort, EFR titanium-aluminide turbine wheels reduce inertia by over 50%.

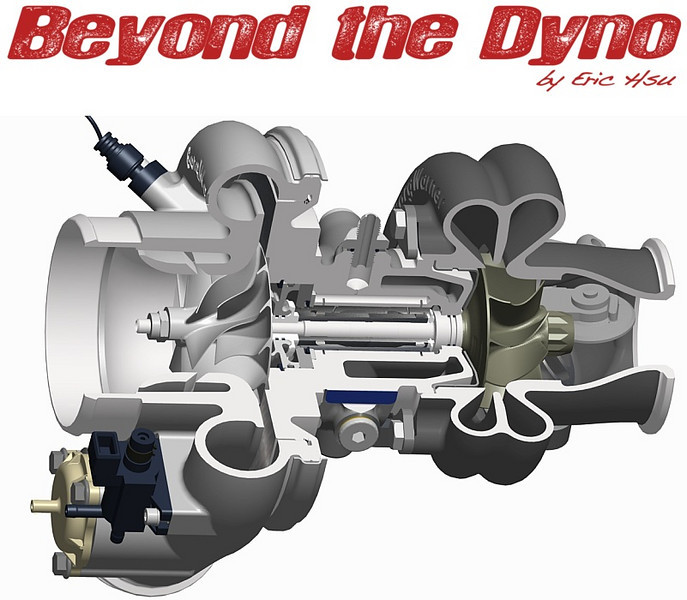

Investment Cast Stainless Steel Turbine Housings

Stainless steel of course offers superior corrosion resistance so there'll be no more rusty iron turbine housings. Another benefit of 300 series stainless steel is it's superior strength which allows a thinner wall casting. When I say “thinner”, I mean thinner for an OEM level manufacturer. Large turbo companies like Garrett, IHI, and BW actually test their turbos for burst containment. So when a turbine wheel explodes, the casting will contain the exploding turbine wheel rather than you getting a ninja star to your face. The investment cast surface quality gives the housing a much smoother cast surface which also benefits gas flow. The only downside to an investment cast stainless steel turbine housing is going to be cost, but if you want the best, you'll need to cough it up.

The investment cast housings provide smooth walls for gas to flow undisturbed. This increases flow and reduces backpressure which equals MORE POWER.

Super Buff Bearing Section

Brock and his team wanted the triple throw down, big power, no whammies, ultra strength bearing section. The dual row ceramic ball bearings and M50 metal cage offer a massive reduction in friction from a turbo with a thrust bearing. There are actually two sizes of Series EFR turbos, B1 and B2. The B1 turbos have a smaller bearing cage, but it is still substantially larger than their competitor's bearings. The B2 has the monster bearing section designed for extreme duty applications. The turbine and compressor sections are sealed with DUAL piston rings at BOTH ends to virtually eliminate oil leaking into either housing. The only downsides to all this trickness are cost and a longer physical length. As an example, a BW EFR8391 is 16mm longer than a GT40R. This probably isn't going to be a problem with a longitudinal engine configuration, but in a transverse application with A/C or power steering, this is going to make things a bit tight.

You didn't know that Brockstar was a hand model too, huh? On the bottom you have the most common ball bearing cage on the market today (brand G). On top in the EFR B2 bearing cage. Notice the dual piston ring grooves on both the turbine shaft and dynamic seal. Now there's a good chance your turbo won't get polluted blow by gasses even if your engine builder sucks.