To do a nice and sanitary installation, we used an ATI 370Z dual gauge pod. This allows you to install two gauges in the storage cubby up on the dashboard. The cubby has a door on it so the gauges can be hidden when not in use. The part numbers are ATI-VPOD-59-10 for the pod and ATI-52/60-CONV for the 52 mm adapter rings needed for the Innovate Motorsport gauges.

The VQ37VHR is throttled by both the VVEL variable valve timing system and the throttles. The majority of the throttling is done via the cam timing with the throttle remaining open for much of the time. This reduces pumping losses and improves fuel economy. However this means that most of the time, there is little manifold vacuum and this can cause crankcase pressure to build up. When this happens, the oil rings can become overpowered and the crankcase pressure will force oil past them causing smoke. This particularly happens when coasting down off throttle.

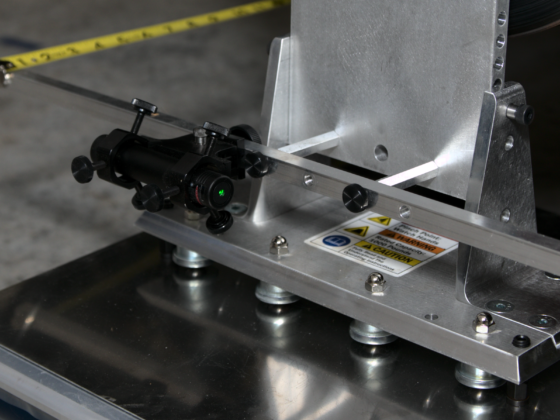

To solve this issue we drilled out the vent restrictor in one of the valve covers and vented the crank case through these Moroso check valves. The Moroso valves were used because they are sensitive to small fluctuations in pressure. They open when crankcase pressure becomes positive and close when there is intake manifold vacuum so as not to mess with the VVEL engines speed control. Removing the restriction and adding the check valves reduces crankcase pressure and smoking on overrun.

Here are the check valves installed on the engine. They go from the the valve cover vents through the check valves to the intake pipes before the throttles.

The sensor bolts to a bracket located on the shock tower. The supplied fuel lines bolt right in.

The included harness plugs in and goes to the chosen ECU input used by ECUTEK.

15 comments

This entire series was a real treat!! Feel free to put a dyno vid up on the motoiq youtube 🙂

What $/hp gain are we talking about here?

Around $200 per pony. It’s about $14k to replicate this engine build.

Seb tuned my car back in 2014 N/a and the same dyno I made more power and torque N/a on e85 than you did 371hp 291lbft. Except I had a stock rotating assembly and a dry sump. Recently had the car retuned and made 401hp after a switch to ecutek.

For us the owner didn’t want to go to long tube headers because he wanted backward compatibility with the stock exhaust system. He also didn’t want to spend more for a different air intake. Add the 5=10 more hp you get from dry sump and its right there.

I didn’t have long tubes either z1 shorties

That is pretty good, what sort of head work do you have?

Jun 272 cams and a better intake manifold

I’m saying that you spent 3-5k on a high comp motor that could have been used on an intake and an external oil pump to allow it to run past 8000 and been 20-hp higher. There isn’t a need to build these motors NA beyond cams. Only time it would be worth it is for a big displacement increase like Soho just did but even then they made like 3 more hp than my last retune at BTW.

I would have liked to run long tube headers and a different intake, but we can only do what a customer wants to do. To me a dry sump is pretty hard to integrate on a street car with AC and all, not to many customers will pop for that.

Excellent info and cool build! I was wondering why the Moroso check valves instead of a catch can for each bank? I assume the rest of the pcv system is kept as stock? I.e stock pcv valves still in place or the valve was drilled out? A little unclear as to how it was plumbed and why it was chosen over catch cans?

I’d like to know more about the PCV setup. What Moroso check valve part number was used?

With regards to the routing, the check valves are place inline with the rear port with the direction of the flow going from valvecover to intake pipe port. The front PCV valve is kept, along with the factory hose connecting to the front manifold vacuum ports. Is this correct?

I too would like any additional info on the check valve addition vs catch cans if possible.

Because the breather lines are actively part of the sealed crankcase and the VVEL system not being under throttle control and not being able to have an open breather. Routing them to a catch can would be a big vacuum leak and the RPM could run away.

I understand your reply but only see potential of a vacuum leak if you were venting the cans to atmosphere otherwise its still closed loop system. I think this was an initial misunderstanding on my part. I thought the check valves were initially inline with the pcv valve loops. Hence asking why cans were not put inline with the pcv valve loops Instead and doubling valves in the loop.

If I understand the plumbing it looks like those are the rear valvecover breathers crossed over to opposite banks intake with moroso valve inline. Does this balance pressure across banks vs stocks same side rear valve cover breather to same side intake? Looks like the actual pcv valve loops are left alone?