Nowadays as technology has enabled us to extract previously unheard of power levels out of our engines, the once rare failure of the ring and pinion gear in the differential is becoming more and more common. Ring and pinion breakage used to be something that just drag racers and drifters would experience but now as power levels rise, tires improve, more sophisticated aero generates huge levels of grip and dog shifted transmissions increase the shock load on the drivetrain, even road racing cars are starting to suffer from failure of the ring and pinion. To prevent failure, it can be an expensive endeavor to put a bigger and stronger differential in your car and a bigger diff usually has significant penalties in the weight and friction departments. So how can you improve the life of your ring and pinion? We did a few tricks and with some help from our friends at WPC Treatment, CTP Cryogenics and AFCO to do just that. Let us show you the stuff that we did that can more than double the life of your parts.

The Evasive Motorsports/Eneos Oil/Turn 14 Distribution Toyota 86 Pikes Peak car is a prime example of a car that can benefit from our gear treatment. With up to 1000 hp on tap, big slicks, moderate aero loading and a sequential transmission, the car puts a lot of stress on its drivetrain. Last year, the car ran in numerous test sessions and competed in Grid Life’s Time Attack at Road Atlanta. The car then ran for quite a bit of time in testing and practice at Pikes Peak and was running an excellent podium assured split time when the differential failed nearly within sight of the finish line. The diff failure negated a year long effort from the team, a promising finish and even a chance for a win.

For 2020 many options on improving the diff life were considered including going to a larger, Ford 8.8″ differential. However this would be a 30 lb weight penalty on an already heavy car and would need fabrication and a new, more expensive set of spares. This would represent an investment of over $5000 on an already tight budget (Pikes Peak is already a very expensive event to run). Since the OEM differential ran for several hours before failure it was decided to try to extend its life and start the final time trial up the mountain on an brand new assembly. Our gear prep could easily double the ring and pinions life and that should be more than adequate to assure finishing Pikes Peak and Super Lap Battle.

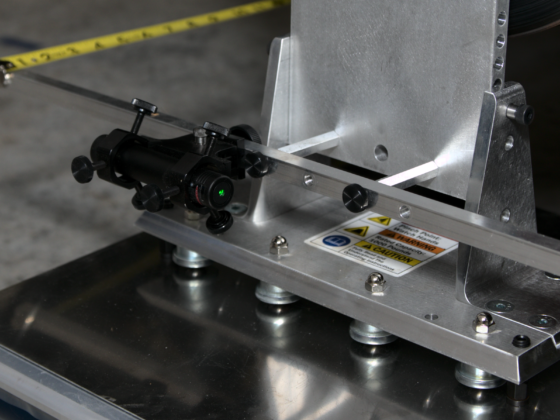

We started the gear prep by polishing the tops of the gear teeth with a scotchbrite pad on a drill to break all the sharp edges. We found that sharp edges left over from machining can dig into the gear faces and cause stress risers which can lead to failure. We did this on the ring gear and the pinion gear. Here is a close up of the pinion gear head showing the deburred edges on the gear teeth.

After detailing the ring and pinion, we sent them out to CTP Cryogenics to have them cryo treated. Cryo treating is an extension of the heat treating process which stress relives the parts and coverts the crystalline metal structure of the metal from a Face Centered Cubic Crystal structure called Austenite to the harder and stronger Body Centered Cubic structure Martensite. Cryo treating does this just as heat treating does but it further improves the conversion of Austenite to Martensite. This gives the metal a more homogeneous structure across its surface to the core and greatly improves, hardness, wear resistance, fatigue strength, and tensile strength.

8 comments

I have treated Internal Combustion engine and gear-train assemblies with Cryogenics for some 20 years now. Why? Because through decades of serious race testing and flogging…it WORKS!

All treatments are beneficial. However, surface treatments are exactly that, surface treatments. Cryogenics probes down into the metal beyond a components surface to realign the parts internal grain structure.

In 2000 I modified a Honda CR-500 (491.4 cc’s or 29.9 CID) . We increased its stock Torque output of 53.3 Lbs Feet to 100 Lbs Feet of torque at the rear wheel. The stock 5 speed gear box was not happy and soon exploded, gears, bent gear shafts and destroyed the engines left side case.

I had the gears, gear-shafts, shift forks and engine cases, cylinder and cylinder head all Cryogenically treated. We never had another problem. The engine is still together and operational today.

Don Redmon

Replika Maschinen, Inc

Instagram.com/replikad/

So staring down the barrel of doing stuff with a small quick change that needs a new ring and pinion… where would you slot ISF treatment in, in order of operation?

In the same order of operations as described in the article.

From what I’m seeing it looks like you went cryo, shotpeening, WPC – I was wondering if ISF finishing had a place in things since I’m more concerned with friction losses than strength.

One thing I noticed about ISF finishing is that it does change clearances a few thou even though they say it doesn’t. WPC is pretty good for friction reduction and helps by increasing fatigue strength as well.

I’ll reach out to the vendors you brought up for a quote once I have my replacement R&P in. Every little bit helps.

Definitely not drifting power capability, but I’m doing design work on fitting a Miata/S2k size LSD into the quick change I’m going to be running. Prototyping it with stock RX-7 LSD, but if that works no reason I can’t perform similar mods to an OS Giken diff.

Which quick change? OS and carbotech make drop in ones for Winters.

Speedway Mini Stock – SCCA GT3 class car so limited horsepower and I’ve got a really aggressive weight target. There’s the ICP Variloc that’s off the shelf if I can’t modify something to work, but I think the OS has some tuning options.