,

|

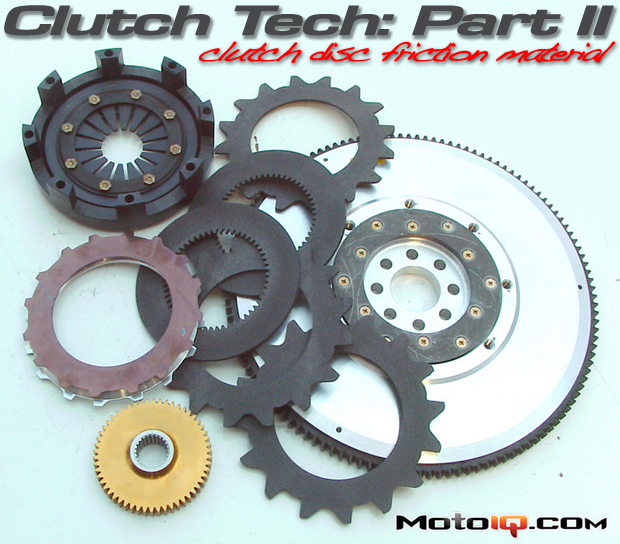

| Stock clutch discs usually use an organic disc material. This is literally cardboard reinforced with stands of Kevlar and fiberglass. Organic discs are known for their smoothness and low wear under stock conditions. For performance use, they rapidly glaze and wear. |

Friction Material

A typical stock disc’s friction material is designed for smooth operation. This is engineered for both driver comfort, ease of use (a smooth clutch is less likely to stall if you are lame at driving) and cushion to the drivetrain. The stock friction material is usually something called an organic material. Organic friction material is made of cellulose, usually reinforced with some heat resistant stuff like chopped fiberglass and mineral wool in a thermosetting phenolic (the heat resistant plastic they make pot handles out of) resin base. The cellulose is like cardboard (no kidding) and helps initial grip. The mineral wool and fiberglass strands provide burst strength, which is the friction material’s resistance to breaking up and falling apart, especially with shear and centrifugal load. They also help high temperature frictional properties.

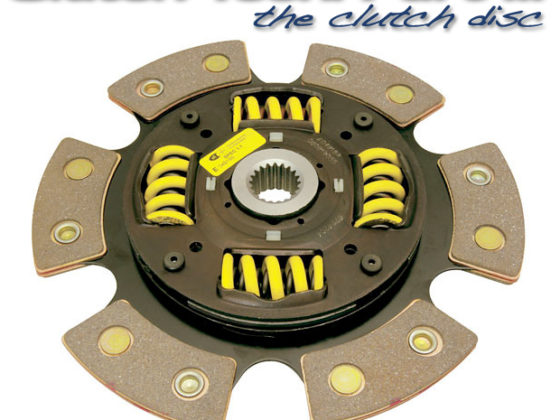

The friction material is typically bonded to the marcel spring of the disc with a high temperature adhesive and the marcel spring is riveted to the disc itself. We will explain what a marcel spring is a little later. On racing type discs, no Marcel is used and the friction material is bonded and riveted straight to the disc. This is adequate for most use but under abusive conditions the adhesive can shear off causing the friction material to delaminate from the disc. For this reason high performance clutches normally use a combination of bonding and rivets to clamp the friction material down.

In the bad old days, Organic discs used to have asbestos in them instead of cellulose which actually worked pretty well and made for strong, smooth and durable disks. Asbestos was superior as a friction material due to its high heat resistance, relatively high strength and high Mu (coefficient of friction – the higher the number, the better the grip and slip resistance) under high temperatures. Unfortunately asbestos is a powerful carcinogen and is now not allowed for automotive use. Once asbestos was banned it became very difficult for manufacturers to make a smooth engaging, long lasting, clutch disc.

With no asbestos, organic materials do not hold up to abuse very well but they do offer buttery smooth engagement. When pushed hard, the resins in the organic disc start to outgas, melt and form a slippery glaze that allows the clutch to slip. Under extreme abuse the resins and cellulose actually start to burn. Organic materials have very little mechanical strength and they tend to burst under high rpm and load.

|

| Unorthodox Racing makes a Kevlar disc with no Marcel and an unsprung hub. The Kevlar gives some degree of smoothness and the lack of hub springs and Marcel make for fast shifting. |

Heavy Duty (HD) and racing discs have friction material made of several different ingredients. A mild HD disc usually uses chopped Kevlar strands in a phenolic resin base. Kevlar is a space-age aramid (in the nylon family) fiber that is six times stronger than steel in tension and is fairly heat resistant. Kevlar is the same stuff that bullet proof vests are made of. Kevlar offers good burst strength and good wearing characteristics but has relatively poor frictional gripping properties. This makes for smooth engagement characteristics but only average grip. Because of this Kevlar discs need lots of clamp pressure from the pressure plate to hold without slipping.

A Kevlar disc must be carefully broken in for 100 to 500 miles before it can be abused. The flywheel on a Kevlar disc must be meticulously resurfaced and no oil or grease can contaminate the disc, not even fingerprints. If all of this is done correctly a Kevlar disc can provide a very long service life because of it’s inherit toughness. Because it’s held together with phenolic resins, Kevlar, like organic material is prone to glazing from abuse. Once a Kevlar disc is glazed, it will most likely not recover and must be replaced. On the plus side, Kevlar is less abrasive and easy on the flywheel and pressure ring surfaces causing little wear of these parts, another plus if long life is important to you.

|

| This Kevlar disc with a sprung hub is as smooth as a stock disc even with no Marcel spring. |