Also involved with Cosworth Subaru engines and most other builds that occur in the Cosworth USA build shop, is Lyon. Lyon has been building engines umm….forever. We crack jokes about his age all the time. How long you ask? Well, he used to build Datsun 510 race engines when they were new! Lyon’s engine building experience comes from the different engines he’s built throughout the years at the various race engine building shops and teams. Those engines include the Datsun L20, twin turbo Chevy big blocks for boat racing, Porsche IMSA GTO and GTP engines for Andial, early Toyota IMSA GTU/GTO engines at Dan Gurney’s All American Racers, cylinder heads for the legendary Toyota 503E IMSA GTP engine at TRD, and of course the Cosworth CART/Champ Car and YDX Formula Atlantic engines.

Lyon also traveled back to the UK last year to assist in the build of protoypte F1 dyno mule engines due to the shortage of skilled builders at the head office. Today he builds primarily Mitsubishi 4B11, Duratecs, and YDX Formula Atlantic engines, but he will assist with oil pumps, inlet manifolds, Subaru engines, Mitsu 4G63, and cylinder heads on occasion. His borderline OCD-like obsession with perfection is what keeps everything coming out of the build shop top notch. Talking to Lyon is like talking to the encyclopedia of race engine building experience. I learn something from Lyon daily.

Here Lyon is inserting thrust washers in an EVO 9 4G63 short block build.

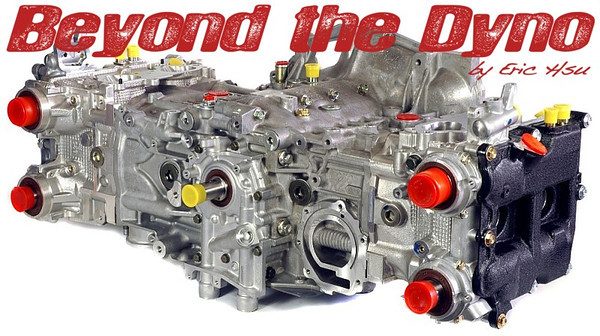

Where is engine #SB0400 going you might be asking? It’s home will be in the Cosworth “Red Dragon” 2008 STi. Inside the engine is a Cosworth billet 81mm crank, Cosworth 9.2:1 forged pistons, Cosworth forged rods, head gaskets, bearings, Cosworth 2008+ CNC ported cylinder heads, and of course the Cosworth Subaru dry sump system. This engine, like all of our engines, has the factory sleeves. We do not subscribe to the concept of pressed in iron sleeves in the EJ25 cylinder block for numerous reasons (different story for a different day).

The Cosworth “Red Dragon”.

Here’s engine #SB0400 on the engine dyno for break in and calibration. Tyler, Clayton, and myself (the engineering department) currently handle the dyno and calibration work at the moment.

Here’s a short clip of engine #SB0400 on the dyno during a power test. The test goes from 2000-8250 rpm. On the engine is a Borg Warner EFR 7670 @ 1.0 bar (gauge) of boost. The engine made 480bhp from 7250-8250 rpm on VP C12 fuel.

So for the most part, these are the three guys responsible for the Subaru engines and cylinder heads. There’s actually quite a few more people that are involved, but these three do the majority of the work and deserve the credit. Steve mentioned to me that we are 20 sets of heads short of 500 sets (1000 individual) cylinder heads too. I don’t think anybody at Cosworth, even Ken who started the Performance Parts business from the ground up, ever thought that they would build 400 Subaru engines and 1000 cylinder heads. From the number of engines that get delivered to the parts department, it appears that we’re selling more than ever and faster than ever too. I’m guessing that a lot of people are figuring out that with engines, quality is far more important than price. And you almost always get what you pay for when it comes to engines.

I’ll let you guys know soon when we hit 1000 Subaru engines and 2000 heads.

Subaru long blocks come shipped to your door in a ultra heavy duty blow molded crate.