,

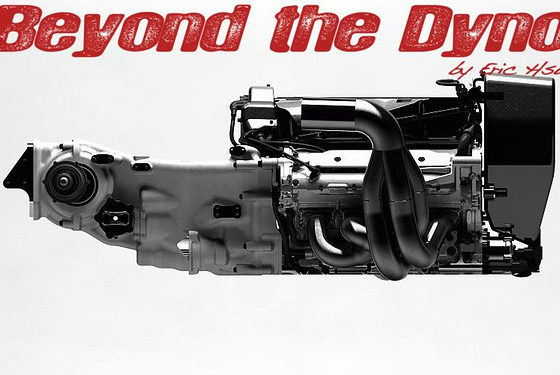

The extrude honing made good work of our lumpy and bumpy exhaust manifold. The stock exhaust manifold is a terrible design. Since it must hug the sides of the block to fit in the Z’s tight engine bay it has all sorts of flow impeding humps, bumps and twists as it snakes it’s way around bolts and other obstructions. Needless to say, the Extrude Honing really cleaned these parts up, increasing flow by an amazing 40%. Since this part of the car is awful to work on while the engine is in the car, we chose not to run headers for the added reliability of the cast iron manifolds. Extrude Honing was the only option to help out here.

|

| Valves in place in the head. The Swain coating protects the valves, combustion chamber and exhaust port. In a turbo motor this can really help things live. |

This motor was actually built many years ago and since then there are superior alternatives for exhaust manifolds. The best manifolds are made by Mike Smith and sold by Concept Z Performance. These cast manifolds are as durable as stock and are good for power gains of over 100 hp. No kidding, that’s how bad the stock exhaust manifolds are.

|

| The lower manifold is ported to match the intake ports. |

After these operations, we sent everything out to Swain Technologies for coating. We coated the combustion chambers, exhaust port and valve faces with thermo barrier coating. The exhaust manifolds, bottom of the intake manifold and turbine housings received White Lightning multi layer thermo coating. We finished the intake ports and back sides of the intake valves with Flow Coat, a hydrophobic fluid repelling and ultra slick coating designed to improve flow and eliminate deposit build up.

|

| The upper intake manifold is Extrude Honed. This increased flow by 20%. We coated the bottom of the manifold with thermo barrier coating because the intake manifold gets bombarded by a lot of heat soak in the notoriously hot 300ZX engine bay. |

Camshafts and Valvetrain

We opted for JWT’s turbo cams. JWT’s cams have increased duration and lift for improved high rpm power. JWT also grinds the cams with a minimum of overlap to reduce the chances of turbo backpressure induced reversion. Reversion is caused when the high backpressure created by the turbine’s of the turbochargers, which is more than the boost pressure at high boost levels and rpm, causes hot exhaust gasses to back flow through the engine on overlap (the point in the 4 stroke cycle where both the intake and exhaust valve are open). This back flow causes the internal heat of the engine to rise which promotes detonation which further increases heat. This can create a vicious cycle where the engine has a thermal runaway, overheating to destruction. Excess overlap also causes charge dilution at idle resulting in the lopey 8-stroking misfire race car type of rough idle.

4 comments

Question, what head gaskets are you using with the 89mm overbore?

It’s been so long ago but I think they were HKS.

why didnt you opt for solid lifters over hydraulic ones?

THey didnt have them at that time