,

JWT cams are computer modeled with the profiles designed to accelerate the opening of the valves at a rate that avoids exciting the valvetrain at high order harmonics. This helps the valvetrain passively resist spring surge and valve float without relying on super stiff valve springs. This is true camshaft engineering at its finest and something few companies are able to design to. Low spring rates reduce valvetrain frictional power loss and wear.

|

| I know its a bad picture but I had to steal a tiny picture off of JWT’s website. We changed the VTC springs for these stiffer ones that hold the VTC device in the retarded position more firmly to avoid an annoying rattle of the VTC mechanism at idle. |

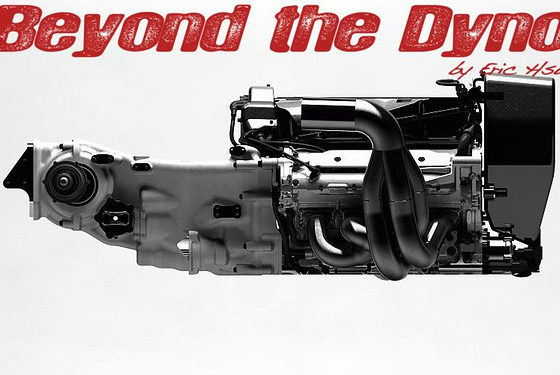

JWT cams are ground on new genuine Nissan billets so mismatched cam metallurgy with its accompanying excess wear is avoided. Since the cams are ground on new billets, the stock, factory base circle can be maintained so the hydraulic lash adjusters can still function well with no pump up worries. We settled on JWT’s big R5 grind which has more lift and duration than any VG30DETT cam on the market.

To reduce the chance of valve float at high rpm’s, JWT installed some of their dual performance valve springs to keep the valvetrain happy enabling us to bump the rev limit to 8000 rpm or about the limit of the hydraulic cam followers. The spring harmonics are matched to the cam’s profile for surge resistance. We also installed JWT’s heavy duty VTC springs. These are stiffer springs for the VTC variable cam timing system. This prevents a rattling noise from the VTC at idle caused by backlash in the system. The rattling noise is harmless but annoying and is worse when performance camshafts and valve springs are used.

|

| JWT R5 cams are the biggest cams avalible for the VG30DETT engine. They are good for 8000 rpm when used with JWT valve springs. |

That about sums up our progress so far. In following installments we will delve into turbochargers, more high performance engine coatings and the assembly process of our mighty motor. We also have some very trick parts like multiple map ecu’s, computer controlled Aquamist water injection, special head gaskets and many other parts to test, tune and tweek.

Stay tuned!

Sources

4 comments

Question, what head gaskets are you using with the 89mm overbore?

It’s been so long ago but I think they were HKS.

why didnt you opt for solid lifters over hydraulic ones?

THey didnt have them at that time