,

|

The low profile of the dry sump pan is shown here. The braided black hose is the external coolant bypass hose that max effort 4AG’s need to prevent overheating. |

To ensure a steady supply of air free oil, Technosquare relied on a Barnes 3 stage dry sump system with a modular pump featuring one pressure stage and two scavenge stages. The two scavenge stages suck windage from a TRD Formula Atlantic pan. The pan is an important element in improving the engine’s structure. Since the 4AG’s light weight block is not well suited for stressful high RPM and high power use, it is reinforced by the beefy pan. The pan was designed to be a structural part as the engine is a stressed member when it is installed into a Formula Atlantic race car chassis.

|

The bypass hose takes hot coolant from the back of the head to improve coolant flow in the head. This helps keep #4 cylinder from running too hot. |

The pan was built to greatly reinforce the wimpy 4AG block for this use and Technosquare used it to help keep the 4AG block from flexing. A TRD thick and strong Formula Atlantic valve cover was also used for this reason as the valve cover is also designed to strengthen the engine assembly in a Formula car chassis. These reinforcing parts should greatly increase the bearing and crank life as these were always marginal in the racing versions of the 4AG due to block flex at high rpm.

Oil pumped from the pan is cooled by a large Greddy oil cooler and de-aerated in a large Peterson tank. Peterson tanks are great because they are two- piece so they can easily be disassembled and thoroughly cleaned in the event of an engine failure.

|

The coolant bypass hose goes to the discharge of the water pump then to the radiator. You can also see the beefy strong casting of the TRD Formula Atlantic oil pan. |

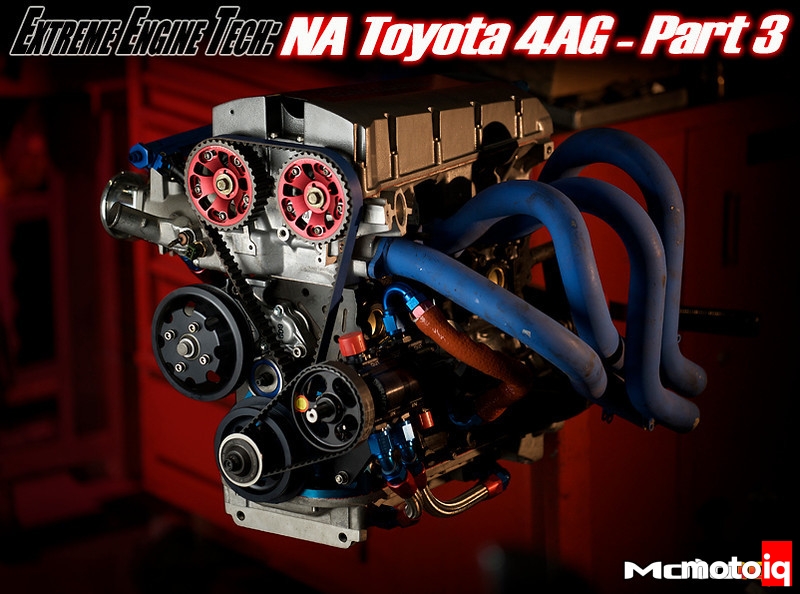

Induction is handled using a TWM intake manifold with huge 50mm TWM individual throttle bodies sporting short 40mm velocity stacks. A TWM fuel rail feeds 285cc Denso injectors. A vintage TRD FIA N-1 4 into 1 header handles exhaust duties. We feel that there is a lot more power to be found in this engine with a modern header design employing larger stepped primaries and a merged collector.

|

TWM 50mm ITB system has plenty of flow to support over 300hp. |

|

Fuel is fed to 285cc Denso Injectors through a TWM fuel rail with a TWM regulator. |