,

|

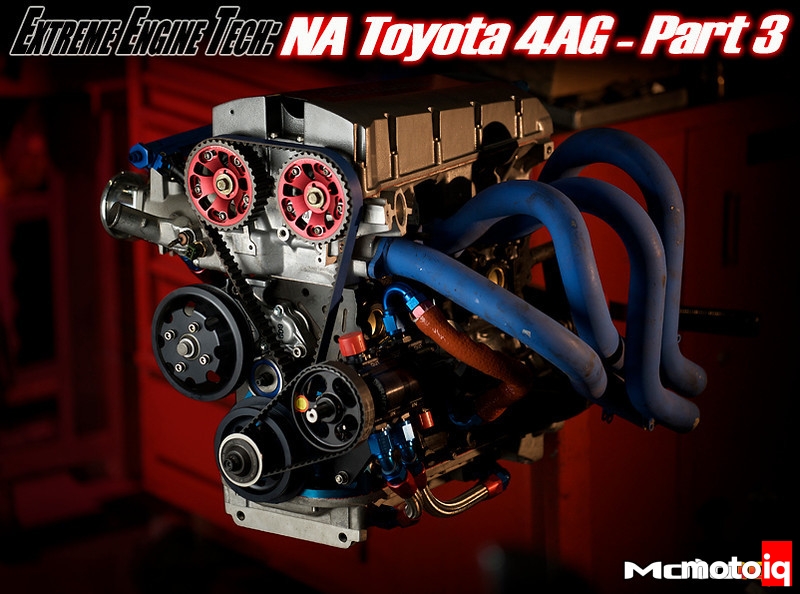

The TRD Formula Atlantic valve cover is very thick and strong which helps reinforce the weak 4AG block. This helps improve bearing and crank life. |

|

The Autronic ECU, CDI box and Wide band controller mount on the firewall inside the car. |

|

The CDI runs in individual coil mode and fires these coils from a Honda CBR Motorcycle, one per cylinder. |

Engine control is managed by an Autronic stand alone ECU and CDI system. The CDI fires Denso Iridium sparkplugs with an individual coil ignition system using Honda CBR coils acting directly on the plugs. Power transfer is handled by a twin disc OS Giken clutch and lightweight flywheel.

|

An OS Giken twin disc clutch and steel flywheel couple the engine to the transmission. |

In initial dyno testing the monster 4AG belted out 183 whp @ 8750 RPM with 122 lb/ft of torque at 6250 rpm on Technosquare’s notoriously conservative Superflow dyno. This would probably equate to around 200 whp on a Dynojet or 230+ at the crank. This is in line with the most developed 4AG’s ever built during the engine’s racing heyday in the Formula Atlantic era but with a wider powerband and more torque that the increased stroke gives.

|

The TRD FIA N1 4-1 header is more of a vintage racing piece. A modern header would probably be good for more power. |

We feel that there is potentially a lot more power to be found with development of this engine if Technosquare’s customer wants to find some budget to do so. A custom modern designed header should help considerably. Also the cylinder head was put together using well worn vintage TRD parts, especially the valves which were worn thin with a narrow margin and sunk deep into the valve seats. Newer modern valves and a correct valve job should free more power as well. WPC treatment could also help. We think that there is another 10-20 hp to be found here.

|

The lower line is the old 1600cc engine. The upper is the result of adding the stroker crank. |

Sources