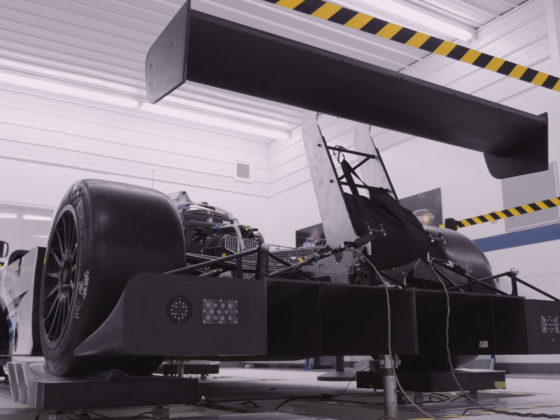

Clamp Plate Flexibility

Since the EFR compressors use a v-band to hold the compressor housing onto the backplate, there are no compressor housing clamps. While it gives the turbo a commercial diesel look, it does give the installer a super quick way to re-clock the compressor housing. On turbos that use clamp plates to hold the turbine housing to the center section, they’re almost always a bitch and a half to work on either because of water or oil fittings getting in the way or corrosion and bolt fatigue (in the case of a used turbo). Another ingenious feature of the BW EFR turbos are clamp plates that rotate out of the way. This makes life about 15000x easier in custom applications where you need to re-clock housings or need to service something regularly that requires turbo removal.

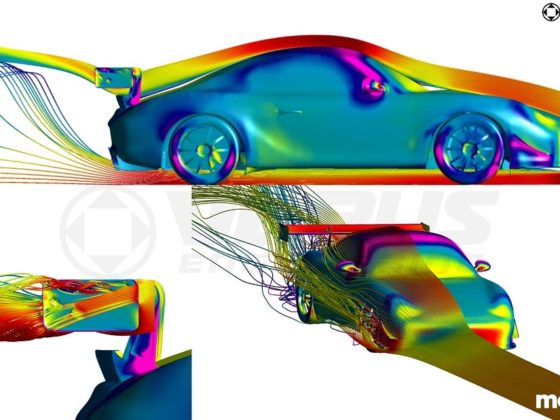

Aerodynamic Wheel Designs

EFR compressor and turbine wheels are designed using modern aerodynamics. Some of the wheels are similar to the BW Airwerks line of turbos, but all of the EFR compressor wheels are forged and milled. If you take a look at the compressor maps, don’t be surprised that you’re looking at a map of a compressor section with a compressor wheel that is substantially smaller than the competitors’. As an example, the EFR8391 turbo’s compressor wheel is capable of flowing 95lb/minute of air, but only has a 67.3mm inducer and a 91mm exducer. That’s actually pretty small for a compressor capable of such high flow.

There you have it, plenty of advanced features in one package! We will always be fans and users of the BorgWarner EFR Turbo for years to come, here is to another 10 years!