,

Selecting Headers

A well designed header can produce gains of 3-20 wheel horsepower, more on engines with aftermarket cams, supercharging or nitrous oxide injection. In addition to increased horsepower, headers can result in better gas mileage since headers improve pumping efficiency and scavenging.

A good general rule of thumb is that shorter and bigger diameter primary runners are better for top end power. Camshaft design is also a huge factor in header design. The later the closing point of the exhaust valve and the longer the cams duration, the shorter the header primary pipes must be. Longer and/or smaller diameter runners are better for lower rpm and stock cams. Again generally, the best header design for a naturally aspirated street car is a Tri-Y or 4 into 1 with long runners and/or small runner diameters, and a merged collector. Look for a header manufactured with thick wall, 14-16 gage steel tubing. Rust and heat-resistant ceramic-coated or stainless steel pipes will be more durable and longer lasting. Thick flanges will decrease the chance of exhaust leaks and last longer.

Headers and Emissions Controls

On post 1995 fuel injected engines, the ECU must receive a pre and post catalytic converter exhaust stream from the front and rear O2 sensors to avoid an SES “check engine” light. Removing the pre-cat or installing a cat-less aftermarket header causes the O2 sensors to read the same exhaust constitution and throw an error code. There are three ways to prevent a code from coming up. If you’ve only removed the pre-cat, weld a new bung behind the main cat and relocate the rear O2 sensor there. You can also use a rear O2 sensor simulator in line with the rear O2 sensor to fool the ECU into thinking the O2 sensor is actually sending the same signal as it would behind a cat, eliminating the “check engine” light. Finally, you can try using an anti-fouler plug adapter that locates the second O2 sensor away from the exhaust stream, although this often doesn’t work.

|

| This Nissan KA24DE header has provisions for O2 sensors and the EGR valve as well as Tri-Y construction and stepped primaries |

If you plan on passing an inspection, look for a header that will allow you to retain the stock emissions equipment. O2 sensors, EGR valves and other emissions controls do not rob wide-open throttle horsepower. Doing so won’t increase power and will only contribute to pollution. OBDII cars (1995+) will also throw an engine code if any of the emissions controls are not connected. These codes alone could keep you from registering your car or passing an emissions test in many states. However, if your header does not have a provision for the EGR, a disconnected EGR system will suck air and could create a lean air/fuel ratio at part throttle. To prevent this, you can disable the EGR system by disconnecting the vacuum line at the top of the EGR valve and plugging it, although you will probably want to swap back in the stock header for an inspection.

Most headers include provisions for the O2 sensor. However, a CARB EO number is the only thing many states will use to consider your header street legal even if you aren’t emitting excessive pollutants from your tailpipe. If you want to drive on the street without worrying about getting hassled by law enforcement or having problem registering or inspecting your car, invest in a header with a CARB number.

|

| We spotted these square tubed headers at the PRI show. Do they work? The owner of the company was pretty enthusiastic. We don’t know… |

Sources

5 comments

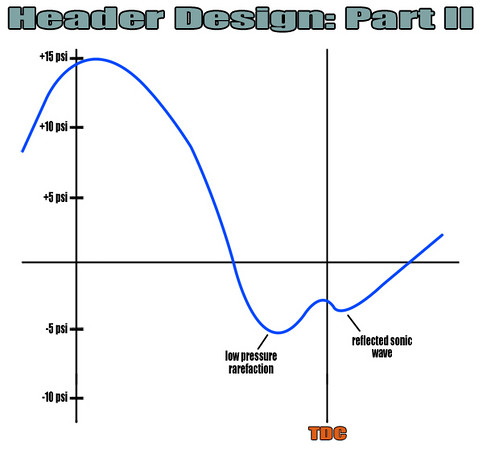

Good day… Is it safe to say that tuned\performance headers generate between 1-5PSI on an engine’s intake, once there is sufficient cam overlap? (what’s the correct figure) Thanks… =]

It does not generate any positive pressure on the intake, negative pressure in the header runner yes.

Not even with cam overlap?

No that’s more of a function of intake manifold design.

That’s not how headers work.