,

A used oil pump must be disassembled and inspected. The housing and gears should be inspected for scoring and if any is present with defects large enough to catch a fingernail dragged across the surface, the pump should be discarded. The oil pressure relief valve should be disassembled and inspected for debris and damage to the bore or piston. The piston must slide absolutely perfectly in the bore or problems may happen. Light scoring can be cleaned up with a ball hone but any deep scoring means the pump should be replaced.

|

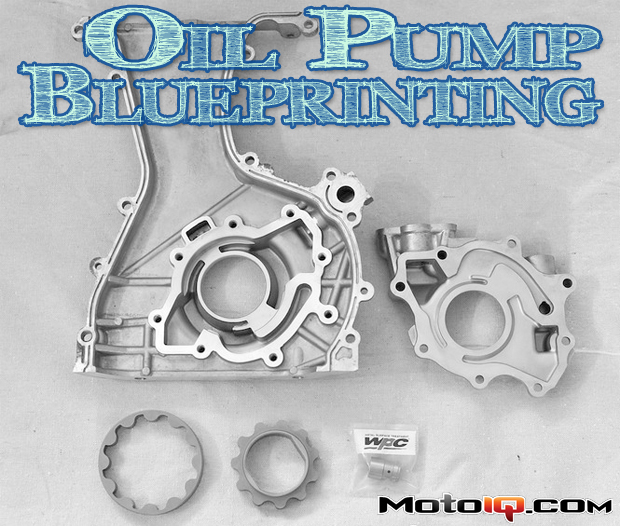

| This picture of the SR20VE oil pump shows the location of the inlet and outlet ports. On this oil pump the ports have a nice shape and radius. Other pumps may have sharp edges and rough castings that can be cleaned up. |

After inspection you should lightly deburr the gear rotors with scotchbrite red or with 400 grit wet dry sandpaper and solvent. You don’t want to round edges, just go over them and slightly break super sharp edges so you can’t cut your finger or risk scoring. Deburr your relief valve piston as well.

Next you might want to inspect your inlet and outlet ports in the rotor housing and put a light chamfer on the holes where they merge into the housing face. The chamfer should be no more than 1-2mm as you don’t want to change the port timing. Inspect the ports for casting flash and loose casting sand and remove them, perhaps by lightly porting the ports or polishing using a dremel or head porting bits and sanding rolls. Don’t make the ports bigger but clean them up. You might want to see how the ports in the pump housing line up with the oil passages in the block or pump pick up and do some port matching so there are no flow reducing steps in the oil flow path.

|

| Here is our SR20VE oil pump all cleaned up and deburred. It is hard to show this in a photo but it’s ready to be WPC treated. |

3 comments

What assembly lube do you recommend to use on the pump before putting it back together?

Engine oil works well.

Thank you.