,

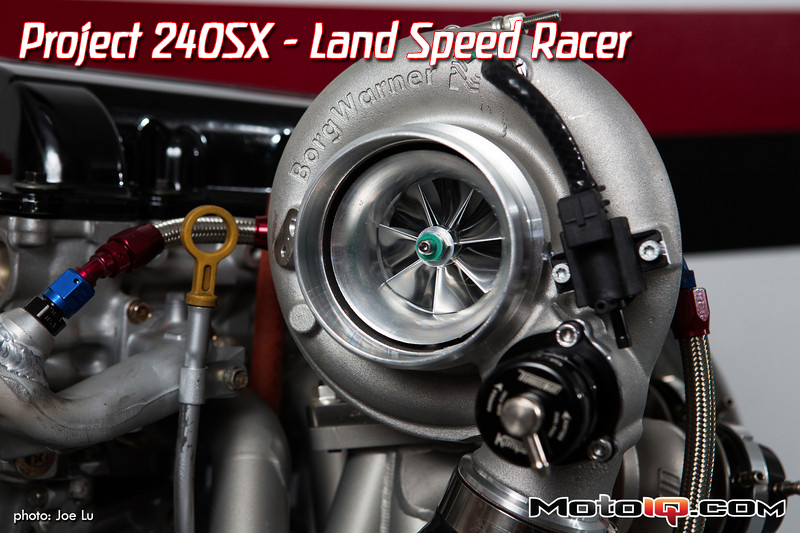

The compressor wheel is a “forged milled wheel.” During the forging process, an extruded aluminum bar is smashed into the general shape of the compressor wheel, optimally aligning the grain structure, and achieving far improved strength over a casting. The exotic, CFD birthed contours of the compressor wheel are then milled into the forging by a multi-axis CNC mill.

Disconnect the V-band clamp that holds on the compressor housing and take a closer look but please don't drool on my fender. The compressor wheel of the EFR 8374 turbo could be mistaken for a work of art and could easily look at home as some blang-blang around Floyd Mayweather's neck.

Disconnect the V-band clamp that holds on the compressor housing and take a closer look but please don't drool on my fender. The compressor wheel of the EFR 8374 turbo could be mistaken for a work of art and could easily look at home as some blang-blang around Floyd Mayweather's neck.

The center housing features four coolant ports. The four ports provide more flexibility in packaging the turbo inside the engine compartment.

The idea here is to configure the coolant lines in a manner to prevent an air pocket from forming inside the cooling passageways of the center housing. Asides from this feature, the center housing of the EFR 8374 turbo might seem rather unassuming.

Inside though, the technologically packed theme continues with the ball bearing assembly. The races of the ball bearing assembly are constructed from an M50 military grade steel while the ceramic ball bearings are encased in a silver coated metal cage to prevent galling.

In comparison, many other turbos will use a plastic cage with steel ball bearings. Note the redundant radial oil seals on the turbine wheel side of the shaft. No more oil coated turbine wheels!

On the turbine housing side, the EFR 8374 ascends to a whole new level of awesomeness. The housing itself is constructed from cast stainless steel, which with its low thermal conductivity, helps retain heat energy inside the gas stream. In fact, the overwhelming theme of the EFR 8374 series turbine housing revolves around optimizing exhaust flow efficiency to improve overall turbo response.