,

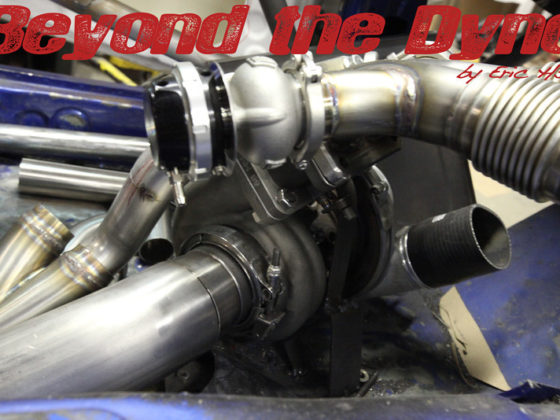

I figure all of these mods will come in handly when we finish the build of our race engine and we are pouring 30 plus pounds of boost down the SR20's throat like a College frat house armed with a pressurized beer bong contraption.

As a finishing touch, we swapped out the factory rubber radiator hoses for durable silicone replacements from HPS Performance Silicon Hoses. The HPS radiator hoses are formed to shape and connect the swapped SR20DET perfectly with the Koyo N-Flow radiator. By the way, the Koyo N-Flow radiator with its triple-pass configuration, is by far the best radiator I've used for curbing the SR20's cursed over-heating problems.

Unfortunately, the Greddy front mount intercooler and custom intercooler piping originally fabricated by Brian Kono at After Hours Automotive, were all damaged in the accident which is preventing Project 240 LSR from running at this moment. Instead of attempting a rather futile repair, we plan to run a Turbonetics Spearco air-to-liquid intercooler and construct completely new intercooler piping.

The Spearco air-to-liquid intercooler will help us achieve a dense intake charge of sub-ambient temperatures to offset Bonneville Speedway’s less than ideal altitude and weather conditions. Once the new system is complete, I’ll cover the the Spearco air-to-water intercooler in more depth as it will be an integral part of Project 240 LSR’s record breaking engine.

With less than two months until Speed Week, our Project Land Speed Racer is now equipped with a proven power train that we’ll be using for chassis development. In the meantime, we’ll be wrapping up the finishing touches on Project 240 LSR’s suspension with some Whiteline sway bars and also sourcing the necessary parts to complete the build of its race engine. Stay tuned.

Sources: