Above is a list of parameters Alex wanted data logged. The Wastegate Duty at the time wasn’t logging currently, but COBB has since updated the firmware and Wastegate Duty Base (%) is the correct parameter. One parameter that’s not logging correctly yet is exhaust gas temperature.

Above is a list of parameters Alex wanted data logged. The Wastegate Duty at the time wasn’t logging currently, but COBB has since updated the firmware and Wastegate Duty Base (%) is the correct parameter. One parameter that’s not logging correctly yet is exhaust gas temperature.

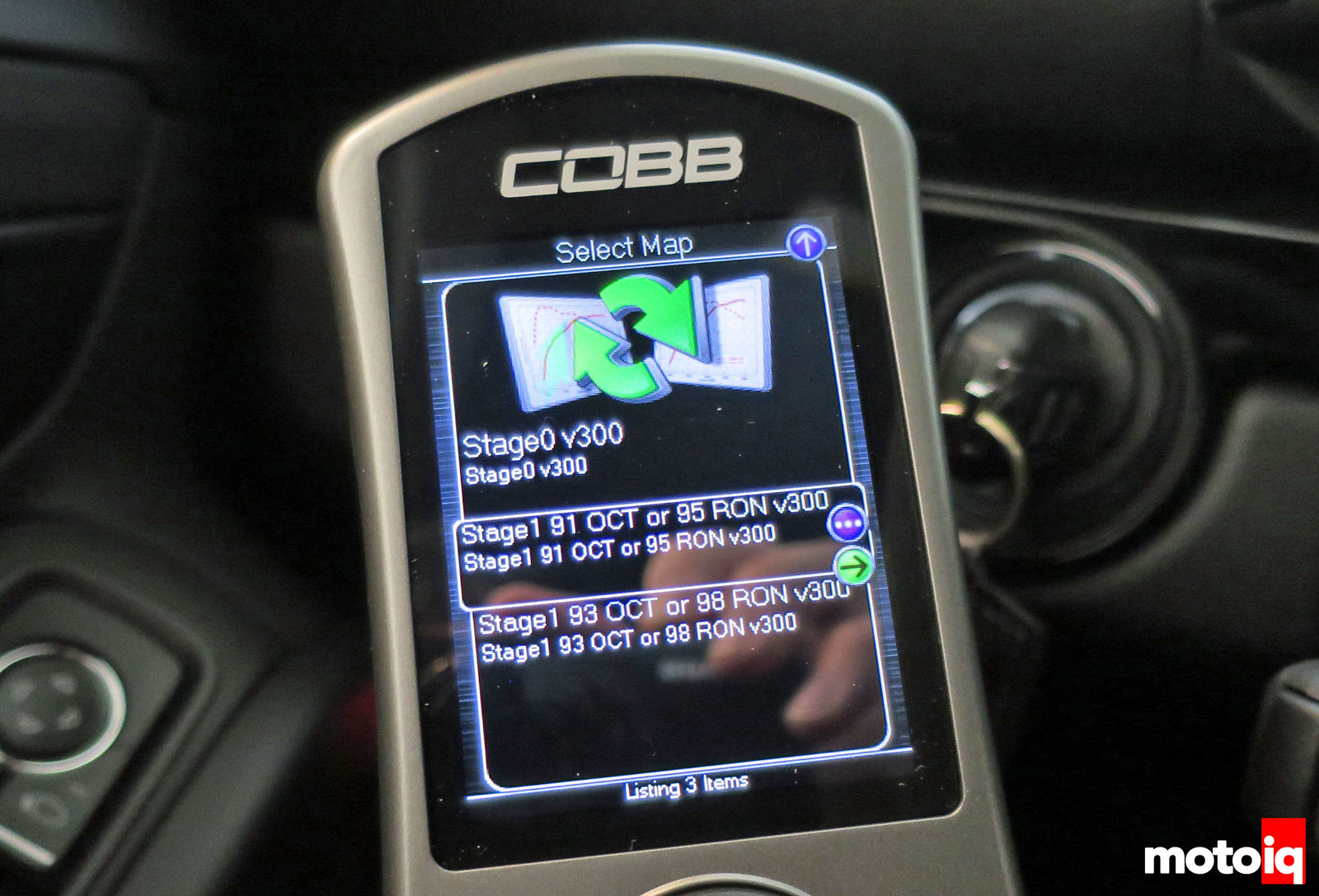

The COBB Accessport comes preloaded with three maps: Stage 0 which is a simulated stock map and the off-the-shelf 91 octane and 93 octane maps with the CARB EO numbers. Modern Porsche ECU control strategy is to try to hit a constant torque under all conditions. With the electronic throttle plate decoupled from the throttle pedal, the throttle pedal is a torque demand pedal. On top of that, the Driver Requested Torque value is not directly coupled to the throttle pedal position. In the graph above, I had the pedal flat to the floor the whole time, but you can see the Driver Requested Torque is moving up and down. Depending on Driver Requested Torque, environmental conditions, fuel quality, and who knows what else, the ECU creates a Torque Set Point. Then it tries to hit that set point and it calculates a Torque Actual value. At around 5500rpm, the ECU pulled some timing on Cylinder 1 and there was a corresponding drop in the Torque Actual. I would add, the torque value in the ECU doesn’t match what Porsche says is the torque rating of the engine. So, we can’t assume the reported torque value in the ECU is the actual torque value at the crank.

The COBB Accessport comes preloaded with three maps: Stage 0 which is a simulated stock map and the off-the-shelf 91 octane and 93 octane maps with the CARB EO numbers. Modern Porsche ECU control strategy is to try to hit a constant torque under all conditions. With the electronic throttle plate decoupled from the throttle pedal, the throttle pedal is a torque demand pedal. On top of that, the Driver Requested Torque value is not directly coupled to the throttle pedal position. In the graph above, I had the pedal flat to the floor the whole time, but you can see the Driver Requested Torque is moving up and down. Depending on Driver Requested Torque, environmental conditions, fuel quality, and who knows what else, the ECU creates a Torque Set Point. Then it tries to hit that set point and it calculates a Torque Actual value. At around 5500rpm, the ECU pulled some timing on Cylinder 1 and there was a corresponding drop in the Torque Actual. I would add, the torque value in the ECU doesn’t match what Porsche says is the torque rating of the engine. So, we can’t assume the reported torque value in the ECU is the actual torque value at the crank.

I did second gear pulls because the gearing is so tall; second gear in the 718 is about the same as third gear in the S2000. This graph shows a pull on the off-the-shelf 91 octane map with my 93 octane fuel cocktail. Again, my foot was flat to the floor the whole time, but you can see the dips in the Driver Requested Torque curve. For whatever reason, the Torque Set Point had some weird humps too and I could feel those changes in rate of acceleration during the pull. The big difference between this 91 octane OTS map and the ‘base’ map is the torque past 6000rpm with the OTS map making a good chunk more. Even though I had my 93 octane mix in the gas tank, there was still some minor knock on multiple cylinders during the turbo spool-up phase at low engine rpms.

I did second gear pulls because the gearing is so tall; second gear in the 718 is about the same as third gear in the S2000. This graph shows a pull on the off-the-shelf 91 octane map with my 93 octane fuel cocktail. Again, my foot was flat to the floor the whole time, but you can see the dips in the Driver Requested Torque curve. For whatever reason, the Torque Set Point had some weird humps too and I could feel those changes in rate of acceleration during the pull. The big difference between this 91 octane OTS map and the ‘base’ map is the torque past 6000rpm with the OTS map making a good chunk more. Even though I had my 93 octane mix in the gas tank, there was still some minor knock on multiple cylinders during the turbo spool-up phase at low engine rpms.

Enter Alex at Stratified Auto and a custom protune for my fuel mix. Maybe my custom X-pipe does a little something too. You’ll notice the Driver Requested Torque curve is much smoother now with resulting smoother Torque Set Point and Actual curves; I can feel it while driving. This was important for drivability during the track day at Streets of Willow. The improved drivability is a major reason I worked with Alex at Stratified Auto on the protune. And more power of course! Only one cylinder saw minor knock on this pull. You can see the Torque Actual closely follows the Torque Set Point because there was no timing being pulled in the upper rpm range. As for why the Torque Set Point doesn’t match the Driver Requested Torque, there’s probably some complicated Porsche algorithm looking at a bunch of parameters to figure that out.

Enter Alex at Stratified Auto and a custom protune for my fuel mix. Maybe my custom X-pipe does a little something too. You’ll notice the Driver Requested Torque curve is much smoother now with resulting smoother Torque Set Point and Actual curves; I can feel it while driving. This was important for drivability during the track day at Streets of Willow. The improved drivability is a major reason I worked with Alex at Stratified Auto on the protune. And more power of course! Only one cylinder saw minor knock on this pull. You can see the Torque Actual closely follows the Torque Set Point because there was no timing being pulled in the upper rpm range. As for why the Torque Set Point doesn’t match the Driver Requested Torque, there’s probably some complicated Porsche algorithm looking at a bunch of parameters to figure that out.

I used Virtual Dyno to track the performance changes in the different tunes doing pulls starting at around 2000rpm in the same location. You can ignore the difference in spool-up because I didn’t start each run exactly the same. The absolute values can’t be compared either because the weather conditions were different, the vehicle weight was slightly different due to varying fuel load, and a gust of wind could throw off the values. That all said, I tried to do the pulls in similar weather temperatures with minimal wind and similar fuel loads. You can see how the 91 octane OTS map makes more torque and power above 6000rpm compared to the Base map as we saw in the data logs. My custom map from Stratified Auto has more torque and power everywhere; I figure the car is at roughly 350hp and 330tq crank now, up from the stock 300hp and 280tq. Porsche states they limit torque to about 310-315tq for the stock clutch, so we’re just a little bit above what Porsche recommends. I had one data log with a partial fourth gear pull from Project S2000 that started at 3500rpm. Yeah, it was quick and I have some work to do get the T closer; especially considering the T weighs a couple hundred pounds more than the S2000. Below about 5000rpm, the T actually has a similar rate of acceleration to the S2000 because the power to weight ratio is similar. But above 5000rpm, the S2000 takes off being both lighter and having more power.

I used Virtual Dyno to track the performance changes in the different tunes doing pulls starting at around 2000rpm in the same location. You can ignore the difference in spool-up because I didn’t start each run exactly the same. The absolute values can’t be compared either because the weather conditions were different, the vehicle weight was slightly different due to varying fuel load, and a gust of wind could throw off the values. That all said, I tried to do the pulls in similar weather temperatures with minimal wind and similar fuel loads. You can see how the 91 octane OTS map makes more torque and power above 6000rpm compared to the Base map as we saw in the data logs. My custom map from Stratified Auto has more torque and power everywhere; I figure the car is at roughly 350hp and 330tq crank now, up from the stock 300hp and 280tq. Porsche states they limit torque to about 310-315tq for the stock clutch, so we’re just a little bit above what Porsche recommends. I had one data log with a partial fourth gear pull from Project S2000 that started at 3500rpm. Yeah, it was quick and I have some work to do get the T closer; especially considering the T weighs a couple hundred pounds more than the S2000. Below about 5000rpm, the T actually has a similar rate of acceleration to the S2000 because the power to weight ratio is similar. But above 5000rpm, the S2000 takes off being both lighter and having more power.

7 comments

If not going stiffer on the suspension, consider a DSC controller. Made a world of difference for brake dive. Also more comfortable on the street and can now use the sport suspension setting on my local mountain roads which were previously too bumpy. Still imperfect with high frequency bumps but better than stock. I tried to go the fairly minimal route and did camber plates and toe arms on my T.

Yup, DSC is already in the plans! The all-out plans would be Tractive coilovers with 80/100 spring rates. We shall see.

It’s incredible the amount of information that is required to properly modify a modern ECU; and also very impressive that Cobb has managed to design the Accessport to handle all of the communication / data with a user-friendly interface .

I’m really impressed with the power output information the ECU can provide. It seems like not too long ago it took a piggyback or standalone ECU to have access to that same level of information.

It’s hot in there! Maybe a GT4RS style intake is in order?

Thanks for your hard work, professional insights and for sharing all this.

I look forward to reading your updates as I too have a CT.

For a pure track car, I’d look to implement a GT4RS style window intake, but it’s a bit too radical and loud for street use for me. The T is really exceptional out of the box. The bigger brakes and extra cooling are strictly due to my car doing double duty as a track car. For street use, the stock intercooler system is *mostly* okay. I wish the cooling fans would kick on sooner to bring the temps down after the car has heat soaked after sitting after a drive. The IAT heat soak is really a sustained high power use issue at the track and not a problem on the street. Hmm, I’ll have to ask Alex if there’s a parameter on how to better control the fans for the air to water intercooler system. It’s my understanding the APR tune turns on the fans sooner or more frequently, but no information on the actual Porsche control strategy. If you are willing to tune your car, that’s the only mod I would say is a no-brainer for a street car. Everything else I’m doing to the car is tweaking to the nth degree but definitely not required.

Good morning!! I want to upgrade my 2017 FA20.

So far I have Cobb access port and full MAPerformance “bolt ons with a stage 2 off the shelf map. I want a pro-tune it’s just there is no reputable tuners within a 8 hour distance.

1. Map Cold air intake

2. Map Charge pipe

3. Map intercooler

4. Map high flow cat/J-pipe

5. ETS track edition cat back exhaust

6. Grimmspeed BPV

It runs good but I just know it has more to offer; I’m in the Philadelphia area? Thanks again

Lou

You can use Alex at Stratified like I do; I’m over a thousand miles away from him. You go drive, datalog, send the the logs to him, and he sends you back an updated calibration. I like getting data from real-world driving more than tuning on a dyno anyway. Nothing like the real thing where airflow and real world loading plays a role. The have plenty of tuning experience with the BRZ/FRS/GT86.