Speaking of doing a custom tune for local fuel and brand quality, I did one fill-up with Chevron gas at the corner down the street from me which caused significantly more knock than the Shell gas I had been using. It took adding about double the dosage of the race gas concentrate to get the knock levels down. This is California gas which will behave differently than gas in other regions of the country. California gas probably behaves a little differently between winter and summer gas mixes too.

The COBB Accessport can data log two parameters that are somehow used by the ECU to probably figure out the torque targets: intake pressure flow factor and exhaust pressure flow factor. As air mass flow goes up, the intake pressure flow factor value increases and the exhaust pressure flow factor decreases. The boost curve of my custom 93 octane tune holds boost until about 5000rpm at which it decreases. The compressor pressure ratio holds relatively steady at about 3.0 at near sea level. The pressure ratio is staying constant while the boost is dropping because there is an increase in pressure drop at the compressor inlet. Doing some quick math using a pressure ratio of 3.0, boost pressure of 19.0psi, and ambient pressure of 14.7psi results in a compressor inlet pressure of 11.2psi. So, there is a pressure drop of 3.5psi at the compressor inlet meaning there is lots of room for improvement.

The COBB Accessport can data log two parameters that are somehow used by the ECU to probably figure out the torque targets: intake pressure flow factor and exhaust pressure flow factor. As air mass flow goes up, the intake pressure flow factor value increases and the exhaust pressure flow factor decreases. The boost curve of my custom 93 octane tune holds boost until about 5000rpm at which it decreases. The compressor pressure ratio holds relatively steady at about 3.0 at near sea level. The pressure ratio is staying constant while the boost is dropping because there is an increase in pressure drop at the compressor inlet. Doing some quick math using a pressure ratio of 3.0, boost pressure of 19.0psi, and ambient pressure of 14.7psi results in a compressor inlet pressure of 11.2psi. So, there is a pressure drop of 3.5psi at the compressor inlet meaning there is lots of room for improvement.

There are pressure sensors in the intercooler before the throttle body, in the intake manifold after the throttle body, and one in the intake duct after the air filter and before the turbocharger compressor inlet. Using those values, the ECU can calculate the pressure ratio. There is no turbocharger speed sensor, so the ECU is likely estimating a turbocharger speed based on the pressure ratio and air mass flow because it knows the compressor map; it thinks the turbo is hitting about 178,024 rpm. The only info I can find on the compressor wheel size for the stock turbo has it at 46.5mm diameter inducer and 58mm diameter exducer which makes it a 64 trim. Assuming it’s based on the BorgWarner EFR6258 compressor wheel design which is a 61.4mm exducer and 65 trim which flows 44 lbs/min, the stock compressor wheel can flow about 38.7 lbs/min. BorgWarner shows a max tip speed of 540 m/s on the EFR6258 compressor map which would translate into a maximum speed of 177815 rpm for the stock turbo. I think it’s fair to say I’m near the limit of the stock turbo.

There are pressure sensors in the intercooler before the throttle body, in the intake manifold after the throttle body, and one in the intake duct after the air filter and before the turbocharger compressor inlet. Using those values, the ECU can calculate the pressure ratio. There is no turbocharger speed sensor, so the ECU is likely estimating a turbocharger speed based on the pressure ratio and air mass flow because it knows the compressor map; it thinks the turbo is hitting about 178,024 rpm. The only info I can find on the compressor wheel size for the stock turbo has it at 46.5mm diameter inducer and 58mm diameter exducer which makes it a 64 trim. Assuming it’s based on the BorgWarner EFR6258 compressor wheel design which is a 61.4mm exducer and 65 trim which flows 44 lbs/min, the stock compressor wheel can flow about 38.7 lbs/min. BorgWarner shows a max tip speed of 540 m/s on the EFR6258 compressor map which would translate into a maximum speed of 177815 rpm for the stock turbo. I think it’s fair to say I’m near the limit of the stock turbo.

I did take a drive up into the mountains to see what would happen to the boost level. As you can see, the ECU set a torque target of about 350 lb-ft and hit it. Check out the compressor pressure ratio hitting 3.6 compared to the 3.0 pressure ratio at sea level. The ambient air pressure at this point was 12.2psi which translates into being at an elevation of about 5000 feet. At this elevation, a naturally aspirated engine would be down in power about 17%. With the turbo engine, it increased the boost to maintain as much power as possible. This data point at 1356 seconds, I was at 5k rpms and hitting the 350 lb-ft of torque target. At sea level, it was making about 360 lb-ft, so the engine was only down about 3% in torque and power. Car manufacturers typically specific an elevation that a turbocharged engine must be able to maintain power up to as a performance target for the turbocharger supplier. Above that elevation, the power has to derate, or the turbocharger will spin itself up into oblivion. The turbocharger supplier has to specify a compressor wheel with extra pressure ratio capability in order to meet the power requirement up to the required elevation set by the car manufacturer. 5000ft is 1524m, so it looks like Porsche set the derate elevation at 1500m; 1000m-2000m are common targets. At this elevation 5000 feet, a 718 GT4 should only be making about 344hp and 256tq at the crank, so my T has about the same peak power but way more mid-range torque.

I did take a drive up into the mountains to see what would happen to the boost level. As you can see, the ECU set a torque target of about 350 lb-ft and hit it. Check out the compressor pressure ratio hitting 3.6 compared to the 3.0 pressure ratio at sea level. The ambient air pressure at this point was 12.2psi which translates into being at an elevation of about 5000 feet. At this elevation, a naturally aspirated engine would be down in power about 17%. With the turbo engine, it increased the boost to maintain as much power as possible. This data point at 1356 seconds, I was at 5k rpms and hitting the 350 lb-ft of torque target. At sea level, it was making about 360 lb-ft, so the engine was only down about 3% in torque and power. Car manufacturers typically specific an elevation that a turbocharged engine must be able to maintain power up to as a performance target for the turbocharger supplier. Above that elevation, the power has to derate, or the turbocharger will spin itself up into oblivion. The turbocharger supplier has to specify a compressor wheel with extra pressure ratio capability in order to meet the power requirement up to the required elevation set by the car manufacturer. 5000ft is 1524m, so it looks like Porsche set the derate elevation at 1500m; 1000m-2000m are common targets. At this elevation 5000 feet, a 718 GT4 should only be making about 344hp and 256tq at the crank, so my T has about the same peak power but way more mid-range torque.

This plot shows the Dynamic Boost anti-lag system at work. I got off the throttle at the redline of 7500rpm engine speed and hit the brakes. You can see the boost pressure spike for an instant until the blow-off valve can do its thing and relieve pressure. However, the pressure only drops to about 10psi and actually goes back up a bit at 14psi. I am completely off the gas pedal and actually on the brakes while the revs are dropping and the boost saying positive.

This plot shows the Dynamic Boost anti-lag system at work. I got off the throttle at the redline of 7500rpm engine speed and hit the brakes. You can see the boost pressure spike for an instant until the blow-off valve can do its thing and relieve pressure. However, the pressure only drops to about 10psi and actually goes back up a bit at 14psi. I am completely off the gas pedal and actually on the brakes while the revs are dropping and the boost saying positive.

7 comments

If not going stiffer on the suspension, consider a DSC controller. Made a world of difference for brake dive. Also more comfortable on the street and can now use the sport suspension setting on my local mountain roads which were previously too bumpy. Still imperfect with high frequency bumps but better than stock. I tried to go the fairly minimal route and did camber plates and toe arms on my T.

Yup, DSC is already in the plans! The all-out plans would be Tractive coilovers with 80/100 spring rates. We shall see.

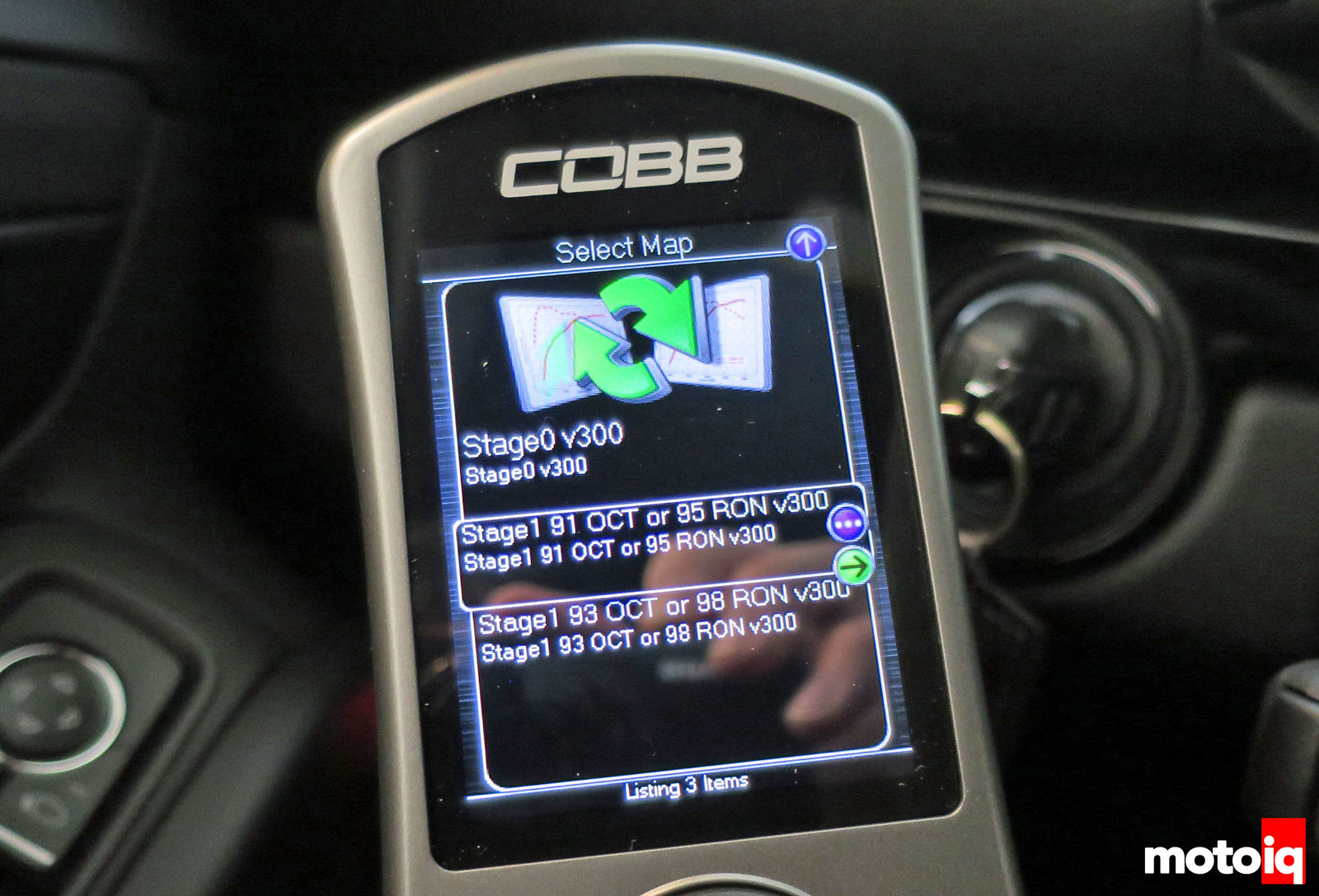

It’s incredible the amount of information that is required to properly modify a modern ECU; and also very impressive that Cobb has managed to design the Accessport to handle all of the communication / data with a user-friendly interface .

I’m really impressed with the power output information the ECU can provide. It seems like not too long ago it took a piggyback or standalone ECU to have access to that same level of information.

It’s hot in there! Maybe a GT4RS style intake is in order?

Thanks for your hard work, professional insights and for sharing all this.

I look forward to reading your updates as I too have a CT.

For a pure track car, I’d look to implement a GT4RS style window intake, but it’s a bit too radical and loud for street use for me. The T is really exceptional out of the box. The bigger brakes and extra cooling are strictly due to my car doing double duty as a track car. For street use, the stock intercooler system is *mostly* okay. I wish the cooling fans would kick on sooner to bring the temps down after the car has heat soaked after sitting after a drive. The IAT heat soak is really a sustained high power use issue at the track and not a problem on the street. Hmm, I’ll have to ask Alex if there’s a parameter on how to better control the fans for the air to water intercooler system. It’s my understanding the APR tune turns on the fans sooner or more frequently, but no information on the actual Porsche control strategy. If you are willing to tune your car, that’s the only mod I would say is a no-brainer for a street car. Everything else I’m doing to the car is tweaking to the nth degree but definitely not required.

Good morning!! I want to upgrade my 2017 FA20.

So far I have Cobb access port and full MAPerformance “bolt ons with a stage 2 off the shelf map. I want a pro-tune it’s just there is no reputable tuners within a 8 hour distance.

1. Map Cold air intake

2. Map Charge pipe

3. Map intercooler

4. Map high flow cat/J-pipe

5. ETS track edition cat back exhaust

6. Grimmspeed BPV

It runs good but I just know it has more to offer; I’m in the Philadelphia area? Thanks again

Lou

You can use Alex at Stratified like I do; I’m over a thousand miles away from him. You go drive, datalog, send the the logs to him, and he sends you back an updated calibration. I like getting data from real-world driving more than tuning on a dyno anyway. Nothing like the real thing where airflow and real world loading plays a role. The have plenty of tuning experience with the BRZ/FRS/GT86.