,

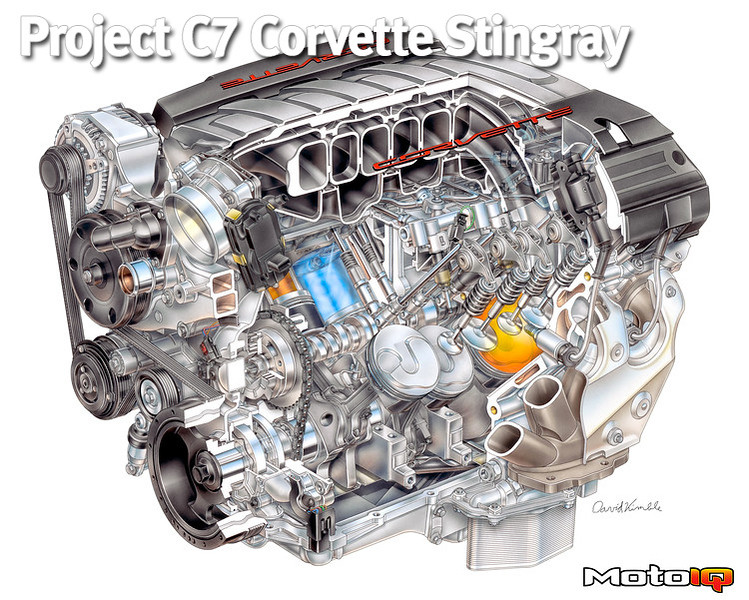

The compression rings are low-tension, thin and chrome faced to reduce friction to a minimum while still providing a long service life. The oil ring is also thin and low tension as well.

The cracked cap forged from powdered metal rods have been the subject of intense computer modeling to pair weight from them without sacrificing strength. The powdered metal means that all of the alloying agents are ground into a fine powder that is pressed into rough shape then forged into its final shape. This method assures that there are fewer strength reducing inclusions within the rod and all of the alloying agents are fully and evenly dispersed throughout the metal.

The block is cast from 391 aluminum alloy. The LT1 block is different from the LS in that it has cast in place of cylinder liners with an all aluminum deck surface. This gives a more accurate spacing of the bores and better head sealing. The liners are induction heated while they are being cast in place, so their position within the forming casting can be precisely controlled.

Each cylinder features a squirter that sprays oil on the bottom of the piston to cool it and also sprays on the cylinder walls to reduce wear and friction.

A high-pressure fuel pump is mechanically driven off of the cam and feeds the direct injectors that inject fuel at up to 2200 psi and 20cc per second. The high injection pressure is needed to overcome the cylinder's compression pressure. The injectors have multiple holes in their nozzles to atomize the fuel well for improved combustion. Comp cams is already producing fuel pump cam lobes that increase the injection volume for mods!