Even though our E39 M5 has been well maintained and is in excellent shape, it is still a 20-year-old car and some components were starting to show their age. In our car the radiator, as is common with most modern cars, started to develop some weeping where the plastic end tanks are crimped to the aluminum radiator core. Nearly all newer cars have this type of radiator construction and most will start to leak like this at 10-20 years of age as the seal between the tanks and the core starts to deteriorate. We decided to intervene before our seeping turned into a major leak and replaced the OEM radiator with a high-quality racing radiator from CSF Race.

The CSF radiator is designed as a bolt-in direct replacement part for the OEM BMW radiator. Even if you don’t need a performance radiator, as we stated in the intro, the OEM radiator has crimped-on plastic end tanks that are prone to leak. Especially with age, heat, and high pressures. The CSF radiator has fabricated tig welded aluminum end tanks that are furnace brazed to the core. This is a much stronger and more leak-proof construction method than the stock 3-piece radiator.

The CSF radiator has provisions for the factory vents and surge tank. The rectangular pockets on the bottom of the radiator’s end tanks go into the OEM rubber mounts on the core support for a perfect near-stock fit.

The CSF radiator has tig welded to the end tanks, leak-free, machined aluminum hose bibs for BMW’s proprietary click-in hose connectors, and provisions for the factory air guides and fan shrouds to make installation even easier. It also as provisions on the bottom to add-on a CSF Race oil cooler.

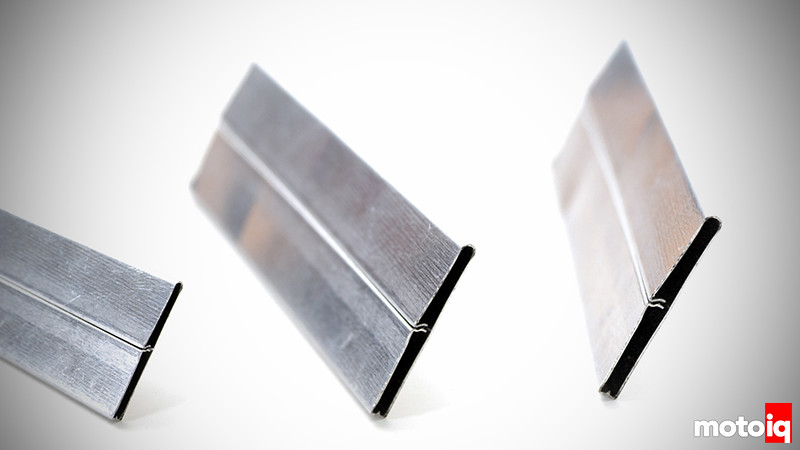

The internal construction of the CSF radiator’s core has some innovative features. One of these is the B-Fin tube. On a conventional radiator, there are rows of oval-shaped tubes. Factory radiators usually have two rows and aftermarket performance radiators have as many as 4. This gives more cooling area but the air has a problem penetrating the core and doing heat exchange, especially in the rearmost rows. The CSF core has one big tube in a single row. CSF calls this their B tube. The B Tube starts off as a sheet of aluminum that is folded back onto itself to form a B shape to the desired width. After forming, the seam of the tube is furnaced brazed to make it one piece and leak-free. The B-Tube gives the ideal ratio of fluid-to-air exposure with the center B pillar giving strength and an additional conduction path for heat to follow from the fluid to the outside of the tube. The internally smooth, one-piece construction also makes it easy for air to easily penetrate the core, greatly helping with heat exchange and cooling.

1 comment

That’s so rad – and cool.