A closeup of the rotating assembly shows our CNC lightened rotors, I-Rotary 2mm metallic apex seals, Atkins Rotary solid corner seals, and everything was WPC Treated and CTP Cryogenically treated, from the rotors, to the apex/side/corner seals, e-shaft, housings, and irons.

A closeup of the rotating assembly shows our CNC lightened rotors, I-Rotary 2mm metallic apex seals, Atkins Rotary solid corner seals, and everything was WPC Treated and CTP Cryogenically treated, from the rotors, to the apex/side/corner seals, e-shaft, housings, and irons.

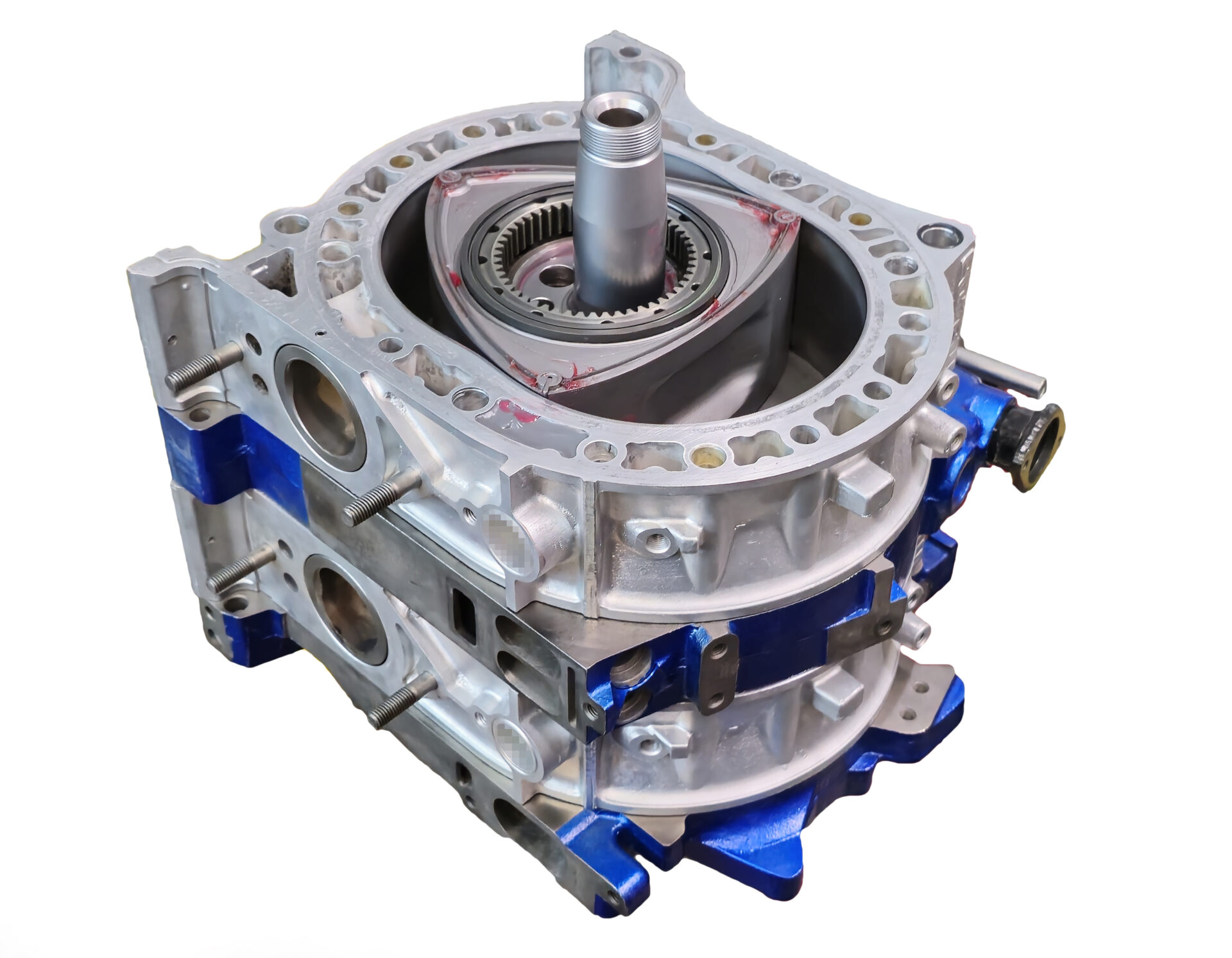

From above, we can see the epitrochoid shape of the rotor housings and the 4 additional dowl locations that Abel Ibarra added.

From above, we can see the epitrochoid shape of the rotor housings and the 4 additional dowl locations that Abel Ibarra added.

The geometry of the rotor housings and the interface of the rotors and apex seals is a truly impressive feat of engineering, precision, and simplicity.

The geometry of the rotor housings and the interface of the rotors and apex seals is a truly impressive feat of engineering, precision, and simplicity.

From this angle, we can clearly see all 6 dowels that now brace our 13B engine. We discussed in Part 13 the 4 additional dowl locations that our engine builder Abel Ibarra has come up with to stiffen and strengthen the engine block/stack after decades of trial and error, and success racing and setting world records with rotary engines.

From this angle, we can clearly see all 6 dowels that now brace our 13B engine. We discussed in Part 13 the 4 additional dowl locations that our engine builder Abel Ibarra has come up with to stiffen and strengthen the engine block/stack after decades of trial and error, and success racing and setting world records with rotary engines.

According to Abel, the stackable nature of the rotary engine causes the irons and housings to shift, distort, and flex; which leads to ovaling of the aluminum housings around the dowels, and is the main cause of rotor to iron contact (not from the rotor “wobbling” excessively on the e-shaft). Increasing the rigidity of the block with properly placed dowels is crucial to maintain the tolerances of the block during extreme use.

After installing the apex seal springs in the rear rotor, we bolted the rear iron in place with 4 factory bolts to hold the stack together before installing the studs.

After installing the apex seal springs in the rear rotor, we bolted the rear iron in place with 4 factory bolts to hold the stack together before installing the studs.

10 comments

Is the blurred out images of the port, really NSFW, or just a proprietary secret?

Otherwise, love the assembly porn!

It’s a bridgeport with a semi-peripheral port.

Lol I figured it must be some JDM mosaic NSFW material too.

Great documentation. Can’t wait to see further progress.

When researching components for my RX-8 engine rebuild a lot of people recommended avoiding Atkins solid corner seals because all else being equal, you’ll see lower compression compared to an OEM corner seal. In this case is the added strength a worthy tradeoff for the compression because you can add a bit more boost to make up for it or are you just not seeing a compression loss on the RX-7 version of the seal?

Dylan,

I have had experience with both. You only crack corner seals if you have an incorrect tuneup. Oem for everything and stay away from Atkins. Their coolant jackets and apex seal springs are not oem and will cause problems in your build. See my thread on rx7 club titled Warped Apex Seal Teardown.

I think Able is one of the best engine builders and I would stick to his advice.

Hi Mike,

Why does Atkins recommend not using their solid corner seals with lapped side housings?

Thanks

Atkins does not recommend lapped side housings in general. From their website:

Side housings have a nitrided surface, which is a heat treating process that diffuses nitrogen into the surface of a metal to create a case hardened surface.

When you lap a side housing you remove this nitrided surface.

We do not offer this service nor do we condone it.

When this nitrided surface is removed excessive wear can occur when using any seal that comes into contact with the side housing, including Mazda corner seals and Atkins Solid Corner Seals.

It can also cause excessive wear to the side seals and oil rings when they come into contact with raw side housings with no nitrided surface.

According to Abel, the Atkins solid corner seals will improve compression over stock, and stock corner seals start to see limitations at certain power levels where solid corner seals become far more necessary and beneficial.