The 700hp-rated CSF core (PN: 8067) measures out at 20” x 12” x 3” (right), while the 600hp-rated Garrett core (PN: 487085-6002) measures out at an almost identical 20.1” x 11.2” x 3” (left). The CSF core uses 16 narrower pressure lines to increase surface area and heat transfer compared to the 13 pressure lines in the Garrett core. The end plates on the CSF core are nearly 4-times thicker than Garrett, which makes welding end tanks easier and ensures a stronger connection.

The 700hp-rated CSF core (PN: 8067) measures out at 20” x 12” x 3” (right), while the 600hp-rated Garrett core (PN: 487085-6002) measures out at an almost identical 20.1” x 11.2” x 3” (left). The CSF core uses 16 narrower pressure lines to increase surface area and heat transfer compared to the 13 pressure lines in the Garrett core. The end plates on the CSF core are nearly 4-times thicker than Garrett, which makes welding end tanks easier and ensures a stronger connection.

The CSF core also configures their core to have ambient cooling fins on both sides of the outer pressure lines, while the Garrett core has pressure lines at the end of the core, which means they are only cooled by one side. This is a pretty clear design win for CSF in my opinion. CSF uses a different fin pitch design for their narrower pressure lines while Garrett appears to use a similar fin design for both the pressure and ambient lines. Please ignore the welding and fin condition of this Garrett core, it has been laying around the shop for years and does not reflect the quality of Garrett products.

The CSF core also configures their core to have ambient cooling fins on both sides of the outer pressure lines, while the Garrett core has pressure lines at the end of the core, which means they are only cooled by one side. This is a pretty clear design win for CSF in my opinion. CSF uses a different fin pitch design for their narrower pressure lines while Garrett appears to use a similar fin design for both the pressure and ambient lines. Please ignore the welding and fin condition of this Garrett core, it has been laying around the shop for years and does not reflect the quality of Garrett products.

We went to work fabricating our end tanks out of 1/8” thick 5052 aluminum sheet.

We went to work fabricating our end tanks out of 1/8” thick 5052 aluminum sheet.

After a few bends and finish-welding by Mario of TSR Fabrication, our end tanks were ready to be welded to the core.

After a few bends and finish-welding by Mario of TSR Fabrication, our end tanks were ready to be welded to the core.

Mario’s welds are just art.

Mario’s welds are just art.

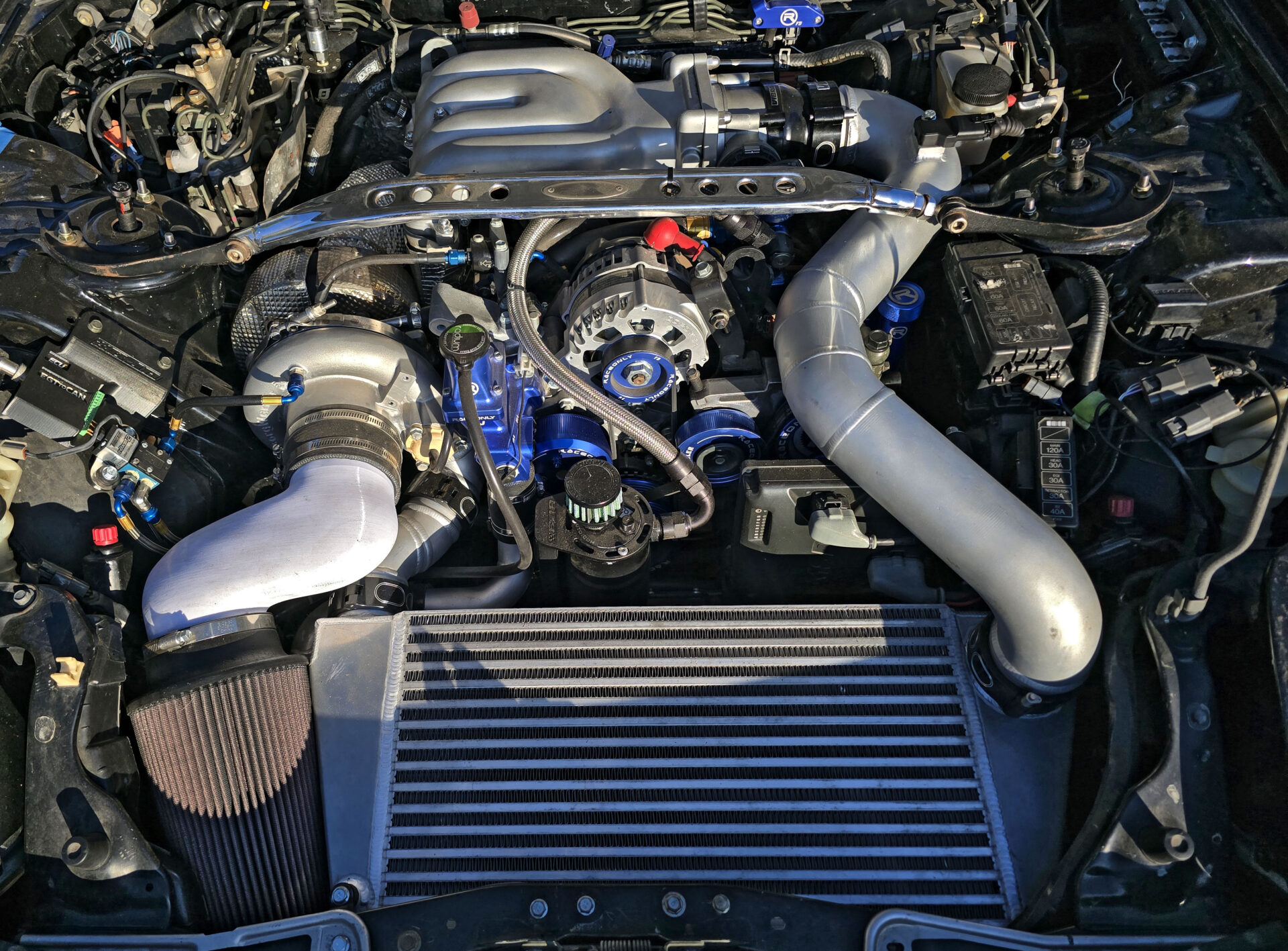

We mocked up the end tanks prior to welding. Air will enter the side of the intercooler with a 2.5” pipe in the short span from the turbo to the intercooler, and then will exit the intercooler with a 3” pipe out of the top of the end tank.

We mocked up the end tanks prior to welding. Air will enter the side of the intercooler with a 2.5” pipe in the short span from the turbo to the intercooler, and then will exit the intercooler with a 3” pipe out of the top of the end tank.

1 comment

That V-mount design and the way the air intake tucks in perfectly to the side is so cool. I still can’t wait to see the end product! Hopefully Mike can get some vids of it out of you for the YT channel.