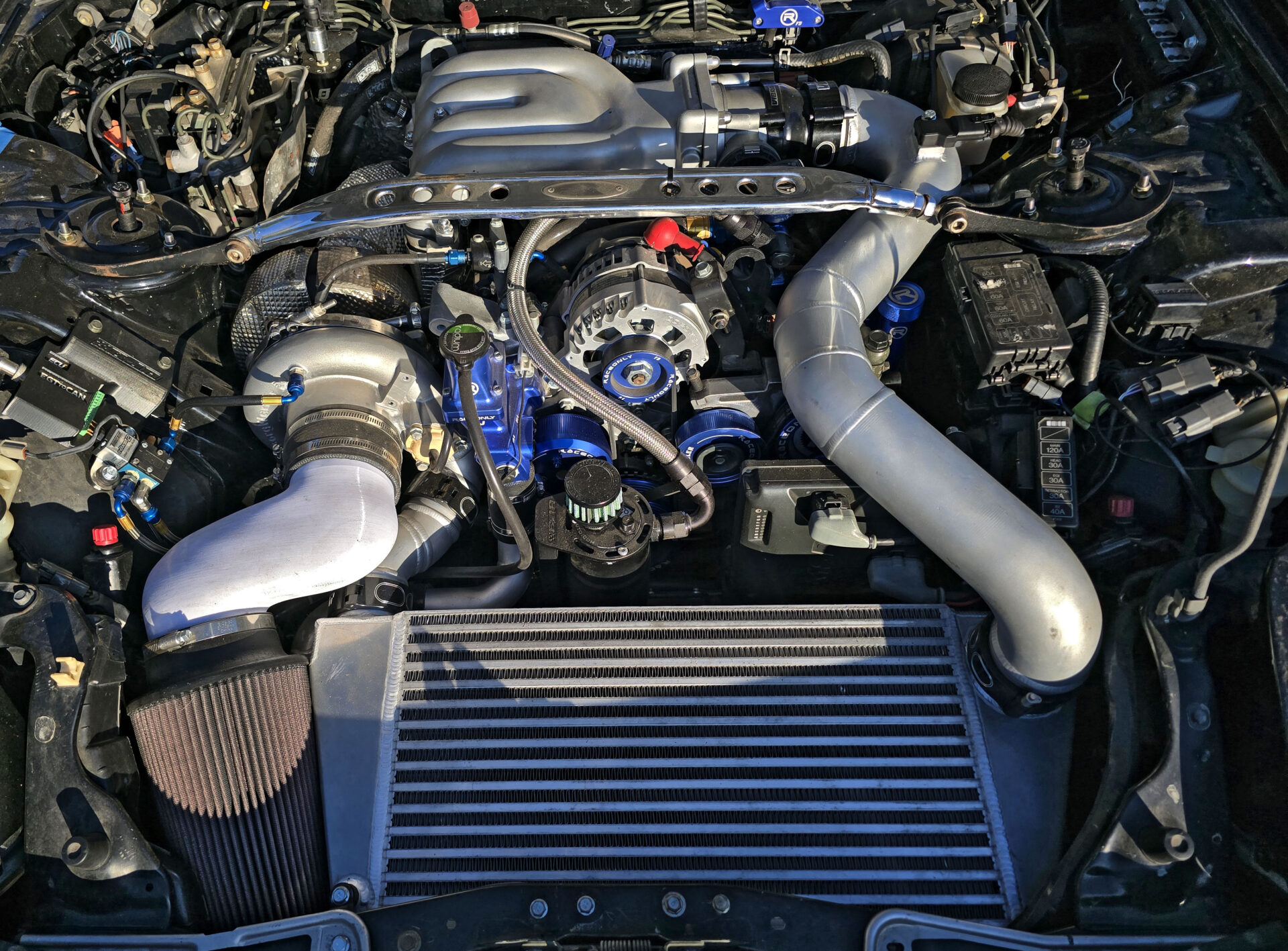

After vapor blasting the charge pipe, we had a completed intercooler and V-mount setup.

After vapor blasting the charge pipe, we had a completed intercooler and V-mount setup.

Looking back and reflecting to where our car started prior to the fire and this entire build, it is pretty cool to see where the car is at now.

Looking back and reflecting to where our car started prior to the fire and this entire build, it is pretty cool to see where the car is at now.

We test fit and tweaked the design a few times of the 3D printed air inlet tube. This positioned the 9” long K&N air filter (PN: RE-0870) right at the opening in the V-mount to ensure the turbo gets fresh, cool, ambient air. We have used K&N air filters on so many projects and continue to be a huge fan of the performance, quality, and reliability of their air filters.

We test fit and tweaked the design a few times of the 3D printed air inlet tube. This positioned the 9” long K&N air filter (PN: RE-0870) right at the opening in the V-mount to ensure the turbo gets fresh, cool, ambient air. We have used K&N air filters on so many projects and continue to be a huge fan of the performance, quality, and reliability of their air filters.

This 9” long K&N filter has a 4” ID flange, a 6” wide base that tapers gradually to a 4.625” OD top. This was the perfect size to maximize the space available in our V-mount layout.

We completed the design of our 3D printed air inlet and printed it out of Nylon for initial testing. Once we are happy with the design, we will print the duct out of PAHT CF.

We completed the design of our 3D printed air inlet and printed it out of Nylon for initial testing. Once we are happy with the design, we will print the duct out of PAHT CF.

Overall, we were very happy with the layout and efficiency of our V-mount intercooler and radiator package. The turbo receives cool, ambient air from the front bumper, and the rest of the air will pack up and create a high pressure area in front of the intercooler and radiator, which will force air through the coolers due to creating a big pressure differential across the heat exchangers. This is one of the most efficient and cohesive V-mount setups that have been made for an RX-7 and we are looking forward to testing it soon.

1 comment

That V-mount design and the way the air intake tucks in perfectly to the side is so cool. I still can’t wait to see the end product! Hopefully Mike can get some vids of it out of you for the YT channel.