,

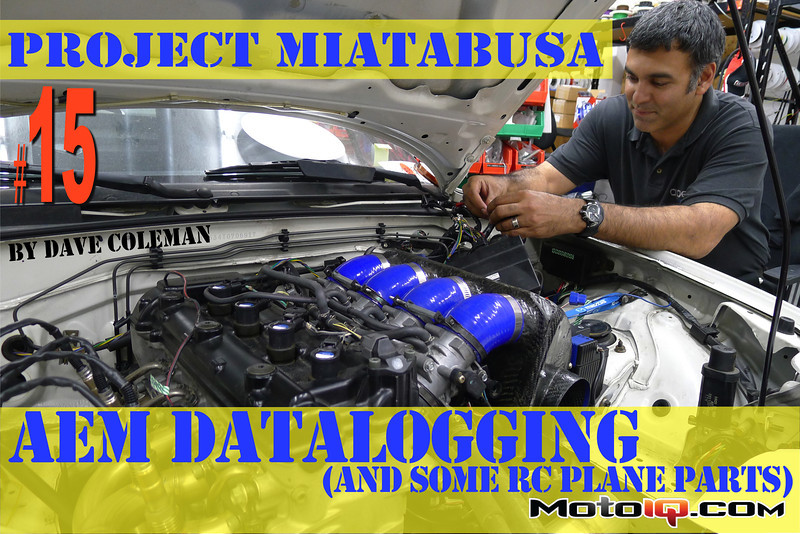

Turns out there are a few other things that need to be connected to the plenum too, including the crankcase breather hose. We made a quick breather hose fitting by sacrificing a Sharpee. First, coat with mold release wax,

then wrap with resin-soaked carbon fiber,

and apply compressive force with some stretchy plastic wrap.

After a few hours of cure time, the bung can be finish shaped with this handy portable carbon fiber lathe.

Gluing the bung directly above the crankcase vent let us use the breather hose as a support bracket for the featherweight plenum.

The intake air temperature sensor originally threaded into a brass fitting that was moulded into the plasic Hayabusa air box. We fretted over how to mould in some kind of threaded boss before we finally woke up and realized all we needed was a nyloc nut to hold the sensor in place. This is another advantage of giant air filter hatch on the front of the plenum. You can easily reach your whole hand into the plenum to install things like this.

Finally, we needed a small bung to connect a vacuum hose from the plenum to the barometric pressure sensor. Where do you find a small carbon fiber tube for something like that?

The Harbor Freight Yellow Bee is an amazing example of Chinese currency manipulation. For $30, they sell a complete, ready-to-fly RC plane complete with radio, battery and charger. Built on the other side of the planet, sent here on a boat, customs duties paid, marked up by retailers, and still only $30? Something is so wrong.

And yet so right…

Yellow Bees are quite tricky to fly. They have no control surfaces, just two motors with differential throttle control. Want to climb? Go faster. Want to come down? Wait. Turn right? Use the left motor. There's a hell of a learning curve on the Yellow Bee, and as a result, I have quite a collection of carbon tail booms in the garage.

Here's how this piece of carbon ended up in my plenum…

And here's that tail boom now…

Dyno footage really soon, I swear!

Sources: