,

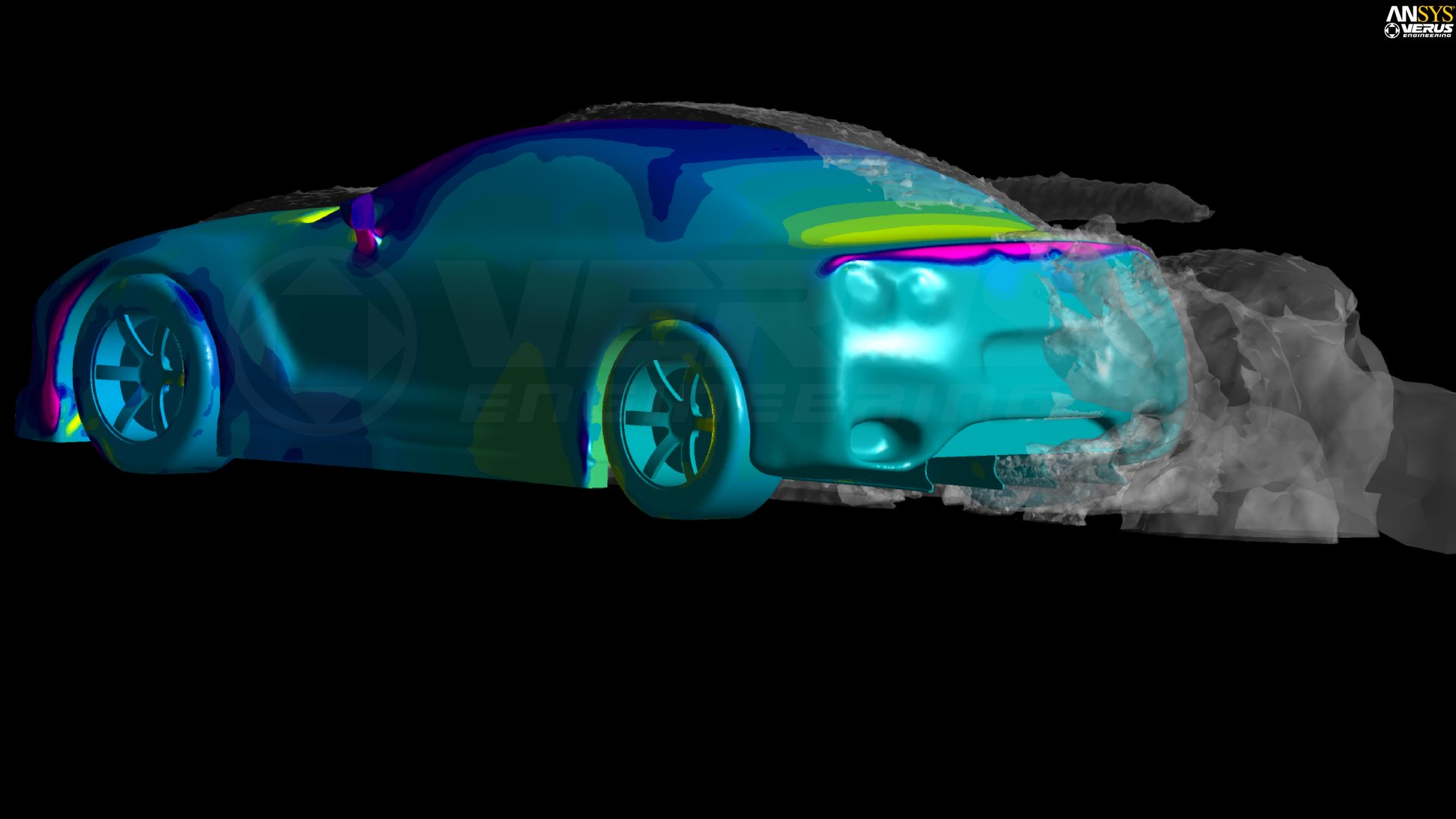

Here is a view of the Verus Engineering strakes looking upward. The shape, mounting angles, and geometry of the strakes have all been determined with CFD analysis.

You can see how the bottom of the GT-R is just about a flat bottom from the factory with lots of drag reducing plastic panels with venting to keep heat-sensitive under car parts cool.

Here is a view of our modified diffuser looking forward from the throat of the diffuser outward. The placement of the strakes increases the diffusion and generates vorticities that attach the air flow to the diffuser roof better and improve the flow in the car’s wake.

The Verus carbon panel covers the one part of the GT-R’s undercarriage that is not a flat bottom. This is where the exhaust system and driveshaft can create turbulence in the critical area at the entrance to the diffuser.

Considering the great amount of time Nissan devoted to reducing drag on the GT-R, including a lot of small aero details that are not exactly cheap to implement, we find it odd that they didn’t do anything to clean up this area of obvious improvement.

The entire Verus Engineering aero system gives the GT-R a near race car like flat bottom and effective rear diffuser.

The good thing is that the stock accessibility of under car components for service, adjustment, and repair remains the same. If you have ever had to work on a flat-bottomed race car, you will know what we mean in that it can be a bitch to work on these cars, especially when doing chassis setup or major repairs at the track.

Related