,

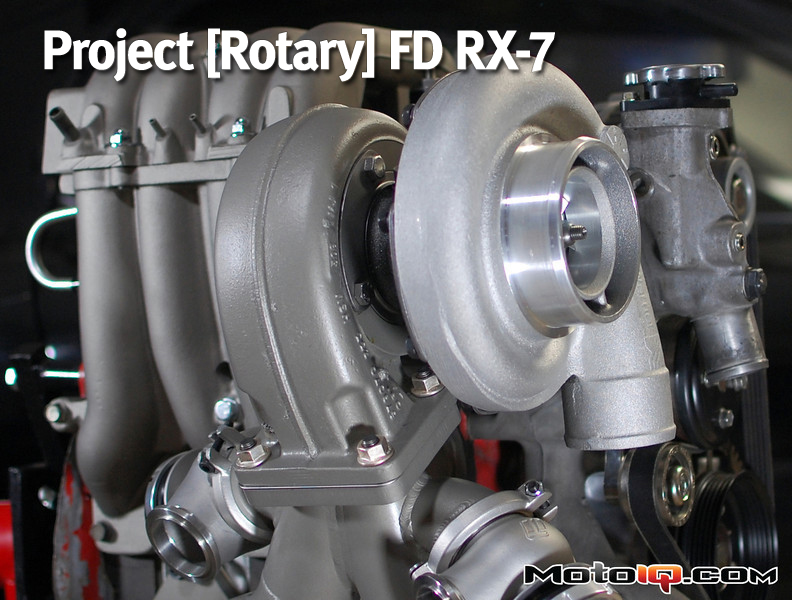

With all the exhaust and wastegate tubing complete we can start routing the oil feed, oil drain, and wastegate vacuum hoses. One benefit of using a Borg Warner AirWerks turbo is that the center section is not watercooled, so there is no need to plumb coolant hoses as well. This is nice because plumbing hoses around the turbo and manifold can be frustrating due to the fact that they are routed near the hottest components in the engine bay. To make sure the hoses don't fail during operation, special parts and/or precautions need to be used.

Earl's Speed-Flex PTFE lined stainless braided hose and Earl's Speed-Seal steel hose ends are used to get turbo feed oil from the engine to the turbo. PTFE lined hose has a higher working temperature (~450F) than rubber lined hose (~300F), so it is perfect to use near turbo components. Various other Earl's adapter fittings mate to each end of the -3AN hose assembly to connect it to the engine and turbo.

Earl's Speed-Flex PTFE lined stainless braided hose and Earl's Speed-Seal steel hose ends are used to get turbo feed oil from the engine to the turbo. PTFE lined hose has a higher working temperature (~450F) than rubber lined hose (~300F), so it is perfect to use near turbo components. Various other Earl's adapter fittings mate to each end of the -3AN hose assembly to connect it to the engine and turbo. Pictured here are the components that make up the turbo oil drain. The Vibrant Performance -10AN oil drain flange mates to the turbo and the Earl's weld-on -10AN fitting mates to a modified oil drain tube from the factory twin turbo system. Between the two is a hose assembly made from -10AN Aeroquip Socketless hose and fittings. This assembly is covered in a DEI silicone/fiberglass thermal sleeve to keep heat away from the hose.

Pictured here are the components that make up the turbo oil drain. The Vibrant Performance -10AN oil drain flange mates to the turbo and the Earl's weld-on -10AN fitting mates to a modified oil drain tube from the factory twin turbo system. Between the two is a hose assembly made from -10AN Aeroquip Socketless hose and fittings. This assembly is covered in a DEI silicone/fiberglass thermal sleeve to keep heat away from the hose. The turbo oil feed hose is simple to route on the 13B-REW. All it takes is a M14x1.5 adapter fitting threaded into the engine and a hose assembly routed across the top of the engine to the turbo. The turbo on the Full-Race manifold sits high enough in the engine bay that a 90-degree fitting on the turbo is mandatory.

The turbo oil feed hose is simple to route on the 13B-REW. All it takes is a M14x1.5 adapter fitting threaded into the engine and a hose assembly routed across the top of the engine to the turbo. The turbo on the Full-Race manifold sits high enough in the engine bay that a 90-degree fitting on the turbo is mandatory. The turbo oil drain hose, unlike the feed hose, can be more troublesome. It is a harder hose to route because it is much larger and has to pass by the turbine housing and manifold on its way to the engine. It is also important (though it can't be seen well in this picture) that the turbo center section is oriented in a way that the drain is as close to vertical as possible. Generally 10-15 degrees off vertical is considered the limit.

The turbo oil drain hose, unlike the feed hose, can be more troublesome. It is a harder hose to route because it is much larger and has to pass by the turbine housing and manifold on its way to the engine. It is also important (though it can't be seen well in this picture) that the turbo center section is oriented in a way that the drain is as close to vertical as possible. Generally 10-15 degrees off vertical is considered the limit. Silicone vacuum hose is used to plumb the wastegates and boost control solenoid. All this hose is 6mm inside diameter with 3mm wall thickness. 1/4″ brass tees and 1/8″ NPT elbows are used so that they won't melt like many cheap plastic ones do. A standard 3-port MAC solenoid for boost control is also shown with a mounting bracket and rubber isolator to keep vibration from damaging the solenoid.

Silicone vacuum hose is used to plumb the wastegates and boost control solenoid. All this hose is 6mm inside diameter with 3mm wall thickness. 1/4″ brass tees and 1/8″ NPT elbows are used so that they won't melt like many cheap plastic ones do. A standard 3-port MAC solenoid for boost control is also shown with a mounting bracket and rubber isolator to keep vibration from damaging the solenoid. The boost control solenoid is mounted to the right fender wall behind the ABS unit. This location should keep the solenoid away from heat, keep vacuum hose lengths short, and make wiring easy.

The boost control solenoid is mounted to the right fender wall behind the ABS unit. This location should keep the solenoid away from heat, keep vacuum hose lengths short, and make wiring easy. Plumbing the vacuum hoses for the wastegates on a twin scroll turbo system can look complicated, but realistically it is the same as with a single wastegate except more tees. Note the two amber colored zipties on the hoses. These are made of a plastic material called PEEK and can withstand temperatures in the 450-500F range (unlike typical nylon zipties which can only handle about 210F). When the engine is installed in the car for the final time these zipties will be on each hose connection.

Plumbing the vacuum hoses for the wastegates on a twin scroll turbo system can look complicated, but realistically it is the same as with a single wastegate except more tees. Note the two amber colored zipties on the hoses. These are made of a plastic material called PEEK and can withstand temperatures in the 450-500F range (unlike typical nylon zipties which can only handle about 210F). When the engine is installed in the car for the final time these zipties will be on each hose connection.