,

|

| The thin foam strip was the perfect thickness to seal off the top of the radiator. The stock radiator uses a similar foam strip to seal off the top. |

So we went through a fair amount of work to see results, and results we got. I drove the car hard, taking it to redline instead of short shifting as I had the session before to push the coolant system as hard as possible. With an ambient air temp of 97F, the highest we could get the coolant to hit was 97C! Compared to the stock radiator, the coolant was 6C cooler even though the air temp was 12F hotter!

|

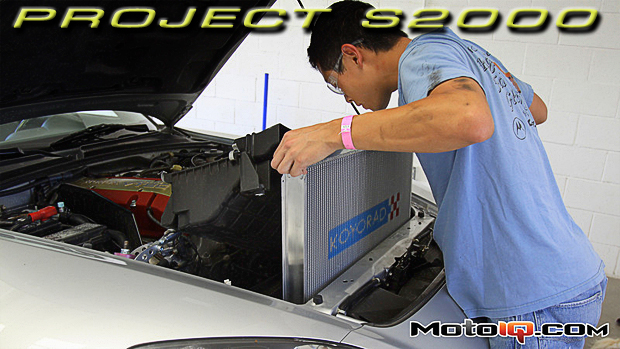

| Because of the extra thickness of the Koyo, it places the fans and coolant temp sensor farther back into the engine bay. The wires are really stretched to make the reach, so we cut the plastic mounting tabs of the wiring to provide enough slack. |

The Koyo performed great at the track, but there was still room for improvement. As was demonstrated on Wes’s Project 200SX, proper sealing of the radiator can vastly improve cooling efficiency by forcing more air through the radiator. A quick look down the weather stripping isle of Ace Hardware resulted in buying ~$10 worth of foam used for the sealing of window/wall mounted A/C units. One strip of foam across the top of the radiator and one down each side seals off the escape routes for air around the radiator.

|

|

| To seal off the sides of the radiator, two 15” strips were cut. I found the best method to install them was to go through the front bumper opening. |

For a track-worthy car, we’ve gotten the wheels, tires, brakes, and coolant cooling sorted. The most obvious need now is an upgraded oil cooling system. There are some other improvements in the works too. The best aspect of all of these upgrades has been that the car has improved in every way with absolutely no negatives. No harsh ride, no squeaky suspension parts, no loud noises, no compromises whatsoever! There’s more to come.

Sources