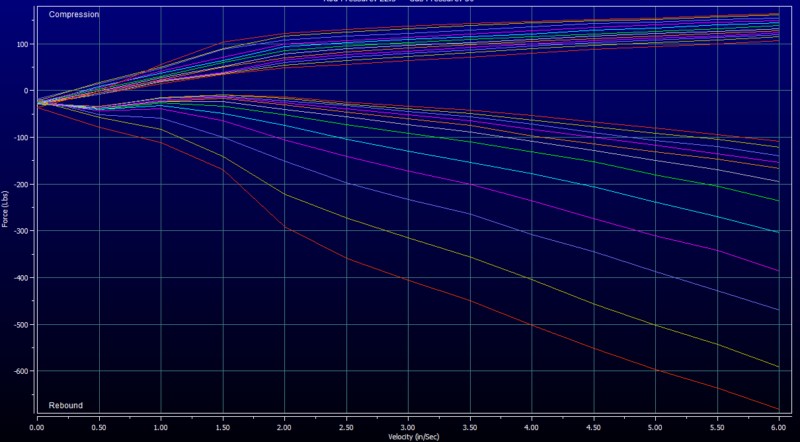

The revalving process was quite tedious. S3 reconfigured, reassembled, and redynoed both front and rear shocks about 10 times each to fine-tune each adjustment and configure the target forces of where we wanted them to be. Then we mirrored the setup to the other shocks, and dynoed again, only to find some inconsistencies where we discovered damaged tubes that had to be honed and cleaned to ensure we got accurate readings and deliver final before and after shock dyno results that we were happy with. As you can see in the before dyno charts, the rebound was nonlinear due to wear and tear of the O-rings, seals, and damaged components, which resulted in gas and oil blowing by the pistons.

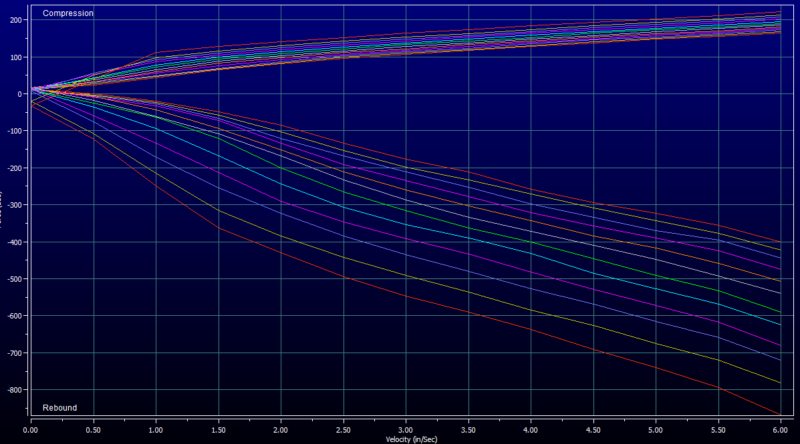

After the rebuild and revalve not only are the charts more linear, but compression, which controls unsprung weight, is much tighter, and rebound, which controls the sprung weight, which is what controls your car is more consistent across the board.

After the rebuild and revalve not only are the charts more linear, but compression, which controls unsprung weight, is much tighter, and rebound, which controls the sprung weight, which is what controls your car is more consistent across the board.

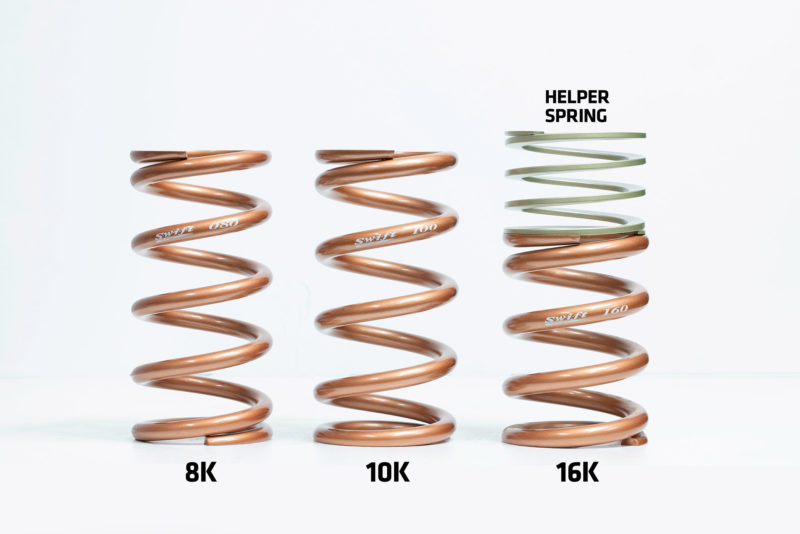

We decided to update the springs with some new Swift Springs metric coilover spring replacements. Swift Springs runs their own metal foundry, which allows them to design and produce purpose-built metal material called HS5.TW. This combined with their proprietary winding method allows Swift to provide a lightweight spring with a very consistent spring rate and with exceptional durability against loss of spring height, also known as spring sag. Their own durability testing has also shown these characteristics to carry over throughout the entire stroke and lifecycle of their springs. We were able to reach out to Swift for spring rate/configuration advice, and they were extremely helpful in providing insight to choosing the right spring setup for our set-up If you’re a serious enthusiast we highly recommend reaching out to them for your custom setup.

The original BuddyClub spring rates were 10K in the front and 8K in the rear. You could swap them out for the same spring rates and height if you’d like. You can see here the original BuddyClub springs have an extra coil wind when compared next to the Swift spring.

The original BuddyClub spring rates were 10K in the front and 8K in the rear. You could swap them out for the same spring rates and height if you’d like. You can see here the original BuddyClub springs have an extra coil wind when compared next to the Swift spring.

However, we decided to go with different spring rates, lengths, and helper springs. The reason why we are running a shorter length spring than what came with the BuddyClubs is that we are increasing the spring rate to the point where an 8″ length spring’s worth of stroke is not needed since we are running a much higher spring rate that will not need as much compression travel. The reason why we are running shorter rear springs than the front is that the rear shock stroke is shorter, and the bump stop will protect the spring from going beyond its useable stroke. Keep in mind that dynamic compression from static ride height will exponentially decrease because of the higher spring rate. Ideally, you want to run the shortest useable spring for your setup, however, if you go too short, you will run into coil bind. If we were to run an 8″ 16kg spring on your car when you only need a 6″ spring’s worth of stroke, then all you will be doing is packing on weight onto your suspension assembly, nullifying the advantage of our springs being lighter.

A quick theoretical calculation to help make sense of it all:

- With a stock rate of 10kg (559lbs per inch), with 1000 lbs of load on the spring, at static ride height, your spring will compress 1.8″

- With a new rate of 16kg (894lbs per inch), with 1000 lbs of load on the spring, at static ride height, your spring will compress 1.1″

For the front, we upgraded the springs with ID 65MM (2.56″) – 6″ Length (PN: Z65-152-160) at a 16KG (896LBs) spring rate with a usable stroke of 2.7 inches and max stroke of 3.5 inches.

For the front, we upgraded the springs with ID 65MM (2.56″) – 6″ Length (PN: Z65-152-160) at a 16KG (896LBs) spring rate with a usable stroke of 2.7 inches and max stroke of 3.5 inches.

For the rear, we upgraded the springs with ID 65MM (2.56″) – 5″ Length (PN: Z65-127-160) at a 16KG (896LBs) spring rate with a usable stroke of 2.5 inches and a max stroke of 2.9 inches.

In addition, we added Swift helper springs (PN: H65-060-015) 1.5KG (84LB) spring rates to have the ability to set droop travel since we are going to be losing some due to the higher spring rates. This will help allow the spring to stay mounted on the coilover perch when the shock is under negative or zero load. It is ideal to run helper springs on setups where you cannot preload the main spring due to height issues or when experiencing springs coming loose from the coilover perch.

In addition, we added Swift helper springs (PN: H65-060-015) 1.5KG (84LB) spring rates to have the ability to set droop travel since we are going to be losing some due to the higher spring rates. This will help allow the spring to stay mounted on the coilover perch when the shock is under negative or zero load. It is ideal to run helper springs on setups where you cannot preload the main spring due to height issues or when experiencing springs coming loose from the coilover perch.

While the exterior housing is manufactured by BuddyClub, the combination of custom Swift spring rates, revalving, and new fluids, this is now an entirely different coilover altogether.

While the exterior housing is manufactured by BuddyClub, the combination of custom Swift spring rates, revalving, and new fluids, this is now an entirely different coilover altogether.

6 comments

On second page bottom – where nut tightening is happening. Isn’t the tech supposed to be holding shocks piston rod ehile doing so? Not to damage valving.

That would be more of a question for them, not us.

If you brace the shaft, you have a chance of scratching the shaft resulting in the shocks as good as blown because they will slash right through the seal

Do you do other shocks?

You would need to reach out to your local suspension or shock specialist to see if they offer rebuild and revalve services. You can reach out to S3 Suspension and see if your shocks are rebuildable and if they can be shipped in for service.

https://s3suspension.com/

Any idea about how many liters of shock oil per coilover? Trying to see how many bottles I would need. Also that link shows its motorbike race shock oil, is that correct?