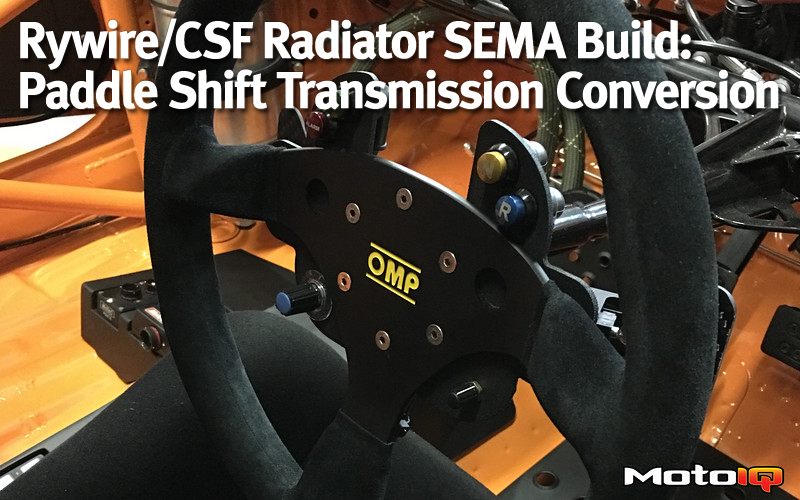

Rywire/CSF Radiator SEMA Build: Taking An Integra From A Row Boat To Paddle Shifters

Paddle shift conversions can be done a million different ways using various components, theories, hidden secrets and technology that is well above my pay grade. What you’ll see here is not by any means the only way to do it, nor is it even the “correct” way to do it. I thought long and hard, weighing the costs vs. benefits, the pros and cons, and this is what I came up with. I am a sick-in-the-head individual who gets off by learning crazy ways to make normal cars do abnormal things, and in the process blow the minds of the inside-the-box thinkers. If you are asking yourself “Why?” then maybe this build isn't for you. But, if you are interested in learning what goes on in my head and how I came up with my paddle shifted commuter car, here is how I did it.

Let’s start by listing out the components of our system.

Here we have the power behind our system, the sequential transmission. This is the vital piece, if you don't have this piece then good luck with the rest. A sequential gear box is more than a gear set, or even a shifter. The sequential trans uses a drum inside the box that spins in given directions to select the gears in order (1-5 and reverse in this case). Each push of the lever, or click of the paddle requests the next gear in a forward direction. There is also a rotary potentiometer “keyed” into the end of the drum, which will give the ECU information as to what gear the transmission is currently in based on the voltage the “POT” sees.

Here we have the power behind our system, the sequential transmission. This is the vital piece, if you don't have this piece then good luck with the rest. A sequential gear box is more than a gear set, or even a shifter. The sequential trans uses a drum inside the box that spins in given directions to select the gears in order (1-5 and reverse in this case). Each push of the lever, or click of the paddle requests the next gear in a forward direction. There is also a rotary potentiometer “keyed” into the end of the drum, which will give the ECU information as to what gear the transmission is currently in based on the voltage the “POT” sees. The next key component in this build is the brain of the system, the ECU or GCU (Gear Change Unit). Since the ECU I have chosen has all the necessary onboard capability to handle the gear shifts there is no third party unit needed. The MoTeC M1 with its new GPR-P package has the ability to do it all. MoTeC is no stranger to complex systems, and when I heard about the new GPR package with the additional paddle capability (GPR-P) I had to have it.

The next key component in this build is the brain of the system, the ECU or GCU (Gear Change Unit). Since the ECU I have chosen has all the necessary onboard capability to handle the gear shifts there is no third party unit needed. The MoTeC M1 with its new GPR-P package has the ability to do it all. MoTeC is no stranger to complex systems, and when I heard about the new GPR package with the additional paddle capability (GPR-P) I had to have it. Next up is the air source for shifting. We went with a mini compressor from Thomas. This unit will turn on when the air tank is running low on air. It can be programmed to come on (or not come on) whenever it needs to. It is a slightly more compact version of the traditional air ride compressor but the theory behind it is basically the same. This particular compressor draws about 15amps when running. That is equivalent to 1 of my 3 fuel pumps, and uses about the same as my water pump.

Next up is the air source for shifting. We went with a mini compressor from Thomas. This unit will turn on when the air tank is running low on air. It can be programmed to come on (or not come on) whenever it needs to. It is a slightly more compact version of the traditional air ride compressor but the theory behind it is basically the same. This particular compressor draws about 15amps when running. That is equivalent to 1 of my 3 fuel pumps, and uses about the same as my water pump.