,

This is the first fiberglass part pulled off the plug made from based chopped mat glass and clear resin. The translucence allowed the fabricators to check clearances visually. If there were any clearance issues, the fiberglass parts can be cut up and modified at much less of a cost than cutting up a finished carbon part. The final part is made from carbon of course. It turns out there was a clearance issue with the Full Race header, but the vent/louver was going to be used anyway. Notice a bump was added to the top of the original box flare for tire clearance.

Here is the front end laid up in the mold and all bagged up. Vacuum bagging prevents excessive resin in the final part, increases strength of the part and reduces the final weight of the part due to less resin being left in the part. Vacuum bagging is the best compromise between a “wet” and “dry” carbon part with wet parts typically being resin rich (and therefore heavier) and dry parts requiring pre-pregged (pre-impregnated resin) carbon cloth, expensive high strength molds, and an expensive autoclave to produce parts.

Here are the vents and louvers mocked up on the gel coated front end. The vents and louvers were made from carbon for the final pieces.

And here are the final pieces before bonding to the carbon one piece front end.

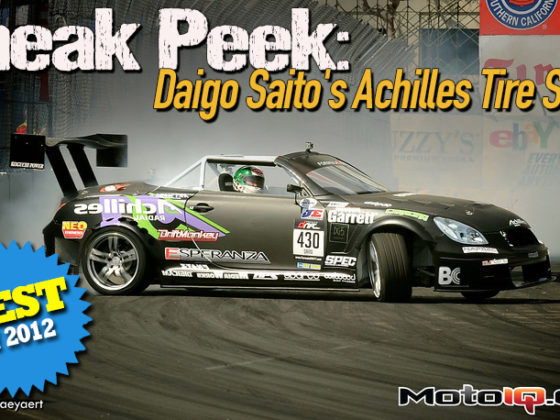

Here's the final front end with everything in place including the splitter. I'm not sure if you would call the upper pieces canards or if they would constitute what makes up a wing, but whatever they are, they work damn good. Andrew mentioned that the current aero package, while very effective, can be refined by making it more efficient. Through more CFD analysis and testing, the drag can be reduced while producing the same amount of downforce.

Here the skeleton of the outer fender flare is being built in space. I had to look at this picture a couple times to figure out what exactly was being fabricated.