Subaru Clutch Forks Cracking Under Pressure? Say It Isn’t So!

by Eric Hazen

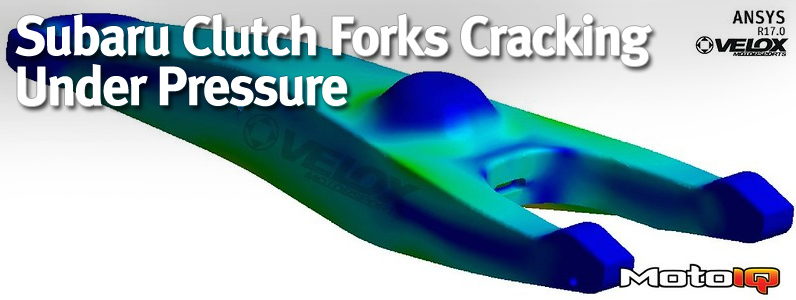

Subarus have roamed the streets, tracks, and dirt for decades, with hundreds of thousands of upgrades available for nearly every aspect of these beloved cars. Yet, one crucial part seemed to be passed over- the clutch fork! The clutch fork is Subaru’s Achilles heel. The clutch fork’s job is simple – disengage the clutch when you want to change gears. However, the stock part is prone to breakage and premature wearing of the pivot, especially when a performance clutch with higher clamping forces is used.

Even if the fork doesn’t break, the area around the fulcrum wears thinner and starts to flex which makes for a stiff and inconsistent pedal as the wear and flex is enough to change the motion ratio of the fork. It is common knowledge among Subaru owners to change the fork when servicing the clutch, even with fairly low mileage cars and stock clutches.

So how did Velox get “forked” into developing a new part?

Sometime in May of 2016, a customer contacted Velox regarding the failure issue with his FRS/BRZ clutch fork. In the BRZ/FR-S tuning community, various other owners were complaining about the issue and a few had even broken their forks. At first, the engineers at Velox did not believe it; it is a simple part, 3mm wall steel should handle the loads, and it is not exactly rocket science. The further Velox dug into the issue and the more people they spoke to, the more they realized that they needed to come up with a solution for the now growing problem.

What is occurring and why?

Like most components that are original equipment manufacturers’ design, they are designed for certain loads and service life. When enthusiasts install a stronger clutch and heavier sprung pressure plate to deal with more horsepower and torque, that clutch fork is being worked extremely hard. As engineers, would say, the fork is being worked near or even past the materials’ yield strength and is being plastically deformed. Continued operation creates micro stress fractures that will continue to propagate until ultimate failure and fracture occurs.

Material properties, yield strength, and deformation:

In the section below is an interesting small crash course into material properties, yield strength, deformation and stress. The content is a bit dry but is important to fully understand what is occurring to the clutch fork. The focus will be on metal material properties as that is what is used in the clutch fork.

As a force is applied to a material, a stress is produced. The applied force causes the material to change shape as well, which in engineering jargon is called deformation. There are two forms of deformation a material exhibits when a force is subjected on it: elastic deformation and plastic deformation. Elastic deformation is perfectly normal; as the force is taken off the material, the material goes back to its original shape and form. Perfect! Plastic deformation is not so much in this case. Plastic deformation is a permanent change to the material’s shape. At an atomic layer, atom bonds are breaking. The material’s strength is degrading and repetitive loading will cause a failure.

Yield strength is an indication of the maximum stress that a material can see without causing plastic deformation. Yield strength is typically given in PSI or kPa/mPa, which is Kilopascals or Newtons of force over a square meter (for you metrically impaired, a Newton is the force required to accelerate one kilogram at one meter per second per second. One kilopascal is 0.145 PSI.). Yield Strength is the numerical cross-over point from elastic (good) to plastic (bad) deformation.

The Stress Strain Curve