,

Production ready, clutch out, and back on the gas:

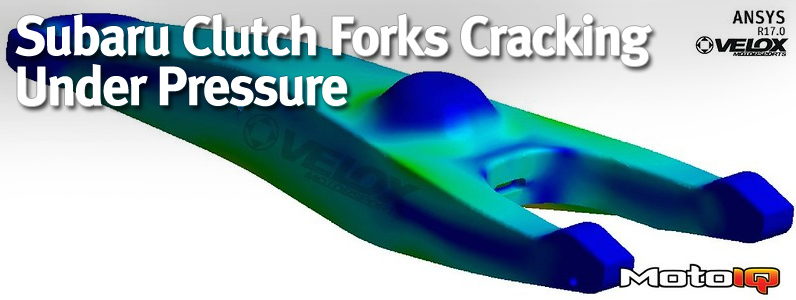

After the design of the parts were verified through fit verification of the rapid prototype model, it was time to go into production. The production forks were CNC machined out of 4130 annealed stock. In the areas of contact with the fork pivot, throwout bearing, and slave cylinder, the cutting path was made at a fine pitch to give a smooth finish to these areas that rub against other area. The rest of the part had a coarser tool path to speed machining time.

After machining, the forks are given a black oxide finish. Black oxide is a surface conversion finish for ferrous metals where the part is dipped in a hot bath consisting of zinc hydroxide to convert the surface of the steel to black magnetite. This matt black coating is then treated with wax to produce a rust resistant surface finish.

While a new clutch fork was being designed, the clutch fork pivot was redesigned as well. The stock mild steel pivot galls, wears and corrodes. These factors help contribute to a stiff and inconsistent clutch feel. The new Velox part is made of hard, strong and wear resistant 17/4 precipitation hardening stainless steel.

This is the ideal material for the pivot and it is CNC-machined with an ultra-smooth finish for less friction. The new pivot and clutch fork assures that you will always have a smooth and consistent clutch action for the life of your car!

So far, Velox Motorsports has heard nothing but glowing reviews from this modification and the clutch pivot; from clutches that operate again to a much more consistent clutch feel. If you own a Subaru and are upgrading your clutch, we highly recommend looking into our clutch fork as well. The FRS/BRZ/GT86 clutch fork shares the same clutch fork as 278 vehicle variants in the Subaru line up and the 2015+ WRX clutch fork shares its clutch fork with 72 other vehicle variants.

In the world of Subaru, tuning the clutch fork is known to be a problematic item that is a high wear and consumable part. The Velox clutch fork solves the problem once and for all promising a nearly infinite service life and smooth and consistent clutch action for the life of the vehicle. You can’t beat that!

Sources