,

As the initial pulse of high pressure, high energy gas leaves the end of the primary tube and is diffused in the larger diameter header collector; the point where all of the primary tubes merge, a pressurized pulse of sound energy just like a musical note is generated, much like that of an organ. Some of it travels down the exhaust pipe and out into the open air. This is exhaust noise that you hear. The rest of it is reflected back up the primary pipe towards the exhaust valve. This sonic pulse has quite a bit of energy as your ears can attest if you have even been around uncorked race cars.

|

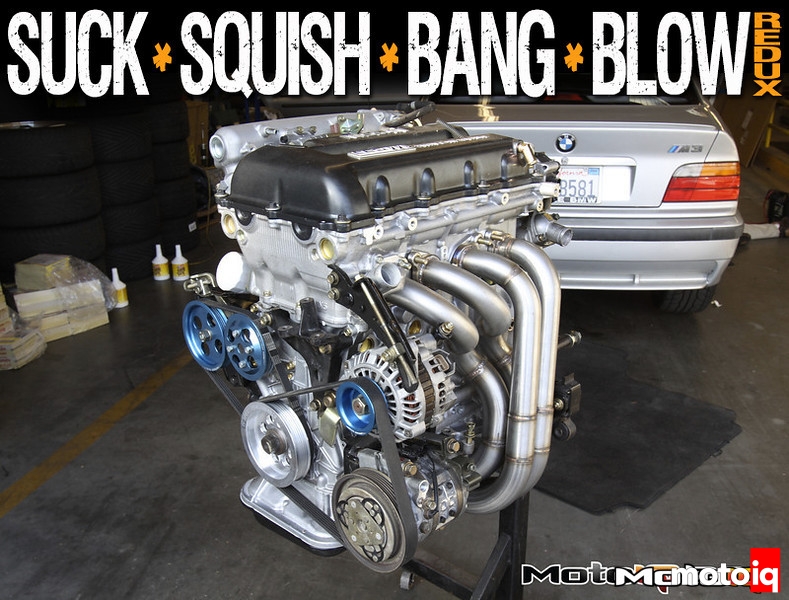

| A picture is worth a thousand words. To make more power the timing of the two low pressure events, the low pressure rarefaction and the reflected sonic wave is critical. Getting the timing to where it helps out on overlap is controlled mostly by pipe length and diameter just like a musical instrument. |

This reflected sonic pulse initially travels up the primary tube at sonic speed which is usually around 1100-1900 feet per second in thin hot exhaust gas, causing a slight rise in pressure at the valve. The pulse travels into the combustion chamber and is then reflected back down towards the open end of the primary pipe trailing a rarefaction behind it. If the pipe is of proper length and diameter, this reflected wave can be exploited to lengthen the amount of time that the condition of low pressure exists around the exhaust valve well into the overlap period causing a further improvement in scavenging.

|

| An all motor 4 cylinder drag car is the sort of application where headers make the biggest difference due to the large cams and high amounts of overlap. Custom or at least purpose built headers are essential for this sort of engine build. Bisimoto Engineering makes semi custom headers for all out drag use as shown on their Insight drag car. |

This explains why some engines are relatively unresponsive to headers while others really respond to a properly designed header. The Ford and Honda Motors we talked about earlier have very little overlap in their stock cam profiles so the headers could not improve scavenging very much. On the other hand, it's possible for a proper header to make over 100 hp on a high strung, big cammed, fully built all motor class 4 cylinder drag car over a poorly designed header or stock exhaust manifold.

The third reason why headers works is pretty obvious, by reducing backpressure with straighter, less kinked tubes with smooth bends, the flow of exhaust is less impeded when exiting the engine. As we discussed in my last column, an engine is a giant air pump, less restriction means more pumping efficiency. In addition, the long individual runners of a header prevent the exhaust blast from one cylinder from blowing into the next cylinder in the firing order that happens to be on overlap. To the surprise of most, the third reason is often the smallest contributor to power gains.

|

| DC Sports makes decent quality off the shelf street headers for a variety of cars. This is a 4-1 Honda B motor application. |

Because a header is tuned like a musical instrument, a header can only be optimized to produce the greatest scavenge improving vacuum in a band of several hundred rpm.

In a nutshell without going into a lot of math some general guidelines for selecting a header are that shorter primary runners and or bigger in diameter primary runners are better for top end power. This has to do with travel time of the main initial exhaust gas pulse and the reflected low pressure acoustic pulse in relationship to the engine's overlap period. In the same way that a piccolo is a higher pitched instrument than a clarinet, a shorter, fatter primary pipe is better for higher rpm as the pulses have a shorter distance to travel. Conversely, a longer and or thinner in diameter primary tube is better for lower rpm for the same reasons as above. The cam's duration and overlap timing also has a lot to do with the optimal dimensions of the header's pipes as well. Generally the later the opening point of the exhaust valve, the shorter the header primary pipes must be.