Since the car is lowered, to help keep the roll center above ground height and minimize bump steer, we installed the Roll Center and Bump Steer Correction Kit from SuperPro. This reduces body roll and fall over on the front tires due to not enough negative camber gain in roll which ends up limiting the tire grip on the track and can cause understeer where it’s not wanted. The kit helps prevent bump steer by correcting improper angles tie rod angles. By eliminating bump steer as much as possible and keeping the proper roll center, seconds in lap times can be gained easily since our goal of tire contact will be at an all-time high. It also helps the life of the Yokohama A052 that we’ll be running all season, saving money in the long run.

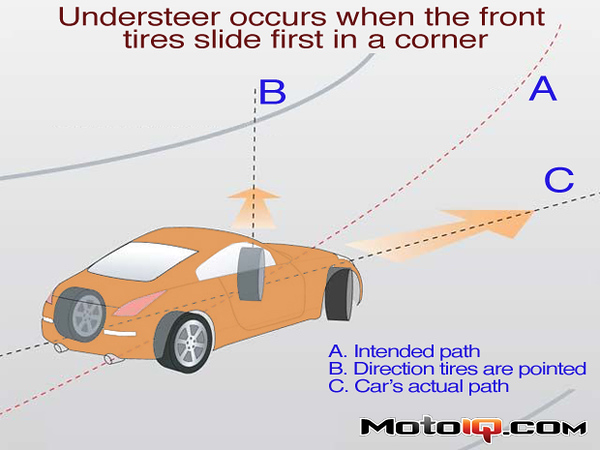

Up next on our overhaul with SuperPro, we chose their 26mm front sway bar 2-position adjustable and the 24mm rear swaybar 2- position adjustable along with the sway bar reinforcement kit. We made sure the higher roll rate was installed in the front to reduce roll and had it stiffer than the rear, which was set as loose as it could go, to get the desired slight understeer. The sway bar acts a torsional spring connecting the right and left sides and helps maximize our lateral grip by one side being pushed upward and the other side is compressing downwards, shifting the weight on the inner tire during a turn. As less weight is transferred to the outer tire and the body stays flatter, meaning more traction and more speed can be gained during turns which equals lower lap times!

SuperPro uses Polyurethane bushings which keep the sway bars from deflecting as it would with rubber OEM bushings. The Sway bar reinforcement kit helps the rear swaybar mounting point’s rigidity, reducing the flex that can affect the function and performance gains. In addition to the sway bars we also selected SuperPro’s Sway Bar Links for the front axle and their HD Endlink Set for the rear axle. Since we dropped the ride height and changed the geometry of the suspension we’ll need the sway bar links and end links to be adjusted to keep the sway bar angle correct. Super Pro’s sway bar links are able to be adjusted from a length of 75mm to 85mm to help maximize adjustability on the sway bars positions. They’re made of 6060-T5 Alloy which allow allows for a small weight reduction opportunity. They also use a ball joint which helps for lower friction and a longer life of use on top of eliminating link flex. The HD Endlink Set are non-adjustable but have a little bit of a longer reach to mounting points without any binding. Just like the front endlinks, these also are built to eliminate flex, deflection and remain more rigid than the OEM endlinks.

4 comments

Any time urethane is mentioned it should automatically include the Teflon tape trick (where you put a layer of Teflon tape before you grease up the bushing and the sleeve).

I learned it years ago from a YouTube video that said he learned it from none other than Mike Kojima.

You can also spray paint the sleeve and the carrier with Cerakote Microslick (the stuff they put on piston skirts) before you grease them if you want to be extra.

Those front control arms weigh 40% less than stock? Those just look like polished versions of the factory VA chassis aluminum arms with Superpro’s bushings pressed in. Is the 40% comparing to an old (non-STi) WRX stamped steel piece from an older chassis?

Also, stock caster is pretty high on these cars. Did you see an improvement with additional caster?

It went from 4.5 to around 6 degrees which isn’t that much.

I designed the overkill (and expensive) rally TCAs for GC/GR with the adjustable dovetail blocks that went from stock to 7 degree caster. 7 at the wheel end was pretty much the max on GRs for rally, you can get an extra degree on fast stages with an adjustable topmount.

Tarmac is a different beast though, lower car, lower roll center, stiffer suspensions with less travel, wider and lower profile tires.