Moving on, for the rear we decided to go with SuperPro’s HD Adjustable Lower Control Arm Package and their Rear Control Arm Upper Inner Bushings. As mentioned, when talking about the front axle lower control arms, these also bring camber adjustments to the rear and allow for the toe to be adjusted as well. The importance of being able to adjust rear toe, is to help be able to get on the throttle quicker when exiting a turn. The right amount of rear toe will allow for better mid-turn rotation while preventing understeer from overloading the front tire. Toe out in the rear can also allow for increased slip angle which is beneficial in time attack. Since sessions are short an increase in slip angle will help get the tires to the desired operating temperature quickly following the outlap. Toe-in can help reduce oversteer by creating rolling resistance and can help stability in a longer turn such as T16-18 at COTA.

It’s crucial to not have too much toe, or tires could be ruined quickly. Thankfully Mike Kojima was there to guide me to the proper amount of toe-in and toe-out, as well as the rest of the suspension geometry. So follow along in an upcoming article to see what we did! The Rear Control Arm Upper Inner Bushings helps the stability of the vehicle as well as help maintain even tire wear and allow for balanced braking. The upgrade to SuperPro’s polyurethane bushings allows for more consistent tire contact, quicker reactions, better grip as well as predictable handling characteristics compared to the OEM bushings.

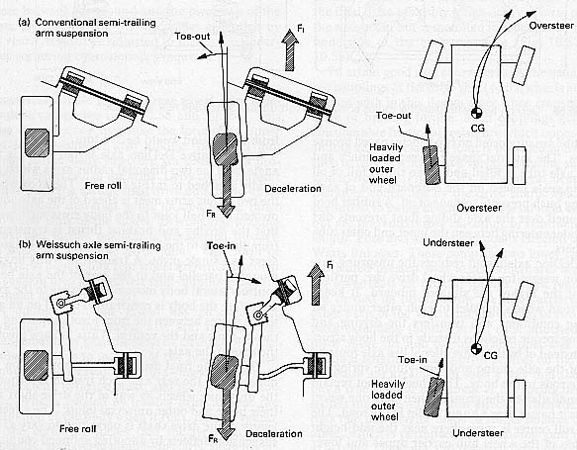

Speaking of upgrading bushings, on the rear axle we also added the Trailing Arm Forward Bushing Kit and the Trailing Arm Rearward Bushing Kit, which helps eliminate dynamic toe, improves handling and directional stability. The more stable the wheel alignment is able to stay the more traction and better tire wear we are able to maintain. Rear Subframe Mounts were also installed to help limit the twisting and flexing that can happen as the OEM rubber isolators do, which can cause the alignment and suspension to move out of the desired spec. SuperPro’s bushings ensure suspension and drivetrain components are limited to movement and prevent lost motion, which can really be felt in the rear during turning. Moving on to the differential, we decided to also add the Rear Differential Subframe Mount and the Differential Pinion Mount. The Rear Differential Subframe Mount and Differential Pinion Mount go hand in hand, both replacing OEM rubber bushings and working to reduce deflection, wheel hop and maintain the drivetrain’s proper alignment.

By providing a stiffer connection differential to subframe there’s now a quicker response during a hard acceleration load compared to the more delayed and even sluggish response the OEM bushings provide. If you’re driving a manual, it can suffer the most from load transfers as the differential can shift when the clutch is engaged/disengaged, easy fix is to add the differential pinion mount bushings. Up next is the Gearbox Cross Member Isolator Mount which is a direct replacement for the weaker OEM bushing. This will help the gearbox experience less movement which allows for more accurate shifting. Last but not least on our list is the Steering Rack Bushings Kit, which allows for a more rigid steering rack enabling steering precision and clear driver feedback during initial turn-in without the vibration that the OEM bushings allow for as they start to wear.

Bottom line is just about any time you can replace an OEM rubber bushing and more solid bushing like SuperPro’s polyurethane bushings, you’re eliminating the fear of wear and allowing for increased rigidity and improved handling. There’s also a theory that since now with the better bushings more torque is able to be sent to the wheels and isn’t being used up in other areas any longer so there for more power, better handling and better care for your car with just simple SuperPro bushing upgrades. From personal experience with testing all of this out at Super Lap Battle COTA, I would say the difference from having a completely stock suspension set up to a SuperPro/ KW set up, was night and day. Turns felt so much easier and a bit of understeer was actually welcomed for my driving style, compared to the understeer and body roll that I was plagued with prior. I’ve always understood the physics behind adding these parts on but, to actually experience it first hand was amazing. We also learned that physics plays a role when it comes to suspension geometry, which we’ll get into that more in the next article where we talk about alignment and best practices to make this work together in the most efficient way possible for Time Attack. Stay tuned!

4 comments

Any time urethane is mentioned it should automatically include the Teflon tape trick (where you put a layer of Teflon tape before you grease up the bushing and the sleeve).

I learned it years ago from a YouTube video that said he learned it from none other than Mike Kojima.

You can also spray paint the sleeve and the carrier with Cerakote Microslick (the stuff they put on piston skirts) before you grease them if you want to be extra.

Those front control arms weigh 40% less than stock? Those just look like polished versions of the factory VA chassis aluminum arms with Superpro’s bushings pressed in. Is the 40% comparing to an old (non-STi) WRX stamped steel piece from an older chassis?

Also, stock caster is pretty high on these cars. Did you see an improvement with additional caster?

It went from 4.5 to around 6 degrees which isn’t that much.

I designed the overkill (and expensive) rally TCAs for GC/GR with the adjustable dovetail blocks that went from stock to 7 degree caster. 7 at the wheel end was pretty much the max on GRs for rally, you can get an extra degree on fast stages with an adjustable topmount.

Tarmac is a different beast though, lower car, lower roll center, stiffer suspensions with less travel, wider and lower profile tires.