The spherical bearings and the heim joints all have rubber weather seals to protect them from the elements, a really nice touch that we don’t think anyone does! A final detail is that the arm is compatible with the stock knuckle or other brands of stock knuckles that use a stock-type lower mount. This can be useful if you only want to use the arm or if you have to cobble something up at an event to repair your car and keep going.

The front sway bar is a fantastic piece that incorporates all aspects of what a drift swaybar should be. Many angle kits forgo the front swaybar but we have always felt that it is critical for good handling, especially for transitions. We would have to custom make this part using Speedway Engineering torsion bars and custom fabricated arms and end links but thanks to GKTech you can now just buy an awesome part! Fortunately, GKTech has done all the thinking for you in its all-inclusive setup.

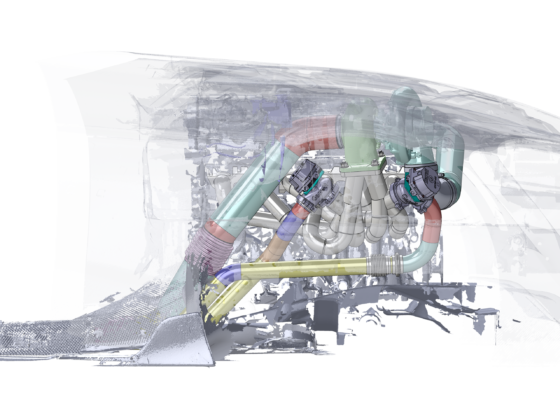

The torsion bar part of the sway bar has a bend in it to clear 2JZ and LS Swaps. It is short and splined with a 25.5mm thickness, made of 50CrV4 spring steel, a superior material to the mild stress-proof steel most bars are made from. The bar diameter may seem small but remember, stiffness is a function of length and the bar is pretty short. The bar contributes an additional 576 lbf/in to the overall front roll stiffness. The splined bar ends allow for elaborately shaped arms that give maximum tire clearance. This sway bar will not interfere with the steering angle even at 70 degrees of angle.

The end links bolt to the GKTech control arms and are 3-way adjustable to tune roll stiffness and oversteer/understeer. Spherical bearings are used in the end links instead of bushings for no play and low friction without bind. The threaded ends of the control arm side of the end link mount allow end height adjustment so you can take the bar preload out when corner-weighting the car.

7 comments

looks fanstastic! I always wondered about these arms and knuckles. Thank you for the in-depth review

“ Road racing cars need Ackerman in their front steering geometry and typically you want a gradually rising Ackerman curve that is slightly less than the geometric true Ackerman. For drifting, you want a digressive Ackerman curve. This tends to understeer in grip driving. GKTech makes 3 different knuckles. A grip driving one, a drift/grip one, and a super angle drift only one.”

^This really is ‘the secret’ to handling with rubber tires and their slip angles. In F1, I know that they even do an Anti-Ackerman setup!

https://www.f1technical.net/forum/viewtopic.php?t=8874

Until you understand these principles in theory and practice, you can’t really have a solid understanding of how to make a car handle.

It’s weird with open-wheel cars, We found that anti-Ackerman causes understeer in road racing in sedan-based cars.

I think it has everything to do with the tire. I am sure that F1 had to change up the anti-Ackerman when they switched to 18” wheel rims this year.

The ‘max lateral load’ (and associated ideal slip angles) for radial street tires is probably way different than the race rubber they run in F1. Also, downforce needs to be factored in.

My Holy Bible on tires is this book, if anyone that wants to race a car is serious about winning, or just being competitive, don’t get a HUGE REAR WING, please read the bleeping manual!

I ordered a copy and the author Paul Haney even signed it! What a guy! So happy for him to take my money!

https://www.standardsmedia.com/The-Racing-and-High-Performance-Tire-8627-book.html

I ordered the book!

they didn’t have it!

the book is out of print, considered a rare book and no one has it!