,

|

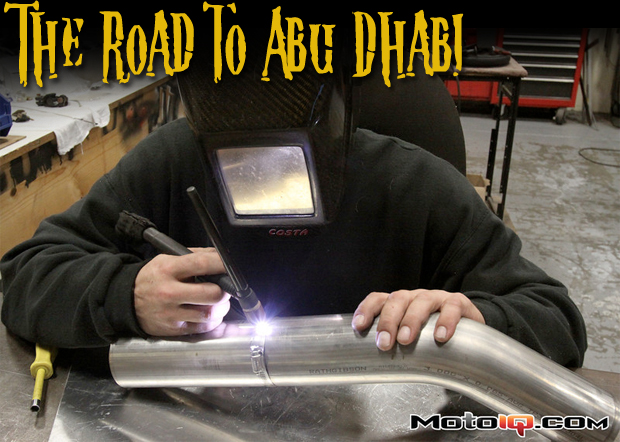

| Because it’s a large volume, it is hard to backpurge a big exhaust system with argon, the normal good practice when welding stainless. Costa instead uses flux to help prevent the weld from oxidizing from the inside. |

|

| Fabricating requires a lot of careful measuring, cutting and test fitting. Stainless must be mitered very closely and a small tungsten and filler rod used to avoid overheating the tube when welding. This require skill and patience compared to stick welding a regular mild steel muffler shop exhaust. Costa is an awesome fabricator! |

|

| One downpipe is mocked up and the other is getting fabbed to the collector. |

The decision to switch the car to turbocharging was made early. We felt that the best off the shelf turbo kit was made by Jim Wolf Technology who also pledged to provide technical support. JWT was to supply camshafts valve springs and the basic tuner’s kit which is a twin turbo kit for the Nissan VQ35DE minus the intercooler, exhaust and charge piping. We chose not to use the JWT twin intercooler system because it would not fit well behind the nose opening of our aero kit. We opted for a Greddy big single intercooler and custom piping fabricated by Costa.

|

| Costa eyeballs the fit before seam welding. |

|

| The tube ends are chamfered for better weld penetration and the ends are cleaned of oxidation for a cleaner stronger weld. |

|

| Costa uses an angle finder to get a rough approximation of the exhaust angles before any tubing is cut. |

We leave off this installment as the fabrication and assembly of the car starts! We have 5 days to get the car done, mission impossible is starting.

Sources