,

Using the Borg Warner MatchBot, you need more detailed information, basically all the information required by the equations I used along with compressor efficiency, turbine efficiency, and exhaust gas temperature. Compressor efficiency can be found on a map, but turbine efficiency has to be estimated. So you can see I estimated turbine efficiency between 65%-70%. I used 1550F-1650F for exhaust gas temperature. Using the MatchBot program involves more data and iterative work than the Garrett Boost Advisor.

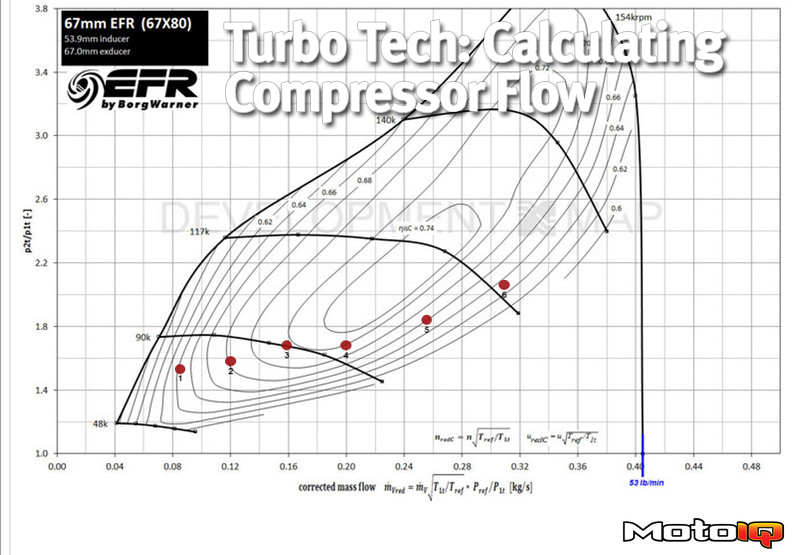

MatchBot cranks out the compressor mass flow and pressure ratios on the EFR 67mm compressor map. Using MatchBot is a bit iterative, so I had to get the points plotted on the map first and then get the efficiency values off of the map to plug into the inputs section.

MatchBot cranks out the compressor mass flow and pressure ratios on the EFR 67mm compressor map. Using MatchBot is a bit iterative, so I had to get the points plotted on the map first and then get the efficiency values off of the map to plug into the inputs section. Paired with the smallest EFR 6758 turbine, this sucker will spool pretty fast.

Paired with the smallest EFR 6758 turbine, this sucker will spool pretty fast.

So there you have it, the equations to calculate compressor mass flow and pressure ratio. If you don’t have actual data, you can typically find some data that is close. Being able to calculate where you operate on a compressor map will help you pick the correctly sized compressor wheel. For me, the GTX3067R is better sized than the GTX3071R for what I want to do because I was able to see where the data points plotted on the compressor map.