,

|

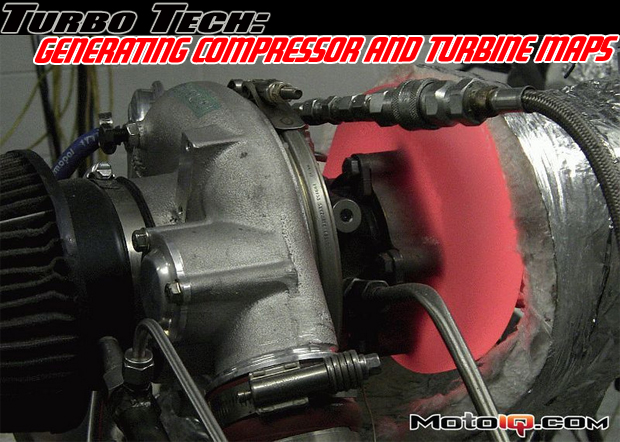

| The properties of the flows (temperature, pressure, mass flow) going into and out of the turbocharger need to be accurately measured on the gas stand in order to generate the compressor and turbine maps. On the compressor side, the properties of the air need to be measured at the inlet (1) and outlet (2). On the turbine side, the exhaust gas properties must be measured at the turbine inlet (3) and outlet (4).

|

|  |

These are the basic equations used to calculate compressor and turbine efficiencies and they are derived from the power equations. The values for the ratio of constant specific heats, k, is 1.4 for the compressor and 1.34 for the turbine side. Notice that the value for constant specific heat in the power equations is an average; this allows us to do ‘back-of-the-envelope’ calculations. To do it super accurately, you would need to look up the exact values for each temperature. Assuming an average value for hand calculations makes it much simpler.

|

| Let’s try to visualize what compressor efficiency actually looks like on a T-S (temperature-entropy) diagram. Ideal compression (100% efficient) is also known as isentropic compression meaning no change in entropy; hence, the straight vertical line representing the temperature increases without an increase in entropy. P1 and P2 are lines of constant pressure with P2 being a greater pressure than P1 of course. Actual compression that is less than 100% efficient does have an increase in entropy. As you can see on the T-S diagram, the result is a higher temperature at the end of compression. How is that extra temperature generated? By using up more power! That’s right, the more inefficient a compressor, the more power it sucks up and all that extra power just goes into heating up the air even more.

|

|

| The turbine has the opposite purpose of the compressor; the turbine expands the air from a high pressure to a low pressure and extracts energy out of the flow. That energy is converted into shaft work. In the case of a turbocharger, that shaft work powers the compressor wheel. A more efficient turbine is able to extract more energy out of the flow resulting in a lower temperature and pressure at the turbine outlet. Again, zero increase in entropy represents an ideal expansion process for a turbine. Due to inefficiency in the turbine, energy goes into increasing entropy instead of getting extracted as shaft work. The end result is a higher temperature and pressure as compared to an ideal expansion process through a 100% efficient turbine. |

Calculating turbine efficiency can be more complicated and difficult to do accurately. Remember, the compressor wheel of a turbocharger is driven by the turbine wheel which extracts power out of the exhaust flow. We can calculate the power that went into the compressor wheel and therefore know how much power ended up at the end of the shaft. So between the exhaust flow and the power put into the compressor at the end of the shaft, we lost power due to turbine and bearing system inefficiencies. How do you know how much of the power loss was in the turbine wheel and how much from the bearing system?